Steel pipe ring piece capable of achieving rapid freezing of stratum and machining method of steel pipe ring piece

A processing method and technology of steel pipe sheet, which can be applied in underground chambers, earthwork drilling, and detection of fluid appearance at leakage points, etc., can solve the problems of complex and time-consuming oil filling process, and achieve processing cost and processing difficulty Low, reduce erosion, ensure the effect of effective service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

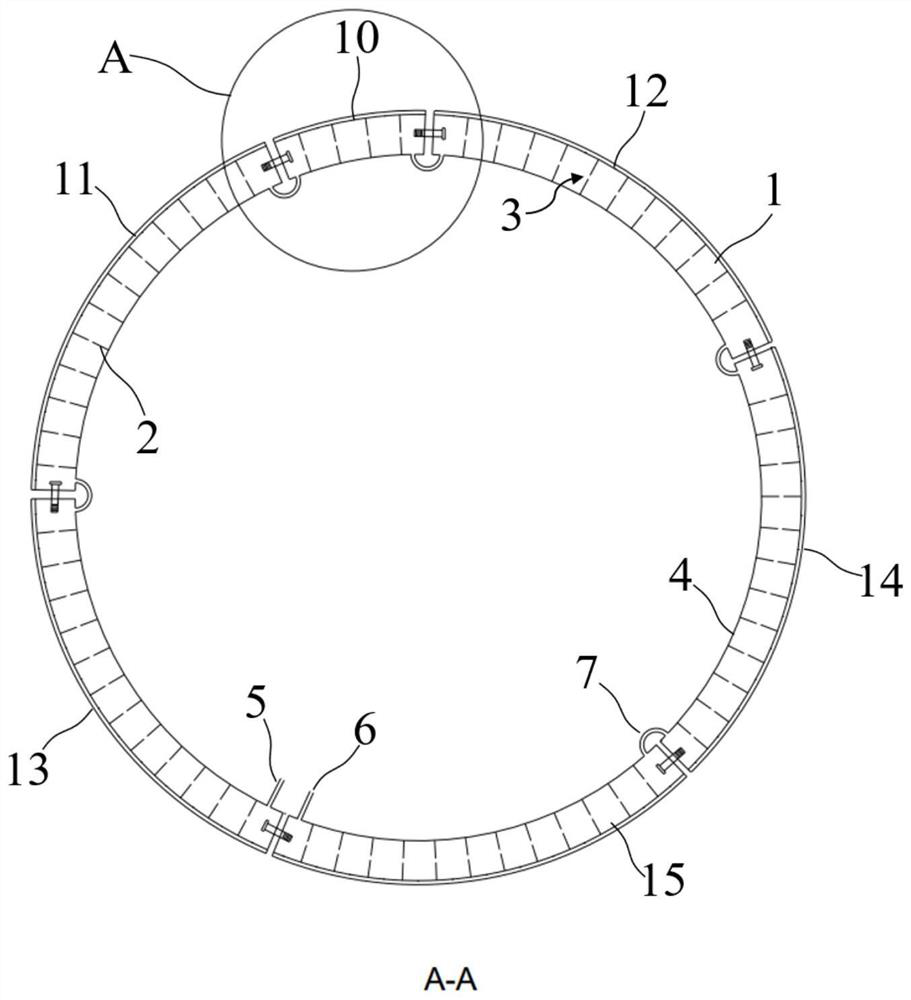

[0056] The steel pipe annulus that realizes quick freezing of the formation in this embodiment includes:

[0057] There are several arc-shaped steel pipe sheets 1, which are sequentially connected to form steel pipe ring sheets;

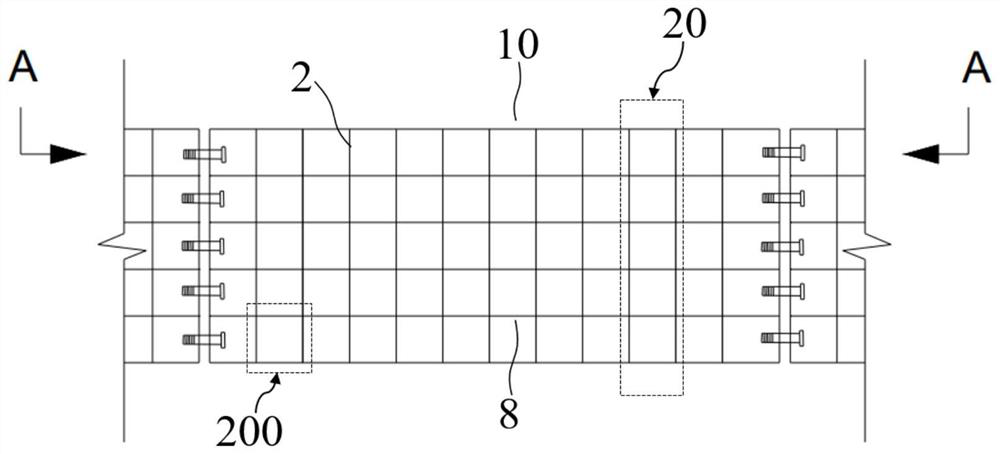

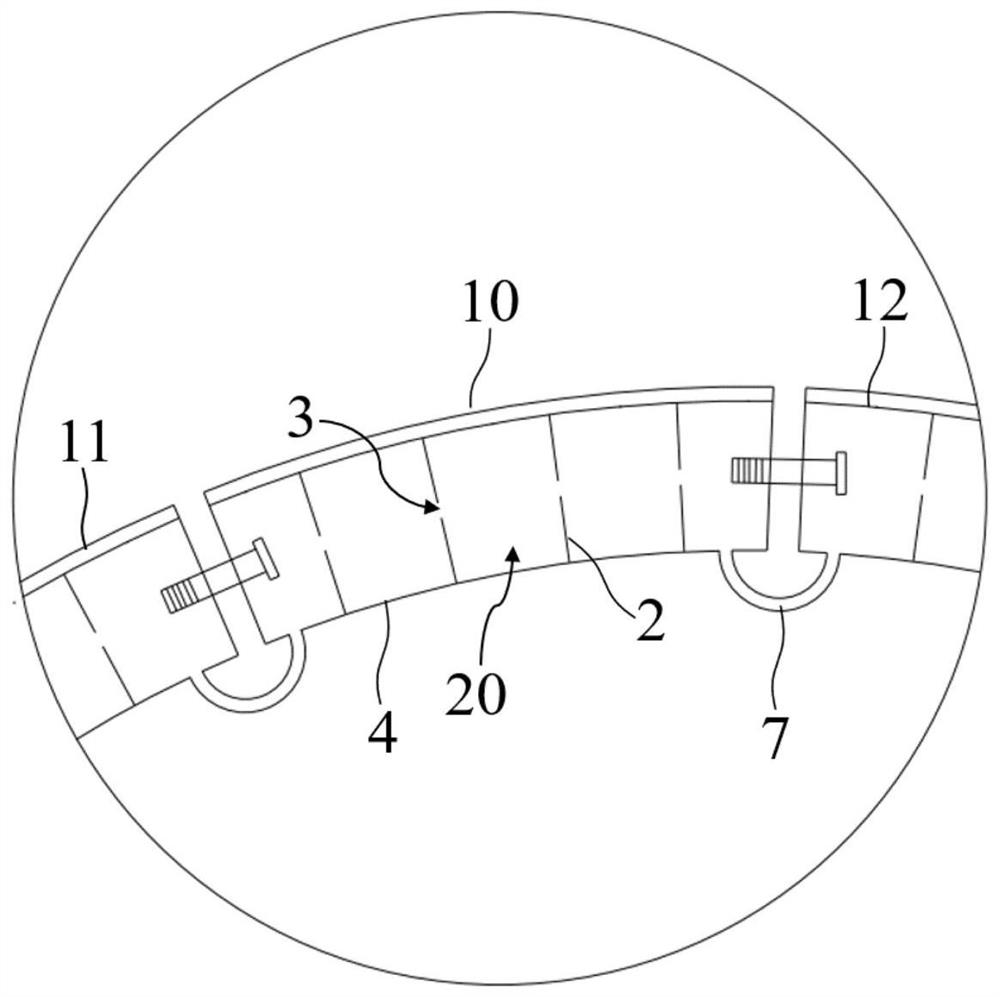

[0058] The rib plate 2 is fixedly connected to the inner surface of the arc-shaped steel pipe sheet 1 in a manner perpendicular to the inner surface of the arc-shaped steel pipe sheet 1, the length direction of the rib plate 2 is arranged along the width direction of the arc-shaped steel pipe sheet 1, and the rib plate There are several plates 2 arranged at intervals, and a rib cavity 20 is formed between 2 adjacent rib plates;

[0059] Also includes:

[0060] A communication hole 3, which runs through each rib 2, and communicates with adjacent rib cavities 20;

[0061] A sealing plate 4, which is arranged on one side of the inner surface of the arc-shaped steel pipe sheet 1, and is used to seal each rib cavity 20;

[0062] The water inlet port 5 ...

Embodiment 2

[0067] In this embodiment, the steel pipe ring piece for quick freezing of the formation is further improved on the basis of Embodiment 1, and further includes:

[0068] The connecting channel 7 communicates with the two rib cavities 20 at the joint ends of two adjacent arc-shaped steel pipe sheets 1 .

[0069] like figure 2 , image 3 and Figure 4 As shown, the end plates of each arc-shaped steel pipe sheet 1 do not have communication holes. In order to ensure the fluidity of the internal refrigerant and ensure the heat exchange efficiency, this embodiment is provided with a connecting channel 7, connecting the rib cavity 20 at the end of one arc-shaped steel pipe sheet 1 to the other corresponding to it. The rib cavity 20 at the end of the connected arc-shaped steel pipe sheet 1 is connected, so that after each arc-shaped steel pipe sheet 1 is spliced into a ring, a refrigerant circuit is formed between each arc-shaped steel pipe sheet 1, and the entire steel pipe rin...

Embodiment 3

[0074] The steel pipe ring sheet for rapid freezing of the ground in this embodiment is further improved on the basis of Embodiment 2, the water inlet port 5 and the water outlet port 6 are respectively connected to the two ribs at the ends of the adjacent two arc-shaped steel pipe sheets 1 Cavity 20 communicates;

[0075] No connecting pipe 7 is provided at the joint ends of two adjacent arc-shaped steel pipe sheets 1 provided with a water inlet port 5 and a water outlet port 6 .

[0076] like figure 2 and Figure 4 As shown, the water inlet port 5 and the water outlet port 6 are respectively arranged at the ends of two different adjacent arc-shaped steel pipe sheets 1, and there is no connection channel 7 at the junction here, and the frozen water flowing in from the water inlet port 5 The liquid will completely flow through the entire steel pipe ring to ensure the fluidity of the refrigerant everywhere in the steel pipe ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com