High-nickel positive electrode material with embedded coating layer and preparation method of high-nickel positive electrode material

A technology of positive electrode material and coating layer, which is applied in the field of high nickel positive electrode material and its preparation, can solve the problems of reducing the mass specific capacity of the material, the coating material is inactive, and increasing the cost of material preparation, so as to improve the electron conduction and ion The effect of transmission, elimination of complex handling, reduction of energy consumption and cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

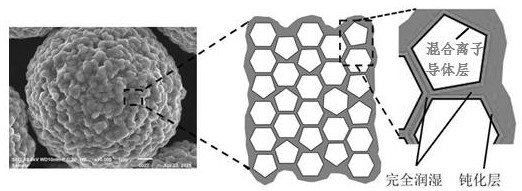

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a high-nickel positive electrode material with an embedded cladding layer, comprising the steps of:

[0035] (1) The ternary precursor Ni x co y m 1-x-y (OH) 2 , wherein 0.6 < x ≤ 0.96, 0 ≤ y < 0.4, mixed and ground with lithium source to obtain mixture A;

[0036] (2) After the mixture A is subjected to high-temperature roasting, cooling, crushing, washing and sieving, the chemical formula is LiNi x co y m 1-x-y o 2 High-nickel cathode material B;

[0037] (3) adding the high-nickel-based cathode material B into an ethanol solution of cobalt nitrate hexahydrate under the protection of an inert gas, stirring vigorously, and mixing uniformly to obtain a mixture C;

[0038] (4) Add the mixture C to the ethanol solution of sodium borohydride, and after stirring vigorously under the protection of an inert gas, the mixture is washed with absolute ethanol, filtered, and dried to obtain the embedded coating layer. High nickel cathode material. ...

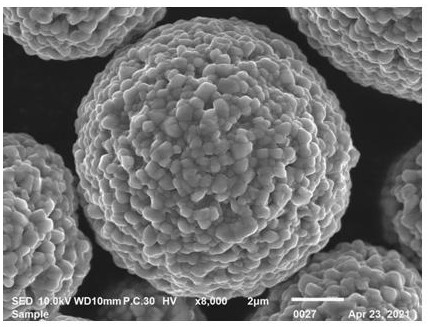

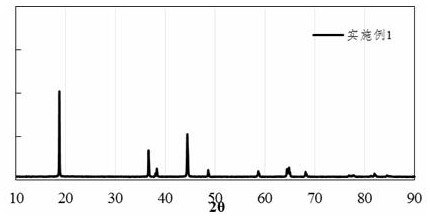

Embodiment 1

[0041] A method for preparing a high-nickel positive electrode material with an embedded cladding layer, comprising the steps of:

[0042] (1) Weigh the ternary precursor Ni 0.96 co 0.02 mn 0.01 W 0.01 (OH) 2 Mixed with LiOH, in molar ratio, LiOH:Ni 0.96 co 0.02 mn 0.01 W 0.01 (OH) 2 =1.02:1, mixture A was obtained after thorough mixing and ball milling;

[0043] (2) The mixture A is calcined at 800°C for 10 hours under an oxygen atmosphere, cooled, crushed, and sieved to obtain the chemical formula LiNi 0.96 co 0.02 mn 0.01 W 0.01 o 2 High-nickel cathode material B;

[0044] (3) Weigh 50 g of the high-nickel-based cathode material B prepared above, and add 1000 mL of 0.0291 g / mL ethanol solution of cobalt nitrate hexahydrate under vigorous stirring and argon protection to obtain a mixture C;

[0045] (4) Add 20mL of 1.5g / mL sodium borohydride ethanol solution to mixture C, stir vigorously for 3h under the protection of argon, then wash the mixture with absolute...

Embodiment 2

[0051] A method for preparing a high-nickel positive electrode material with an embedded cladding layer, comprising the steps of:

[0052] (1) Weigh the ternary precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Mixed with LiOH, in molar ratio, LiOH:Ni 0.8 co 0.1 mn 0.1 (OH) 2 =1.02:1, mixture A was obtained after thorough mixing and ball milling;

[0053] (2) The mixture A was calcined at 800°C for 10 hours under an oxygen atmosphere, cooled, crushed, and sieved to obtain the chemical formula Li Ni 0.8 co 0.1 mn 0.1 O2 high-nickel cathode material B;

[0054] (3) Weigh 50 g of the high-nickel-based cathode material B prepared above, and add 1000 mL of 0.0291 g / mL ethanol solution of cobalt nitrate hexahydrate under vigorous stirring and argon protection to obtain a mixture C;

[0055] (4) Add 20mL of 1.5g / mL sodium borohydride ethanol solution to mixture C, stir vigorously for 3h under the protection of argon, then wash the mixture with absolute ethanol for 3 times, filter, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com