Continuous self-heating gas production system for oil field fracturing fluid and preparation method thereof

An oilfield fracturing and self-generating heat technology, which is applied in chemical instruments and methods, heat exchange materials, drilling compositions, etc., can solve problems such as lowering the viscosity of crude oil, inability to effectively act on gas, and inability to effectively heat reservoirs with heat , to achieve the effects of reducing crude oil viscosity, destroying capillary resistance, and improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Screening of heat generation system:

[0023] The self-generating heat systems commonly used in oilfields are mainly nitrite and ammonium salts, polyhydroxy aldehyde oxidation heat generation, metal heat generation, carbonamide and nitrite, and hydrogen peroxide heat generation. The reaction equations and reaction heat generation of each substance are as follows:

[0024] NH 4 CL+NaNO 2 →NaCL+N 2 +H 2 O, ΔH=-332.58kJ / mol (1)

[0025] C 6 h 12 o 6 +CrO 3 +3H + →Cr 3+ +C 5 h 10 o 5 +CO 2 , ΔH=-107.02kJ / mol (2)

[0026] 2Na+2H 2 0→2NaOH+H 2 , ΔH=-184.8kJ / mol (3)

[0027] CO(NH 2 ) 2 +2NaNO 2 +2HCL→2NaCL+2N 2 +CO 2 +3H 2 O, ΔH=-426.00kJ / mol (4)

[0028] 2H 2 o 2 →O 2 +H 2 O, ΔH=-196.00kJ / mol (5)

[0029] By comparing different heat generation reactions, under the same mole number of reactants, the heat generation system composed of carbonamide and nitrite has the highest heat release, and 1moL carbonamide also produces 2moL nitrogen and 1moL car...

Embodiment 2

[0031] Performance evaluation of continuous self-generated heat gas production system:

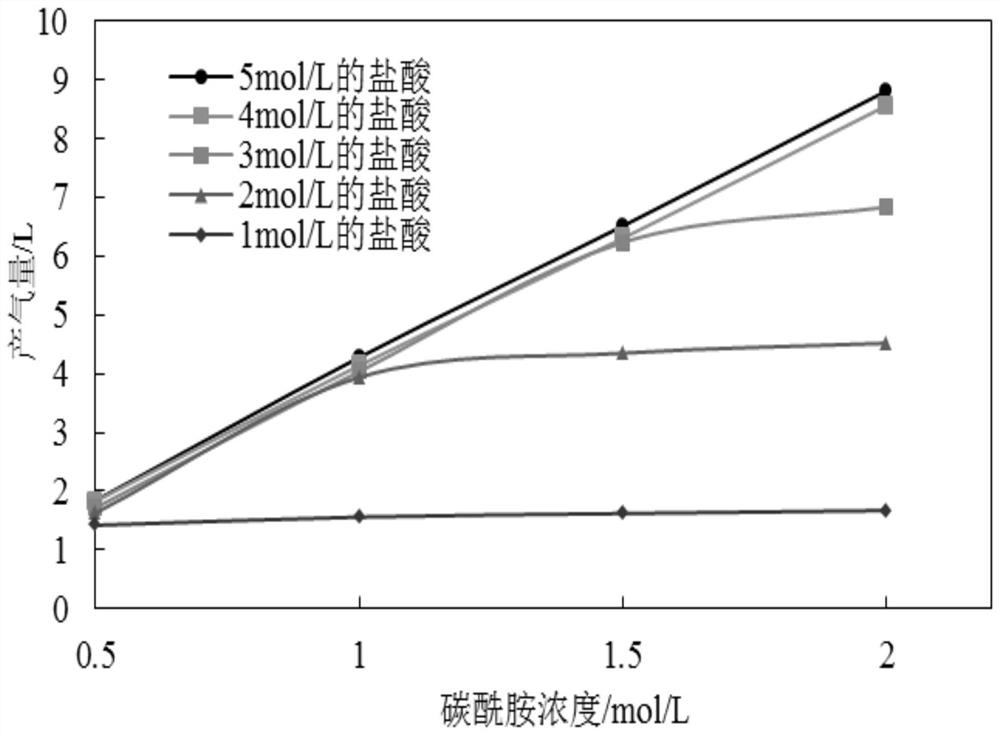

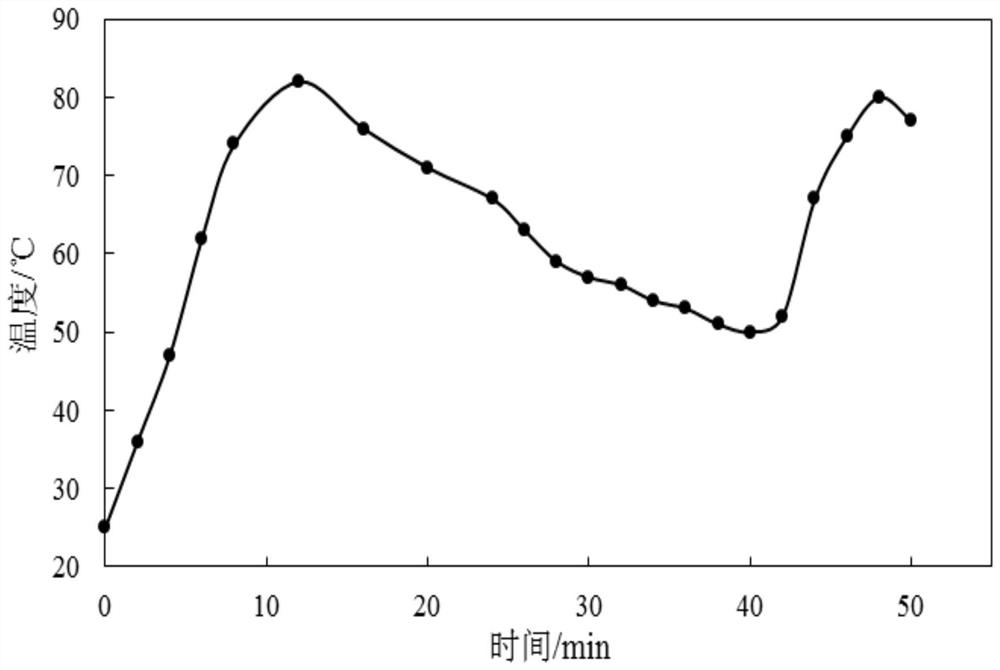

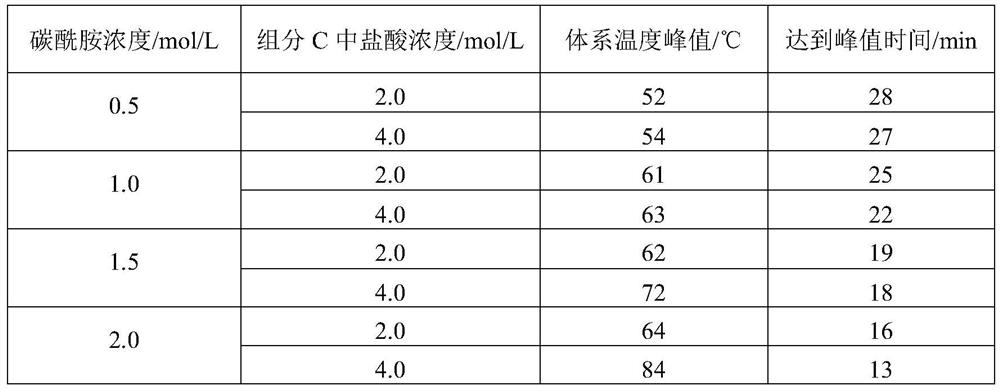

[0032] Heat generation capacity and gas production capacity are the core performances of the continuous self-generating heat and gas production system. The heat generated by the continuous self-generating heat and gas production system can increase the temperature of the fracturing fluid and the reservoir, and improve the flow capacity of the fracturing fluid and crude oil in the reservoir , the gas production capacity of the continuous self-generating heat gas production system directly affects the field use effect of fracturing fluid, and the high gas production system can effectively reduce the viscosity of crude oil and improve the oil displacement efficiency and sweep coefficient of fracturing fluid.

[0033] Therefore, it is necessary to evaluate the performance of the continuous self-generation heat generation system, and determine the proportion of each component in the continuous s...

Embodiment 3

[0044] Preparation of Emulsion in Component C

[0045] (1) Determine the amount of emulsifier

[0046] With a concentration of 5% hydrochloric acid solution as the water phase, cyclohexane as the oil phase, and Span-80 as the emulsifier, prepare the emulsion in component C, and study the optimal amount of the emulsifier. The specific process is as follows:

[0047] A 5% hydrochloric acid solution and cyclohexane were mixed and divided into 4 equal solutions;

[0048] Dyeing the mixed solution composed of hydrochloric acid and cyclohexane;

[0049] Add an equal amount of emulsifiers that are successively 500mg / L, 1000mg / L, 1500mg / L, and 2000mg / L in the mixed solution of each hydrochloric acid and cyclohexane, and stir to obtain a water-in-oil emulsion after stirring for 30min. Add the emulsion into water, and determine the optimal amount of emulsifier by observing the structure of each emulsion droplet;

[0050] It has been observed that when the emulsifier concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com