Green separation and purification method and application of blueberry polysaccharide

A technology for separation and purification of polysaccharides, applied in the field of green separation and purification of blueberry polysaccharides, which can solve the problems of blueberry polysaccharides with many impurities, organic residues, and complicated separation and purification methods, and achieve high purity, improved product quality, and simple and uncomplicated methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

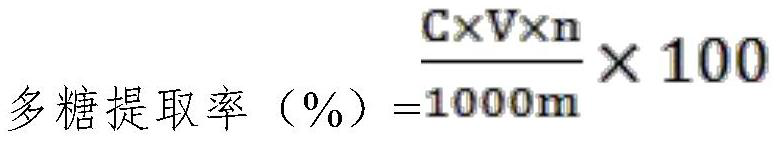

[0090] A green separation and purification method of blueberry polysaccharides, comprising the following steps:

[0091] (1) Sample separation: The crude extract of blueberry anthocyanins is applied to the column by wet method through macroporous resin, let stand for adsorption, and then eluted with distilled water, and the polysaccharide is detected by the phenol-sulfuric acid method until the elution solution is sugar-free. Split out, and then concentrate the blueberry polysaccharide eluate to obtain blueberry polysaccharide extract; the quality of the blueberry anthocyanin crude extract and resin is applied to the column according to the ratio of 1:30 wet method, and the elution time is 60min; the concentration temperature is 63°C;

[0092] (2) Alcohol precipitation: dissolve the blueberry polysaccharide extract of step (1) with hot distilled water, then add ethanol under stirring, and after standing overnight, filter and collect the precipitate; the temperature of the dist...

Embodiment 2

[0097] A green separation and purification method of blueberry polysaccharides, comprising the following steps:

[0098] (1) Sample separation: The crude extract of blueberry anthocyanins is applied to the column by wet method through macroporous resin, let stand for adsorption, and then eluted with distilled water, and the polysaccharide is detected by the phenol-sulfuric acid method until the elution solution is sugar-free. Split out, and then concentrate the blueberry polysaccharide eluate to obtain blueberry polysaccharide extract; the quality of the blueberry anthocyanin crude extract and resin is applied to the column according to the ratio of 1:30 wet method, and the elution time is 65min; the concentration temperature is 68°C;

[0099] (2) Alcohol precipitation: dissolve the blueberry polysaccharide extract of step (1) with hot distilled water, then add ethanol under stirring, and after standing overnight, filter and collect the precipitate; the temperature of the dist...

Embodiment 3

[0104] A green separation and purification method of blueberry polysaccharides, comprising the following steps:

[0105] (1) Sample separation: The crude extract of blueberry anthocyanins is applied to the column by wet method through macroporous resin, let stand for adsorption, and then eluted with distilled water, and the polysaccharide is detected by the phenol-sulfuric acid method until the elution solution is sugar-free. Separate the flow, and then concentrate the blueberry polysaccharide eluate to obtain blueberry polysaccharide extract; the quality of the blueberry anthocyanin crude extract and resin is applied to the column according to the ratio of 1:30 wet method, and the elution time is 61min; the concentration temperature is 64°C;

[0106] (2) Alcohol precipitation: dissolve the blueberry polysaccharide extract of step (1) with hot distilled water, then add ethanol under stirring, and after standing overnight, filter and collect the precipitate; the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com