Method for preparing 1, 4-diaminoanthraquinone-2-sulfonic acid by using supergravity reactor

A high-gravity reactor, diaminoanthraquinone technology, applied in chemistry/physics/physicochemical fixed reactor, sulfonic acid preparation, organic chemistry, etc., can solve the problem of difficult waste liquid treatment, complex temperature control, system Problems such as low pH, to achieve the effect of solving uneven temperature distribution and temperature monitoring, high yield and purity, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

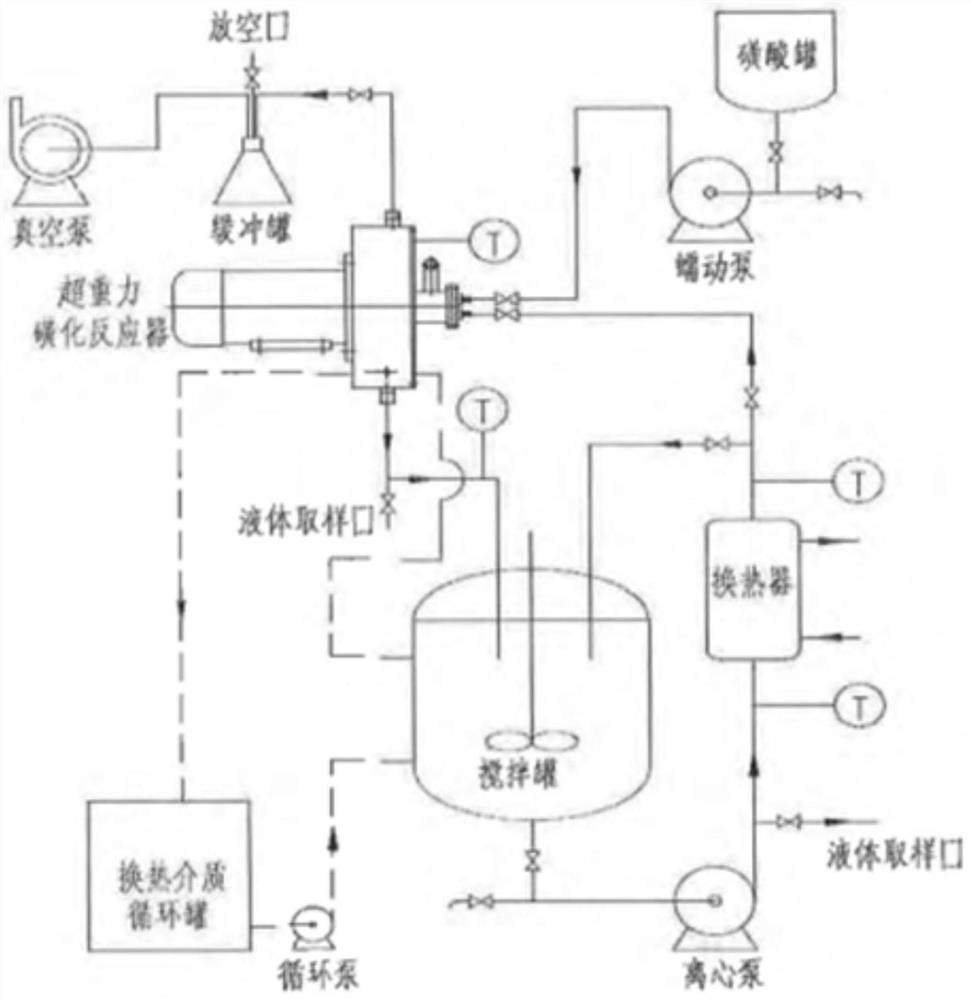

Image

Examples

Embodiment 1

[0023] In the high-gravity reactor, 1,4-diaminoanthraquinone leuco is used as the raw material, o-dichlorobenzene is used as the solvent, and the temperature is raised under negative pressure to remove trace moisture in the system. , the weight ratio of 4-diaminoanthraquinone leuco is 8:1, the supergravity level of the supergravity reactor is 600g, and the feed rate of 1,4-diaminoanthraquinone leuco is 30kg / h; Oxidize and sulfonate 1,4-diaminoanthraquinone leuco with chlorosulfonic acid, the molar ratio of chlorosulfonic acid to 1,4-diaminoanthraquinone leuco is 3.5:1, and the sulfonation temperature is 90°C , the sulfonation time is 3h; in the later stage of sulfonation, the auxiliary agent thionyl chloride is also added, and the ratio of its dosage to the weight of 1,4-diaminoanthraquinone leuco body is 1:50; the obtained material is neutralized and distilled to remove After solvent, filtration, and acidification treatment, the precipitated material was drained and washed to...

Embodiment 2

[0025] In the high-gravity reactor, 1,4-diaminoanthraquinone leuco is used as the raw material, and nitrobenzene is used as the solvent, and the temperature is raised under negative pressure to remove trace moisture in the system, and the o-dichlorobenzene solvent and 1, The weight ratio of 4-diaminoanthraquinone leuco is 8:1, the supergravity level of the supergravity reactor is 500g, and the feed rate of 1,4-diaminoanthraquinone leuco is 25kg / h; Chlorosulfonic acid oxidizes and sulfonates 1,4-diaminoanthraquinone leuco, the molar ratio of chlorosulfonic acid to 1,4-diaminoanthraquinone leuco is 3.5:1, and the sulfonation temperature is 90°C. The sulfonation time is 3 hours; in the later stage of sulfonation, the auxiliary agent thionyl chloride is added, and the ratio of its dosage to the weight of 1,4-diaminoanthraquinone leuco body is 1:50; the obtained material is neutralized and distilled to remove the solvent , filtration to remove impurities, and acidification treatmen...

Embodiment 3

[0027] In the high-gravity reactor, 1,4-diaminoanthraquinone leuco is used as the raw material, o-dichlorobenzene is used as the solvent, and the temperature is raised under negative pressure to remove trace moisture in the system. , the weight ratio of 4-diaminoanthraquinone leuco is 10:1, the supergravity level of the supergravity reactor is 600g, and the feed rate of 1,4-diaminoanthraquinone leuco is 30kg / h; Oxidize and sulfonate 1,4-diaminoanthraquinone leuco with chlorosulfonic acid, the molar ratio of chlorosulfonic acid to 1,4-diaminoanthraquinone leuco is 3.5:1, and the sulfonation temperature is 100°C , the sulfonation time is 3h; in the later stage of sulfonation, the auxiliary agent thionyl chloride is also added, and the ratio of its dosage to the weight of 1,4-diaminoanthraquinone leuco body is 1:50; the obtained material is neutralized and distilled to remove After solvent, filtration, and acidification treatment, the precipitated material was drained and washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com