Battery silicon-carbon negative electrode composite adhesive as well as preparation method and application thereof

A composite adhesive and silicon carbon technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that adhesives cannot be applied to hydrophobic carbon coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

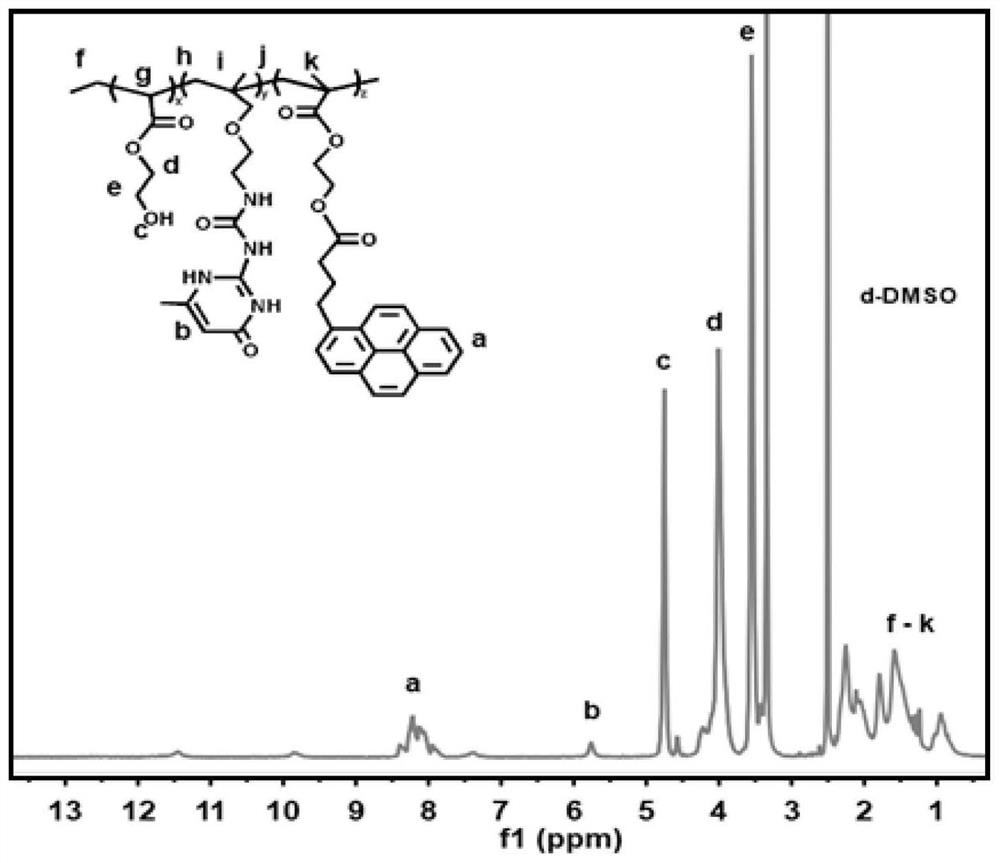

[0051] The specific preparation method of the above battery silicon carbon negative electrode composite binder comprises the following steps:

[0052] Step 1, preparing 2-urea-4-[1H]methylpyrimidinone methacrylate (UPyMA) and 2-(1-pyrenebutyryloxy)ethyl methacrylate (PyBEMA);

[0053] Preparation of 2-urea-4-[1H]methylpyrimidinone methacrylate (UPyMA) specifically comprises the following steps:

[0054] 1.1. Add a certain amount of 2-amino-4-hydroxy-6-methylpyrimidine (UPy) into a certain volume of anhydrous dimethyl sulfoxide, and stir at 90°C-170°C for 10 minutes, wait for UPy After dissolving, the solution is cooled to room temperature to form a mixed solution C;

[0055] 1.2. Add 2-isocyanatoethyl methacrylate (ICEMA) into the mixed solution C to form a mixture D;

[0056] 1.3. Use an ice bath to rapidly cool the mixture D, and precipitate a white solid E after cooling;

[0057] 1.4. The solid E was collected and washed with excess acetone, and dried under vacuum at 30°...

Embodiment 1

[0083] The invention discloses a method for preparing a battery silicon-carbon negative electrode composite binder, which comprises the following steps:

[0084] (1) Add 2g of 2-amino-4-hydroxy-6-methylpyrimidine (UPy) into 50mL of anhydrous dimethyl sulfoxide, and stir at 90°C for 10 minutes. After UPy is dissolved, the solution is cooled to Room temperature and 3.224 g of 2-isocyanatoethyl methacrylate (ICEMA) was added to the flask;

[0085] The mixture was rapidly cooled using an ice bath, upon cooling a white solid precipitated;

[0086] The precipitate was collected and washed three times with excess acetone, and dried under vacuum at 30 °C for 4 hours to obtain the monomer 2-urea-4-[1H]methylpyrimidinone methacrylate (UPyMA) (90% conversion) .

[0087](2) 2.88 g of PyBA was dissolved in 30 mL of tetrahydrofuran (THF), and 2.16 g of DCC and 0.224 g of DMAP were added thereto. After stirring for 20 minutes, 1.95 g of HEMA was added to the above mixture. After stirring...

Embodiment 2

[0096] The invention discloses a method for preparing a battery silicon-carbon negative electrode composite binder, which comprises the following steps:

[0097] (1) Add 2g of 2-amino-4-hydroxy-6-methylpyrimidine (UPy) into 50mL of anhydrous dimethyl sulfoxide, and stir at 150°C for 10 minutes. After UPy is dissolved, the solution is cooled to Room temperature and 3.224 g of 2-isocyanatoethyl methacrylate (ICEMA) were added to the flask. The mixture was rapidly cooled using an ice bath, upon cooling a white solid precipitated. The precipitate was collected and washed three times with excess acetone, and dried under vacuum at 30 °C for 4 hours to obtain the monomer 2-urea-4-[1H]methylpyrimidinone methacrylate (UPyMA) (90% conversion) .

[0098] (2) 2.88 g of PyBA was dissolved in 30 mL of tetrahydrofuran (THF), and 2.16 g of DCC and 0.224 g of DMAP were added thereto. After stirring for 20 minutes, 1.95 g of HEMA was added to the above mixture. After stirring at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

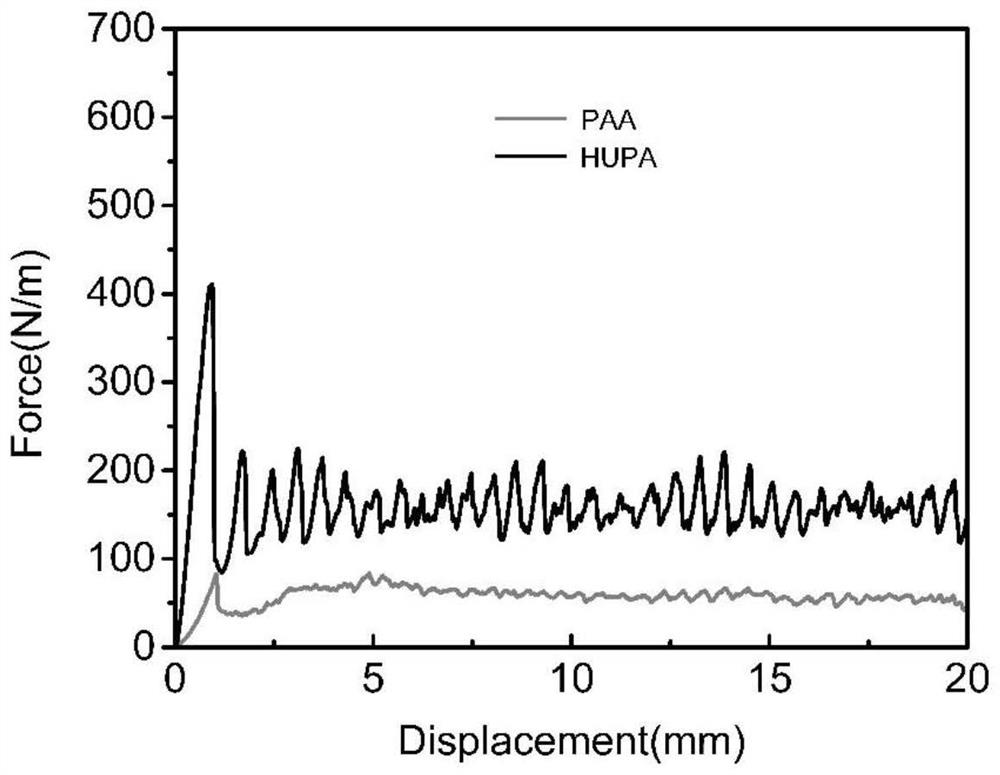

| Average peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com