Method for hot-dipping composite coating on steel

A composite coating and hot-dip coating technology, applied in hot-dip coating process, metal material coating process, coating, etc., to achieve the effect of solving missing plating, reducing zinc consumption, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

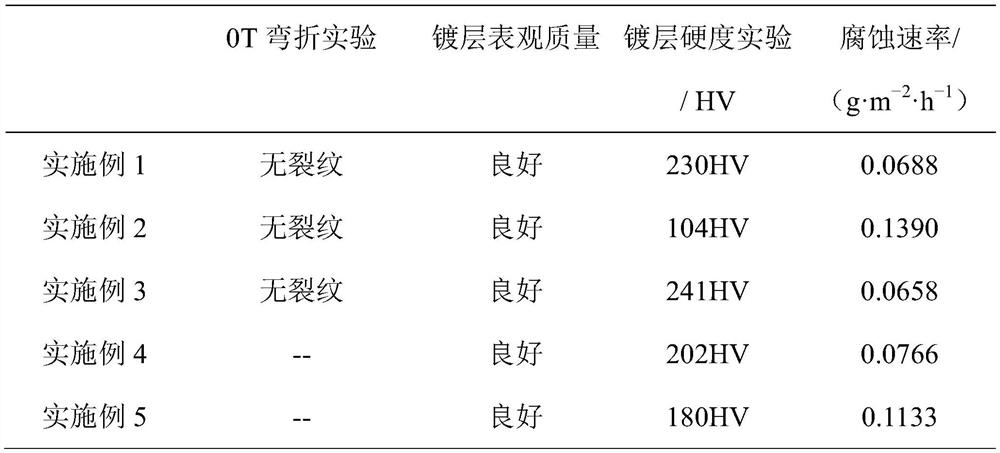

Embodiment 1

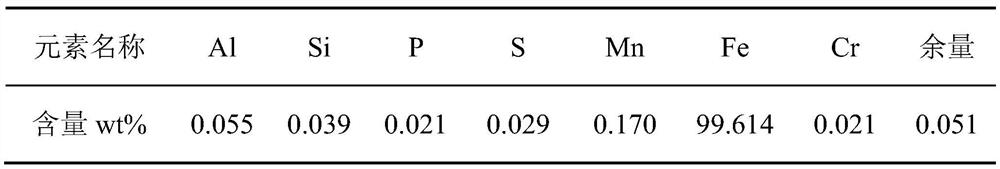

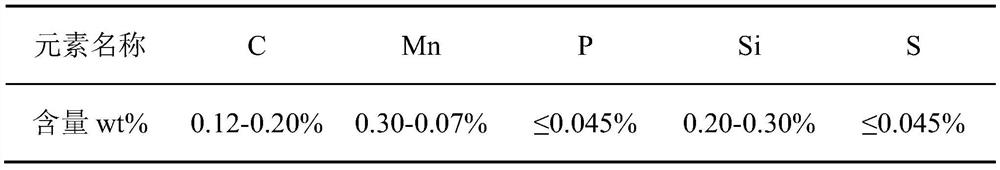

[0081] The steel used in this embodiment is 40mm×40mm×0.6mm SPHC steel plate, and a hole with a diameter of 4mm is drilled at one end of the steel plate, and iron wire is inserted to make a test piece. The specific chemical composition is shown in Table 1.

[0082] This embodiment provides a method for hot-dipping composite coatings on steel, said method comprising the following steps:

[0083] (1) First, pretreat the steel, place the steel in an alkaline washing solution, wash at 80°C for 5 minutes, the alkaline washing solution includes 100g / L of sodium hydroxide and 100g / L of sodium carbonate, and then wash with water , and then placed in the pickling solution, cleaned at 35°C for 3 minutes, the pickling solution included hexamethylenetetramine 3g / L and hydrochloric acid 1.2mol / L, and then washed with water; the pretreated steel was Flux plating at 80°C for 0.5min, the flux used included ammonium chloride 100g / L, zinc chloride 80g / L, emulsifier TX-10 0.5g / L, disodium hydrog...

Embodiment 2

[0089] The steel used in this embodiment is 40mm×40mm×1mm SPHC steel plate, and a hole with a diameter of 4mm is drilled at one end of the steel plate, and iron wire is inserted to make a test piece. The specific chemical composition is consistent with the steel described in Example 1.

[0090] This embodiment provides a method for hot-dipping composite coatings on steel, said method comprising the following steps:

[0091] (1) Firstly, the steel is pretreated, the steel is placed in an alkaline washing solution, and cleaned at 85°C for 10 minutes. The alkaline washing solution includes 150 g / L of sodium hydroxide and 50 g / L of potassium carbonate, and then washed with water , and then placed in the pickling solution, cleaned at 45°C for 5 minutes, the pickling solution included hexamethylenetetramine 10g / L and hydrochloric acid 3mol / L, and then washed with water; the pretreated steel was washed at 85 ℃ for 1 min, the flux used includes ammonium chloride 120g / L, zinc chloride ...

Embodiment 3

[0095] The steel used in this embodiment is the SPHC steel plate of 40mm × 40mm × 0.4mm, and a hole with a diameter of 4mm is drilled at one end of the steel plate, and iron wire is inserted to make a test piece. The specific chemical composition is consistent with the steel described in Example 1. .

[0096] This embodiment provides a method for hot-dipping composite coatings on steel, said method comprising the following steps:

[0097] (1) First, the steel is pretreated, the steel is placed in an alkaline washing solution, and cleaned at 83°C for 8 minutes. The alkaline washing solution includes potassium hydroxide 120g / L and sodium carbonate 75g / L, and then washed with water , and then placed in the pickling solution, cleaned at 40°C for 4 minutes, the pickling solution included hexamethylenetetramine 6g / L and hydrochloric acid 2mol / L, and then washed with water; the pretreated steel was washed at 82 ℃ for 1.5min, the flux used included ammonium chloride 110g / L, zinc chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com