Microbubble ultrasound contrast agent containing mitomycin C as well as preparation method and use thereof

An ultrasonic contrast agent, mitomycin technology, which is applied in echo/ultrasonic imaging agents, medical preparations containing active ingredients, and medical preparations without active ingredients, etc., can solve the problems of difficult prodrugs, etc. Improves lipid solubility, improves encapsulation efficiency and drug loading, and has clinically significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

[0037] Dissolve lecithin, mitomycin and carbon dichloride in an appropriate amount (about 100 mL), seal, shake at a constant temperature of 35°C for 4 hours, add cholesterol and oleic acid to dissolve, transfer to a rotary evaporator, add lactose, and dry by rotary evaporation. Pack in vials under aseptic conditions, 0.8g per bottle, and then inject sulfur hexafluoride gas to replace the air in the head of the vial, seal it, see figure 1 .

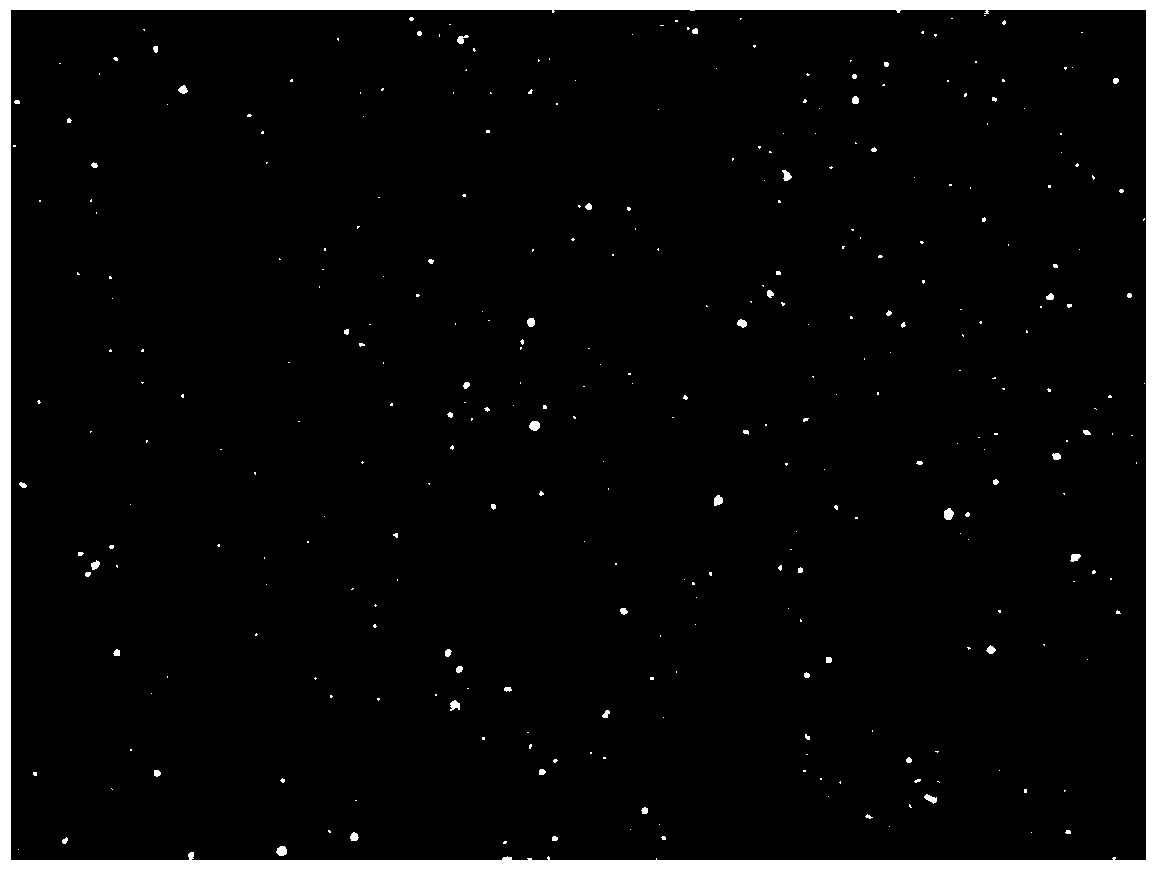

[0038] Inject 0.9% sodium chloride injection 3mL into the vial of mitomycin C microbubble ultrasound contrast agent, then shake the bottle until the microbubbles are uniformly dispersed, absorb a little, dilute 100 times with water, and observe the shape of the microbubbles under a microscope Features, it can be seen that the microbubbles are round, transparent in the middle, thin-walled, uniform in size and stable, see figure 2 . The average diameter of the obtained microbubbles measured by a laser particle size analyzer wa...

Embodiment 2

[0040]

[0041] Dissolve lecithin, mitomycin and an appropriate amount of ethanol (about 100 mL), seal, shake at a constant temperature of 50°C for 6 hours, add vitamin E to dissolve, transfer to a rotary evaporator, add mannose, and dry by rotary evaporation. Under aseptic conditions, it is divided into vials, 0.8g per vial, and then injected with sulfur hexafluoride gas to replace the air in the head of the vial, and then sealed.

Embodiment 3

[0043]

[0044] Dissolve dipalmitoylphosphatidylcholine, dipalmitoylphosphatidylethanolamine, mitomycin and chloroform in an appropriate amount (about 100mL), seal, shake at a constant temperature at 40°C for 6h, add oleic acid to dissolve, transfer to a rotary evaporator, add Sorbitol, dried by rotary evaporation. It is divided into vials under sterile conditions, 0.8g per vial, and then injected with perfluoropropane gas to replace the air in the head of the vial, and then sealed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com