Transformer oil conservator defect monitoring device and detection method based on edge calculation

An edge computing and monitoring device technology, applied in measurement devices, transformer/inductor cooling, electrical devices, etc., can solve problems such as blockage, entry, loss of protection function of the oil conservator breathing circuit, saving manpower, material resources, application The effect of broad prospects and clear judgment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with specific examples.

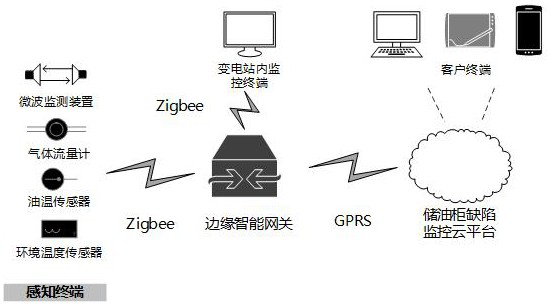

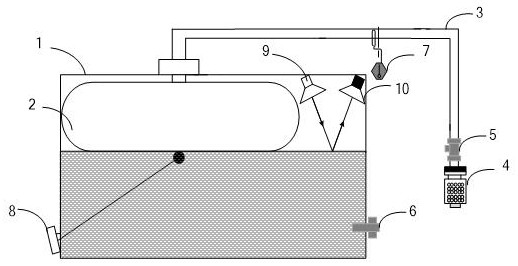

[0058] Such as figure 1 , figure 2 , a transformer oil conservator defect monitoring device based on edge computing, characterized in that it includes: a sensing terminal, an edge intelligent gateway, a monitoring terminal, an oil conservator defect monitoring cloud platform, and a client terminal, the edge intelligent gateway and the monitoring terminal They are all set in the substation, and the monitoring terminal is used to access the edge intelligent gateway. The sensing terminal includes: a gas flow meter 5, an oil temperature sensor 6, an ambient temperature sensor 7 and a microwave oil level measurement component. The gas flow The meter 5 is arranged on the breathing connecting pipe 3, the gas flow meter 5 is used to measure the breathing gas flow rate of the oil conservator, the oil temperature sensor 6 is arranged at the lower part of the side end of the oil conser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com