Near-infrared light response type slow-release composite packaging film as well as preparation method and application thereof

A near-infrared light response, composite packaging technology, applied in packaging, application, wrapping paper, etc., can solve the problems of poor preservation effect and no preservation effect, and achieve the effect of controllable release and prolonging the preservation period of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

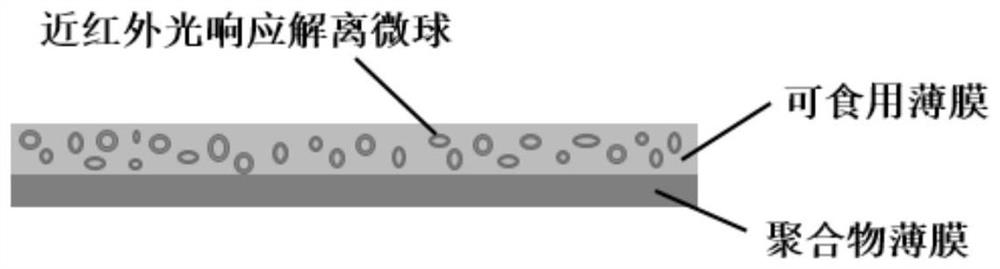

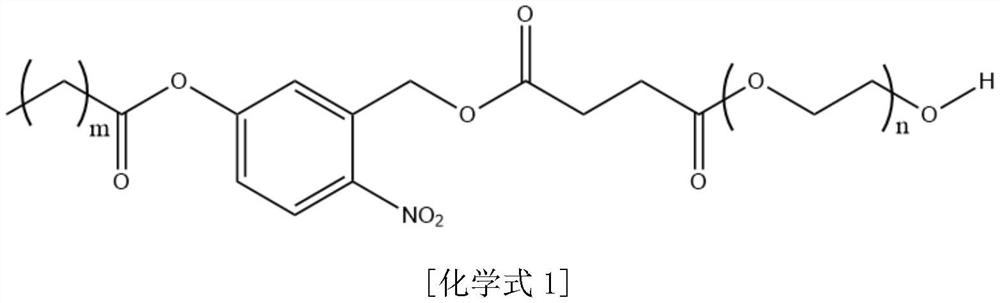

[0027] (1) Preparation of microsphere suspension: add food preservation agent and amphiphilic polymer containing o-nitrobenzyl ester structure into deionized water, and undergo high-speed homogenization to obtain microsphere suspension wrapped in food preservation agent; The weight ratio of food preservative, amphiphilic polymer and deionized water is 1:2–5:20–50;

[0028] (2) Preparation of spray solution: dissolve the base material of edible film in deionized water, then add the above-mentioned microsphere suspension and stir evenly; wherein the weight of deionized water, the base material of edible film and microsphere suspension The ratio is 50–100:5–20:2;

[0029] (3) Preparation of composite packaging film: Corona treatment is performed on the polymer film, and then the spray solution is sprayed on the corona-treated surface of the polymer film, and dried in a blast oven at 40–60°C to obtain a near-infrared light-responsive slow release composite packaging film.

Embodiment 1

[0032] This example provides a method for preparing a near-infrared light-responsive slow-release composite packaging film, specifically as follows:

[0033] (1) 1 gram of clove essential oil and 2 grams of amphiphilic polymer (m=4, n=100) containing o-nitrobenzyl ester structure are added to 50 grams of deionized water, through high-speed homogenization, to obtain the wrapped clove essential oil microsphere suspension;

[0034] (2) Dissolve 5 grams of gelatin in 100 grams of deionized water, then add 2 grams of microsphere suspension, and stir evenly;

[0035] (3) Corona treatment is performed on the polyethylene film, and then the spray solution is sprayed on the corona treated surface of the polymer film, and dried in a blast oven at 40°C to obtain a near-infrared photoresponsive slow-release composite packaging film.

[0036] The near-infrared light-responsive slow-release composite packaging film is used to store tomatoes, and then activated by near-infrared light to rel...

Embodiment 2

[0038] This example provides a method for preparing a near-infrared light-responsive slow-release composite packaging film, specifically as follows:

[0039] (1) 1 gram of cinnamon essential oil and 5 grams of amphiphilic polymer (m=18, n=20) containing o-nitrobenzyl ester structure were added to 30 grams of deionized water, and homogenized at a high speed to obtain the wrapped cinnamon essential oil microsphere suspension;

[0040] (2) Dissolve 20 grams of pectin in 80 grams of deionized water, then add 2 grams of microsphere suspension, and stir evenly;

[0041] (3) Corona treatment is performed on the polylactic acid film, and then the spray solution is sprayed on the corona-treated surface of the polymer film, and dried in a blast oven at 60° C. to obtain a near-infrared light-responsive slow-release composite packaging film.

[0042] The near-infrared light-responsive slow-release composite packaging film is used to hold oranges, and then activated by near-infrared light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com