Method for manufacturing p-type group III nitride semiconductor

A technology of nitride semiconductor and manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of unobserved detachment and inability to obtain high carrier concentration, and achieve the effect of low resistance and realization of resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

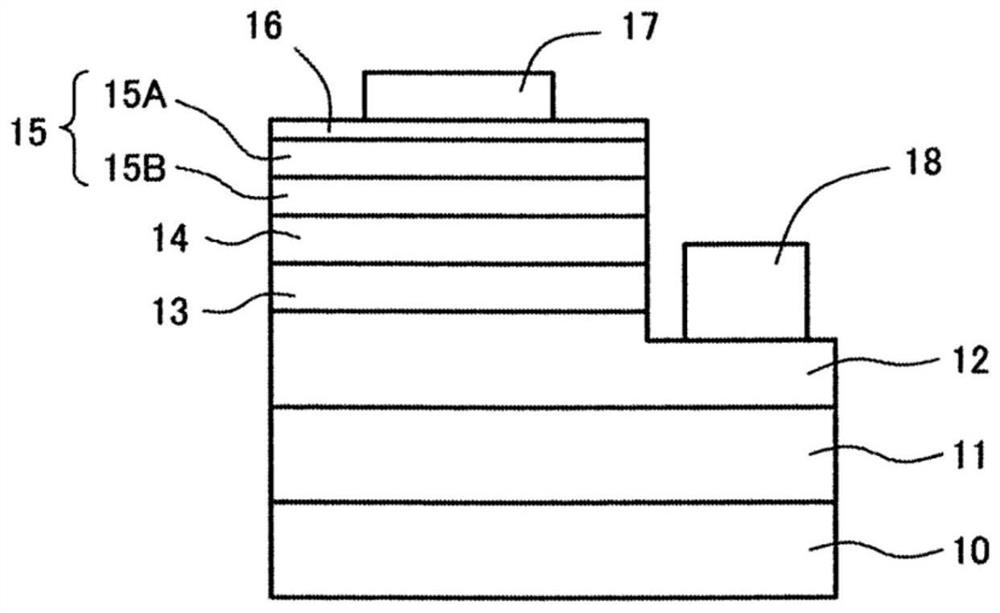

[0046] figure 1 It is a figure showing the structure of the light emitting element of Example 1. It is a flip-chip ultraviolet light-emitting element, which has a substrate 10, a buffer layer 11, an n-contact layer 12, a light-emitting layer 13, an electron blocking layer 14, a p-contact layer 15, a transparent electrode 16, a p-electrode 17, and an n-electrode 18.

[0047] (composition of each layer)

[0048] First, the configuration of each layer of the light-emitting element of Example 1 will be described.

[0049] The substrate 10 is a growth substrate made of sapphire. The thickness of the substrate 10 is, for example, 900 μm. In addition to sapphire, AlN, Si, SiC, ZnO, etc. can also be used.

[0050] The buffer layer 11 is located on the substrate 10 . The buffer layer 11 has a structure in which three layers of a core layer, a low-temperature buffer layer, and a high-temperature buffer layer are laminated in this order. The core layer is composed of undoped AlN g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com