Method for forming image sensor

A technology for image sensors and pixel areas, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., to achieve the effects of improving image quality, reducing production costs, and reducing manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

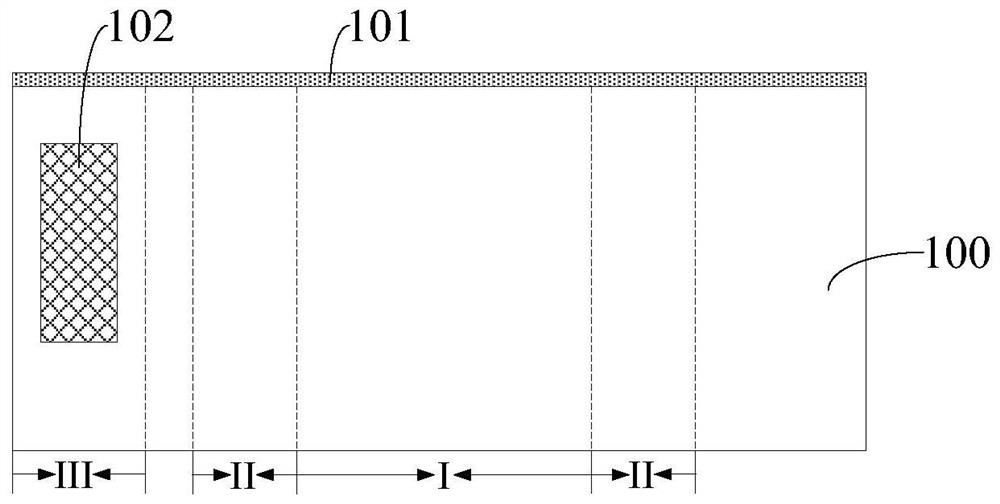

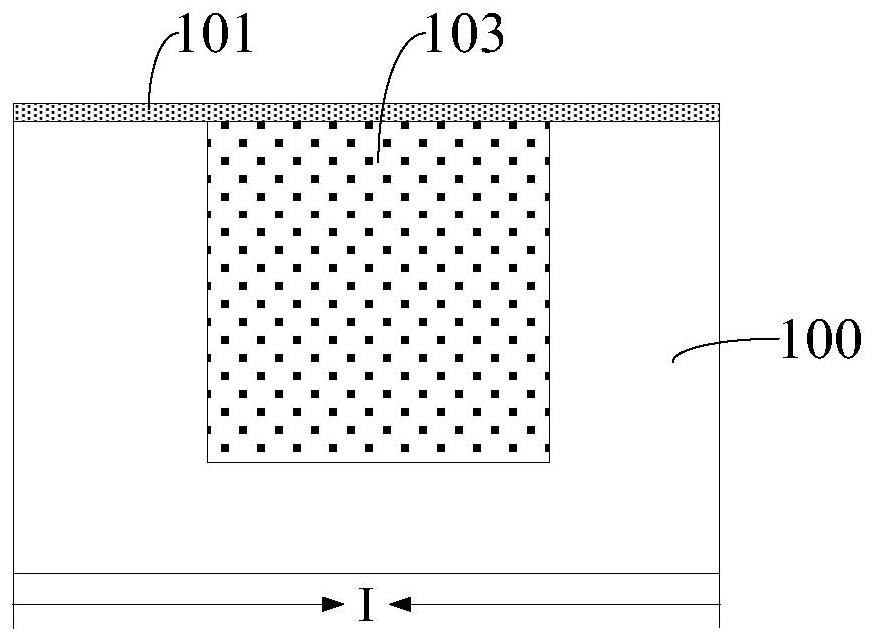

[0027] As mentioned in the background, there are still many problems in the formation process of the CMOS image sensor in the prior art. It will be specifically described below.

[0028] Theoretically, CMOS image sensors do not generate photocurrent when there is no light. However, in the manufacturing process of existing CIS products, since the photoelectric region is formed by a high-energy ion implantation process, the crystal lattice of the substrate will be damaged during the ion implantation process, so that some pixels formed subsequently will not be illuminated. Charge will also be generated, and the accumulation of charge will generate dark current (Dark Current). For a pixel unit, if its dark current value exceeds the photocurrent generated by capturing photoelectrons, the pixel unit will be considered as white noise (White Pixel), so white noise is a pixel unit with excessive dark current.

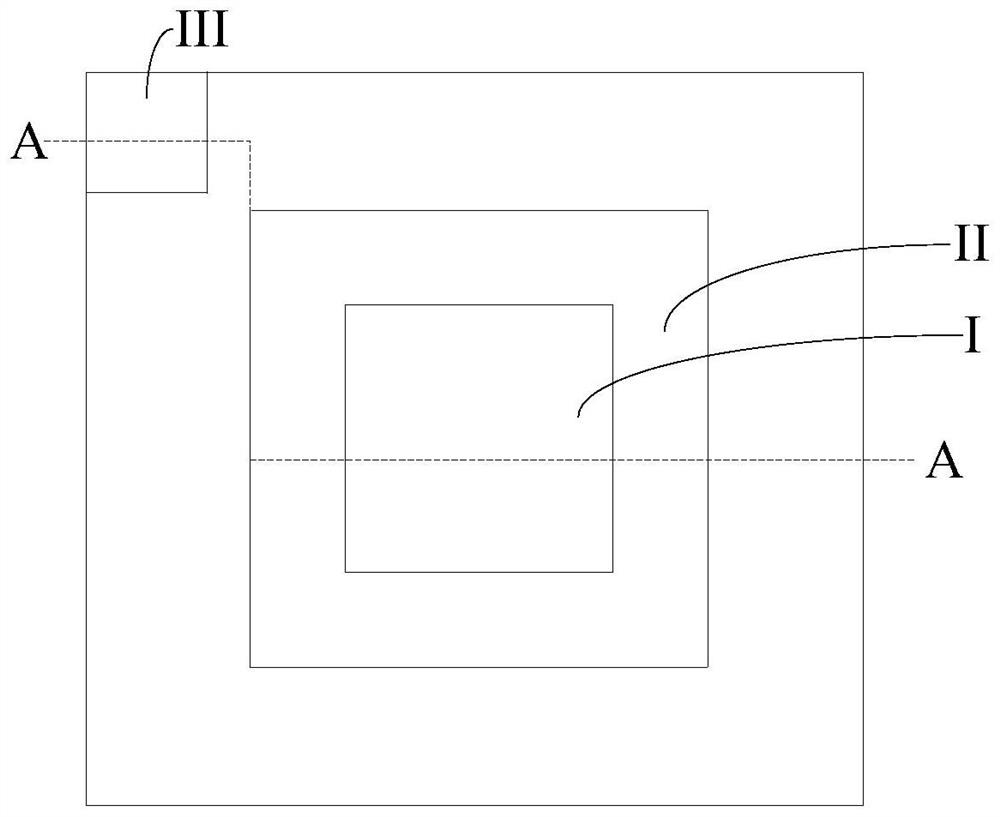

[0029] On this basis, the present invention provides a method for forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com