Double-layer contact type heat-conducting high-power power supply pressure-bearing shell for large water depth

A technology of high-power power supply and pressure-bearing shell, which is applied in the direction of output power conversion device, electrical equipment shell/cabinet/drawer, electrical components, etc., which can solve the problems of high difficulty, high heat dissipation efficiency, and low heat conduction efficiency. Achieve the requirements of reducing the machining accuracy of the guide rail, improve the sealing and anti-corrosion ability, and improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

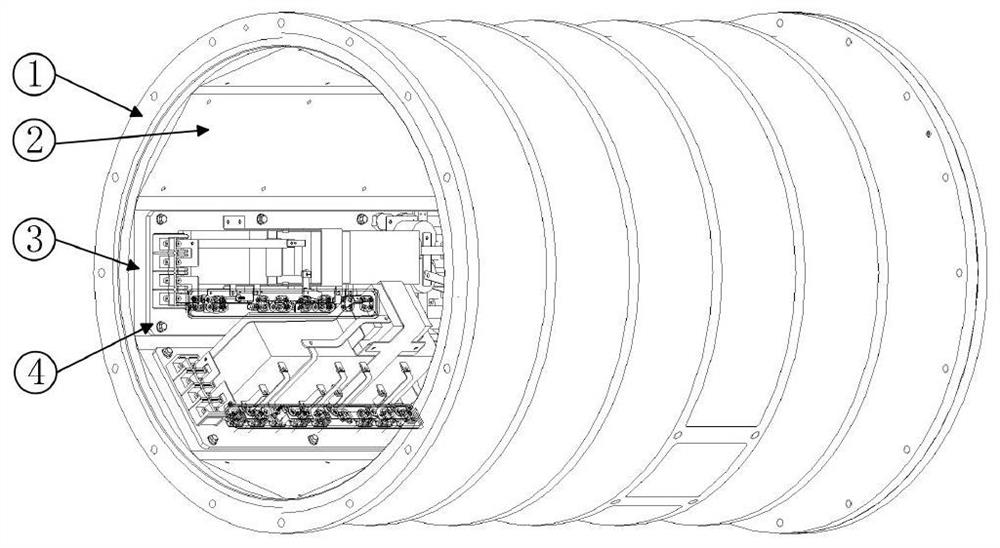

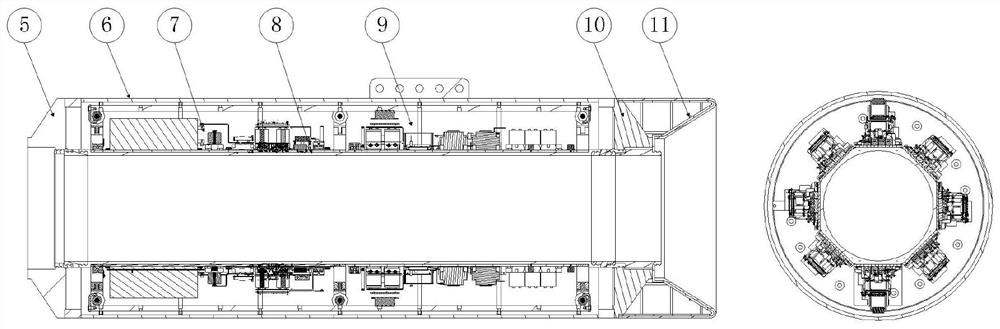

[0026] The present invention provides a double-layer contact heat conduction high-power power supply pressure-bearing housing for large water depths, which includes a rear sealing cover 5, an outer metal housing 6, an inner composite housing 8, a front sealing cover 10, and a rubber guide Cover 11.

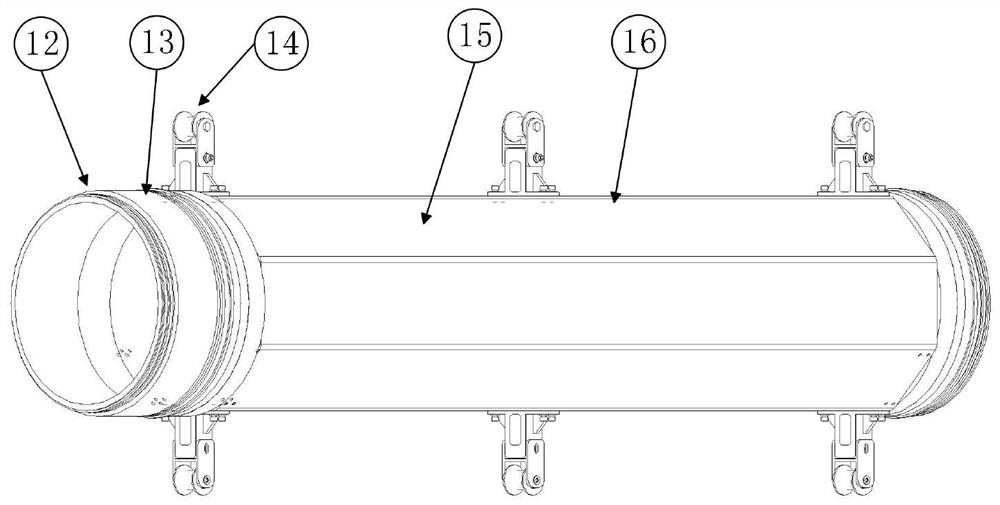

[0027] Wherein the outer metal shell 6 includes a circular shell 17, a ring rib 18 and a guide rail 19, wherein the outer metal shell 6 includes a plurality of ring ribs 18, and the ring rib 18 includes a mounting groove surface and a threaded hole; the guide rail 19 has two , the mounting surface of the guide rail 19 is assembled with the mounting groove surface of the ring rib 18; the ring rib 18 and the circular shell 17 are welded and positioned. The installation process is: first install the ring rib 18 and the two guide rails 19 (through the process to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap