A solar cell dark field phase-locked thermal imaging layered micro-defect accurate characterization system and method

A technology of solar cells and thermal imaging, which is applied in image analysis, image data processing, instruments, etc., can solve problems such as the inability to obtain the difference of luminous signals on the front and rear surfaces, the inability of luminescent signals to pass through, and the depth information of defects, etc., so as to improve the detection ability and detection efficiency, high signal-to-noise ratio, and the effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

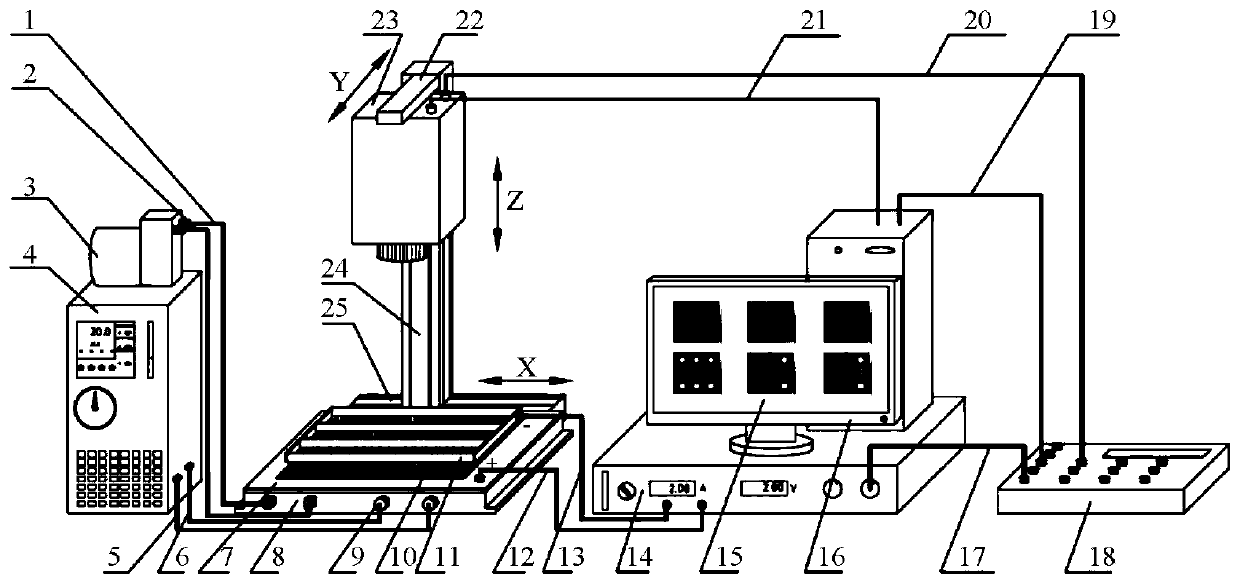

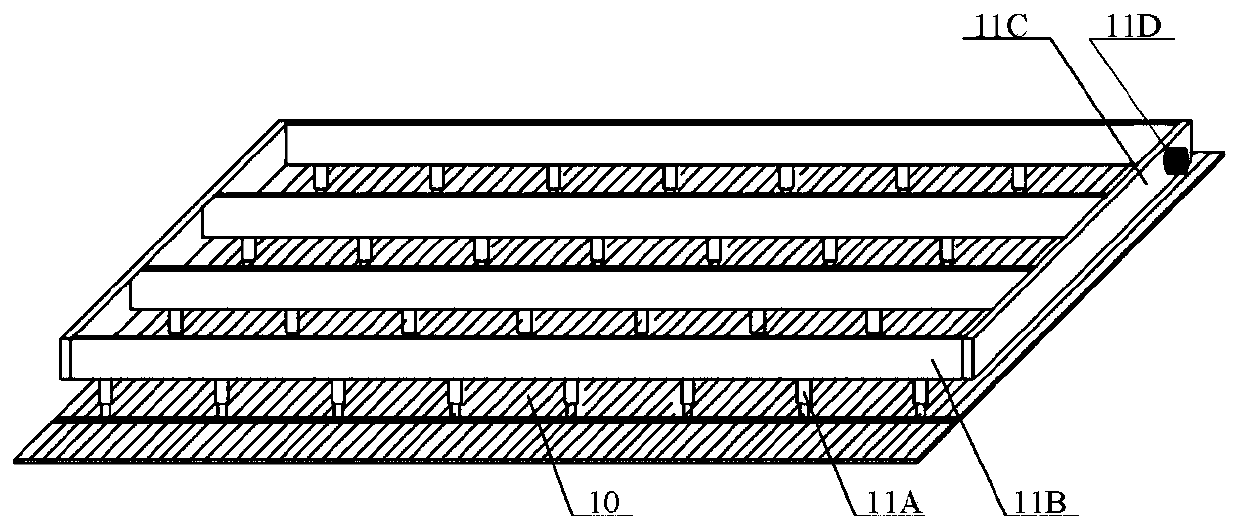

[0066] Specific implementation manner one: such as figure 1 As shown, the system for accurate characterization of solar cell stratification provided by this embodiment consists of suction hose 1, exhaust hose 2, vacuum pump 3, water-cooled pump 4, water inlet hose 5, drain hose 6, metal sample Station 7, vacuum adsorption device 8, water-cooled heat sink 9, silicon solar cell sample 10, sample fixture 11, DC power supply positive output line 12, DC power supply negative output line 13, DC power supply 14, solar cell defect layered accurate characterization It is composed of software 15, computer 16, first signal transmission line 17, data acquisition card 18, second signal transmission line 19, third signal transmission line 20, fourth signal transmission line 21, infrared thermal imager 23, and three-dimensional mobile platform. Among them:

[0067] The three-dimensional mobile platform is composed of a Y-direction mobile platform 22, a Z-direction mobile platform 24 and an X-dir...

specific Embodiment approach 2

[0079] Embodiment 2: This embodiment provides a method for accurately characterizing the micro-defects of solar cells in layers using the system described in Embodiment 1. The method measures 0° images on the front and back surfaces of the solar cell sample. , -90° image, amplitude image and phase image, and the corresponding images are subtracted to obtain the defect depth resolution result of the solar cell sample. The specific implementation steps are as follows:

[0080] Step (1): Determine the silicon solar cell sample 10 to be measured, and place it on the metal sample table 7 with the front grid facing upward;

[0081] Step (2): Turn on the vacuum pump 3 and the water-cooled pump 4, place the sample fixture 11 on the grid of the silicon solar cell sample 10, fix the sample fixture 11 so that they are in good contact, and connect the positive output line 12 of the DC power supply to The metal sample table 7 is connected, and the negative output line 13 of the DC power supply...

specific Embodiment approach 3

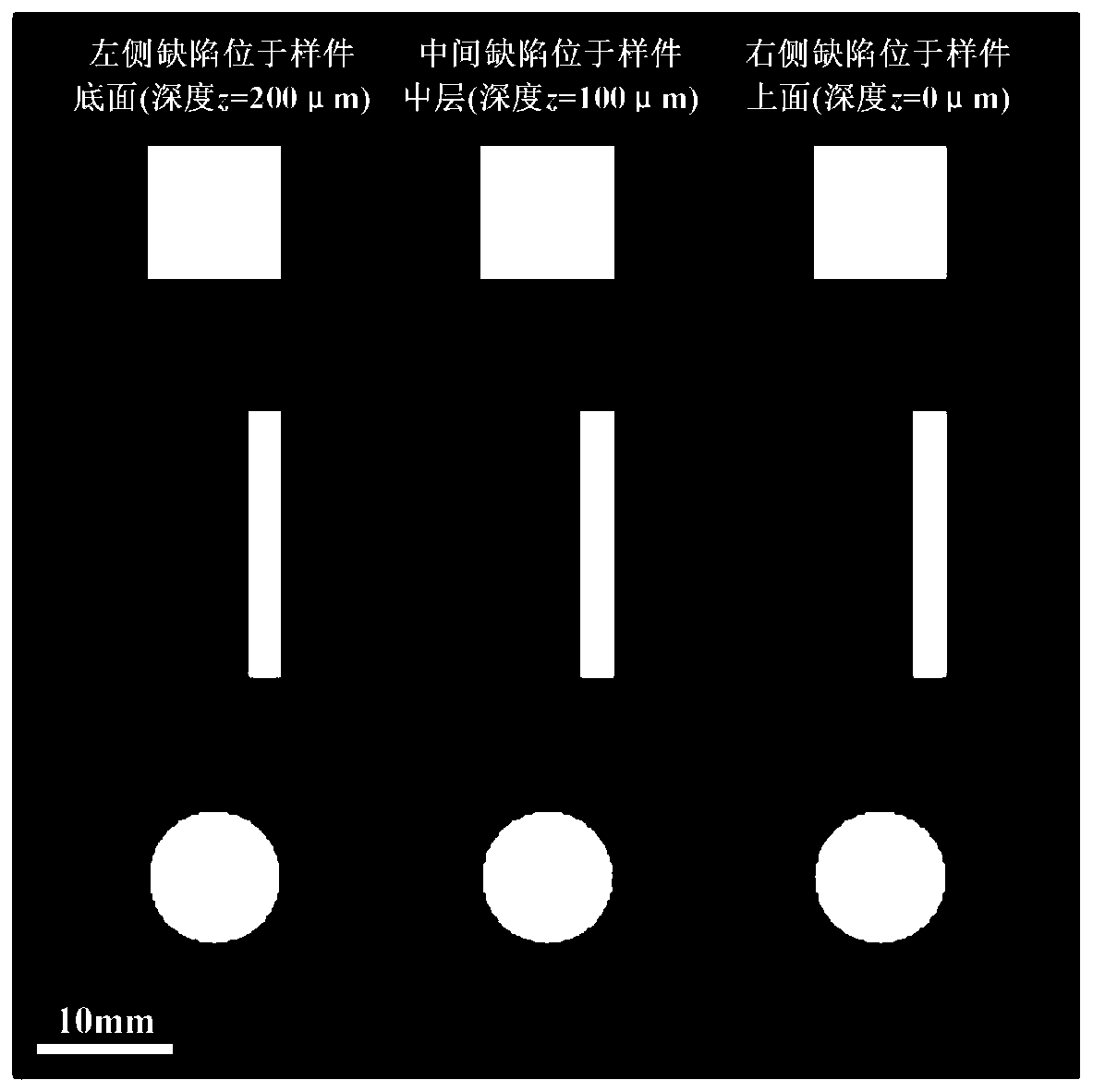

[0089] Specific implementation manner 3: This implementation manner provides a layered and accurate characterization of solar cell defects using the system described in the first implementation manner. The method uses the point spread function (PSF) to obtain 0°, -90°, amplitude, and phase images are deconvolved to obtain real and imaginary images respectively. By changing the heat source depth z defined in the point spread function, until the deconvolved imaginary image is zero or reaches the minimum, this The depth z of the heat source in the point spread function at time is the actual depth of the solar cell defect, and the depth position of the heat source can be distinguished. It includes the following steps:

[0090] Step (1): Determine the silicon solar cell sample 10 to be measured, and place it on the metal sample table 7 with the front grid facing upward;

[0091] Step (2): Turn on the vacuum pump 3 and the water-cooled pump 4, place the sample fixture 11 on the grid of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com