Method for preparing sodium electrode based on sodium salt boiling method

A technology of electrode and sodium salt, which is applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of environmental pollution, unfavorable mass production, etc., and achieve the effect of simple process, excellent sodium storage performance, and increasing the distance between graphite layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

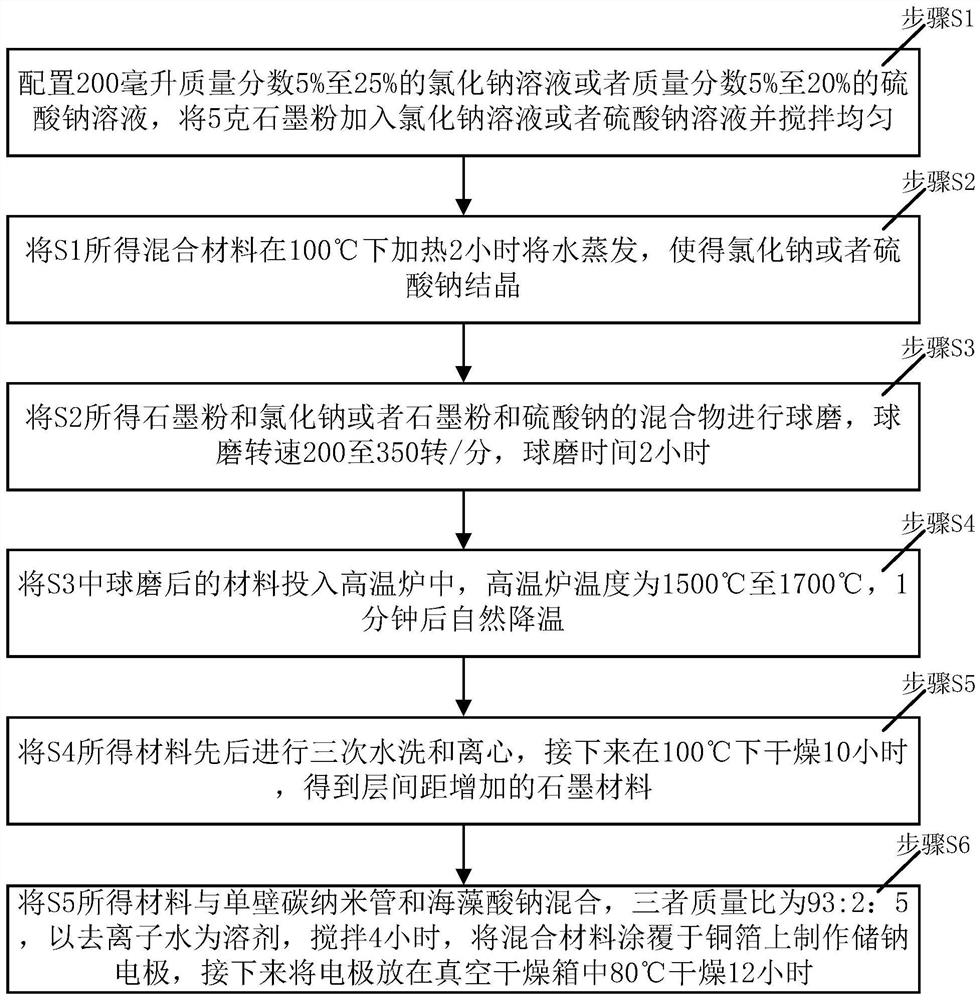

[0029] see figure 1 , shown as the flow chart of a method for preparing a sodium electrode based on the sodium salt boiling method proposed by the present invention, comprising the following steps:

[0030] S1, configure 200 ml of sodium chloride solution with a mass fraction of 5% to 25% or a sodium sulfate solution with a mass fraction of 5% to 20%, add 5 grams of graphite powder to the sodium chloride solution or sodium sulfate solution and stir evenly;

[0031] S2, heating the mixed material obtained in S1 at 100° C. for 2 hours to evaporate the water to crystallize sodium chloride or sodium sulfate;

[0032] S3, ball milling the mixture of graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com