Method for directly synthesizing auro-potassium cyanide by controlling level

A direct technology of potassium aurous cyanide, applied in the field of potential control, can solve problems such as inability to use potassium aurous cyanide in actual production and affecting product quality, and achieve low production cost, high product quality and fast production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

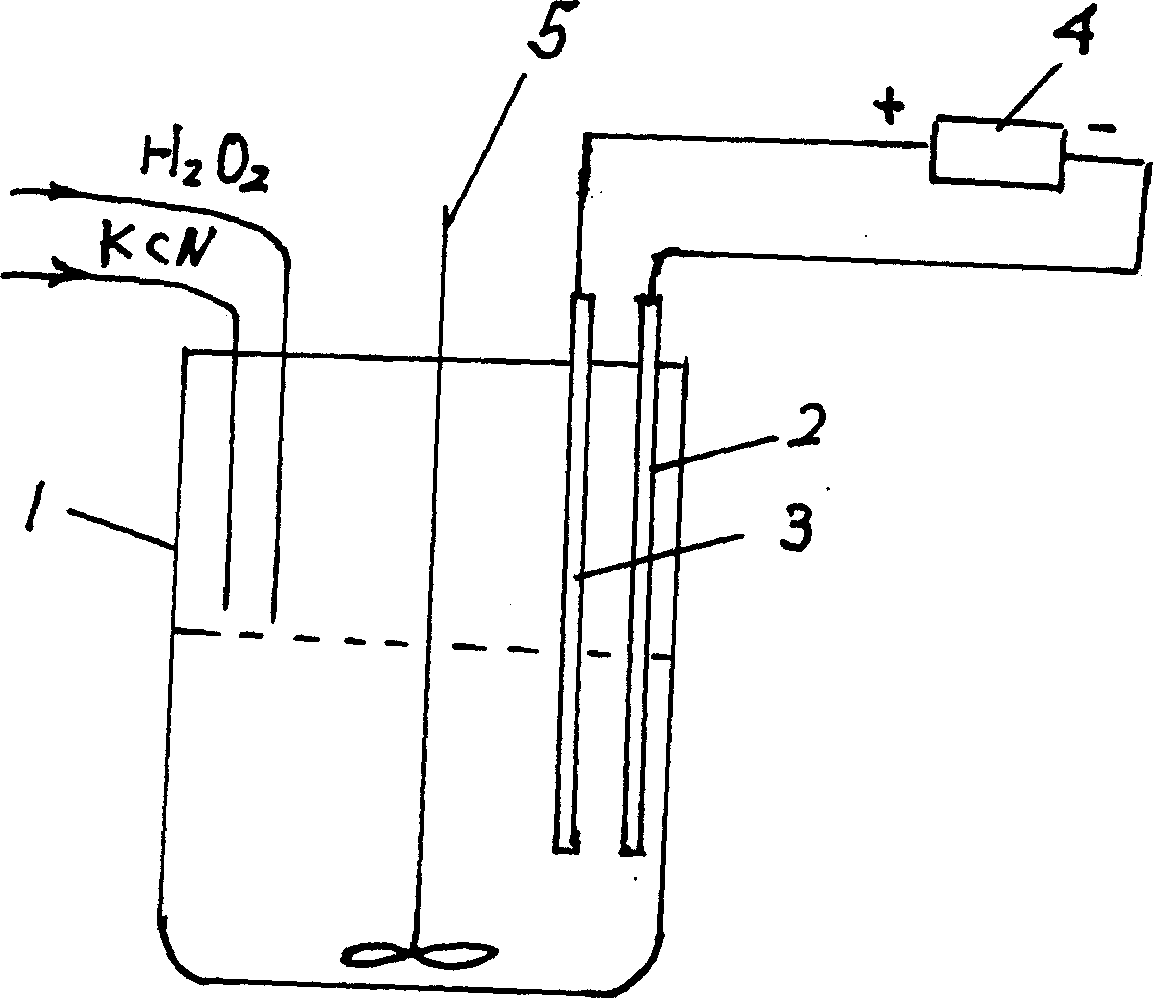

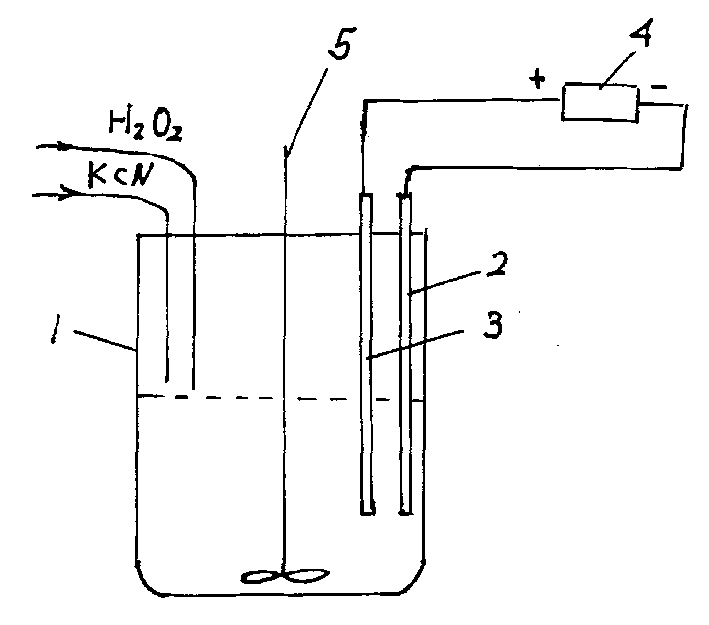

[0028] Add gold powder 1000g, pure water 2000mL in the reaction vessel 1 that stirrer 5 is housed; Heat to 60 ℃, stir, measure and show the gold potential in the reaction process with saturated calomel electrode 2, gold electrode 3, potentiometer 4, to reaction Add 30% H to container 1 2 o 2 Aqueous solution, the speed is 2-40mL / min, add 40% KCN aqueous solution, the speed is 10-20mL / min, add more KCN when the gold potential is high, and add more H when the gold potential is low 2 o 2 , control the gold potential between -600 ~ -700mv, add a total of 1.1 times the theoretical amount of KCN, and continue stirring after stopping the addition of liquid to complete the reaction. The resulting mother liquor KAu(CN) 2 Medium concentration can be as high as 30% or more. Filter the mother liquor while it is hot, cool and crystallize, centrifuge and dehydrate, wash and dry to obtain gold cyanide KAu(CN) with a purity of more than 99.9%. 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com