Water-soluble oil washing agent as well as preparation method and application thereof

A water-soluble, oil-washing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high crude oil viscosity, poor fluidity, and low recovery rate, and reduce the viscosity of crude oil and improve oil washing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

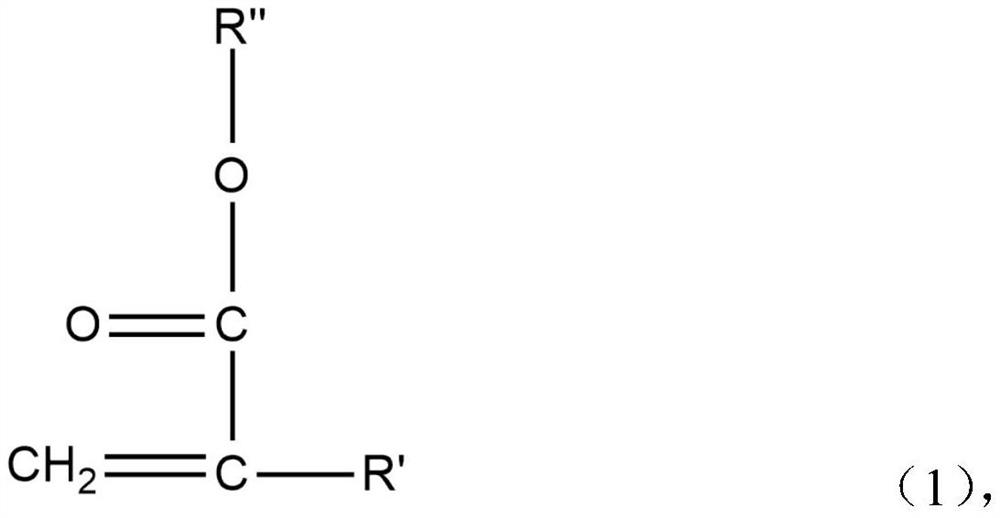

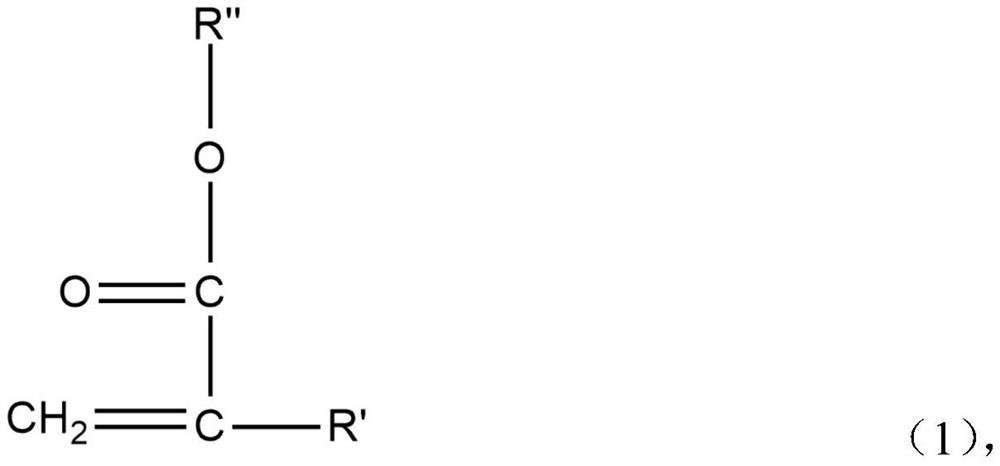

Method used

Image

Examples

Embodiment 1

[0080] Acrylic polymer A1 containing polyether structure was prepared according to the method of patent CN201811211066.X.

[0081] The preparation process of polymer A1 is as follows:

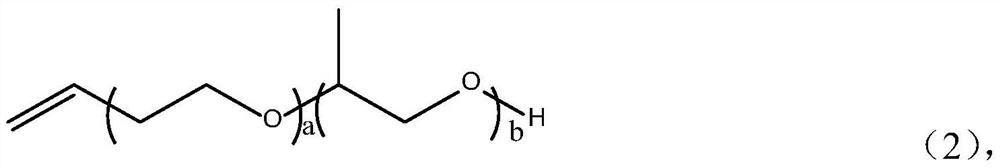

[0082] Step 1, take 10 grams of polyoxyethylene polyoxypropylene ether (number average molecular weight ≥ 2000, hydroxyl value 45mg KOH / g) with allyl alcohol as initiator, 10 grams of hydrophobic monomer (6 grams of butyl acrylate and 4 grams of methyl methacrylate) and 36 grams of cyclohexanone were added to the reactor, fully stirred until completely dissolved.

[0083] Step 2, replace the air in the reactor with nitrogen and continuously feed nitrogen, heat up to 80°C, add 0.05 g of benzoyl peroxide to start the reaction, and react at 80°C for 3.5 hours.

[0084] Step 3: Weigh 0.6 g of hydrophilic monomer acrylic acid, 0.02 g of benzoyl peroxide and 10 g of cyclohexanone, mix them uniformly, add them into the reactor, and continue to react at 80° C. for 4 hours.

[0085] Step 4, after cool...

Embodiment 2

[0087] Acrylic polymer A2 containing polyether structure was prepared according to the method of patent 201910516007.1.

[0088] The preparation process of polymer A2 is as follows:

[0089] Step 1, weigh 8 grams of polyoxyethylene polyoxypropylene ether (number-average molecular weight ≥ 2000, hydroxyl value 45 mg KOH / g) containing double bonds in the end group, 6.4 grams of butyl acrylate, 1.6 grams of 2-ethylhexyl acrylate The ester and 42 grams of toluene were added to the reactor and stirred thoroughly until completely dissolved.

[0090] Step 2, replace the air in the reactor with nitrogen and continuously feed nitrogen, heat up to 80° C., and add 0.096 g of benzoyl peroxide to start the reaction. The reaction was carried out at 80° C. for 1 hour.

[0091] Step 3, weigh 6 grams of polyoxyethylene polyoxypropylene ether with double bonds in the end group, 3.2 grams of butyl acrylate, 0.8 grams of 2-ethylhexyl acrylate, 0.3 grams of hydrophilic monomer acrylic acid, 0.06...

Embodiment 3

[0095] Preparation of modified lignin:

[0096] Step 1: Weigh 2 grams of enzymatic lignin, add 50 grams of deionized water into a three-necked flask, adjust the pH value of the solution to above 11 with 20 wt% aqueous sodium hydroxide solution, and stir until the enzymatic lignin is completely dissolved.

[0097] Step 2, under nitrogen protection, the temperature was raised to 80° C., and under constant stirring, 4 g of 3-chloro-2-hydroxypropyltrimethylammonium chloride was added dropwise to the three-necked flask, and the dropwise addition was completed in 30 minutes.

[0098] Step 3, under nitrogen protection, the reaction was continued for 4 hours at 80° C. under constant stirring.

[0099] Step 4, lower the temperature, precipitate with 1M dilute hydrochloric acid, filter, wash until the filtrate is neutral, collect the solid and vacuum-dry it to constant weight. The obtained modified lignin is brownish yellow powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com