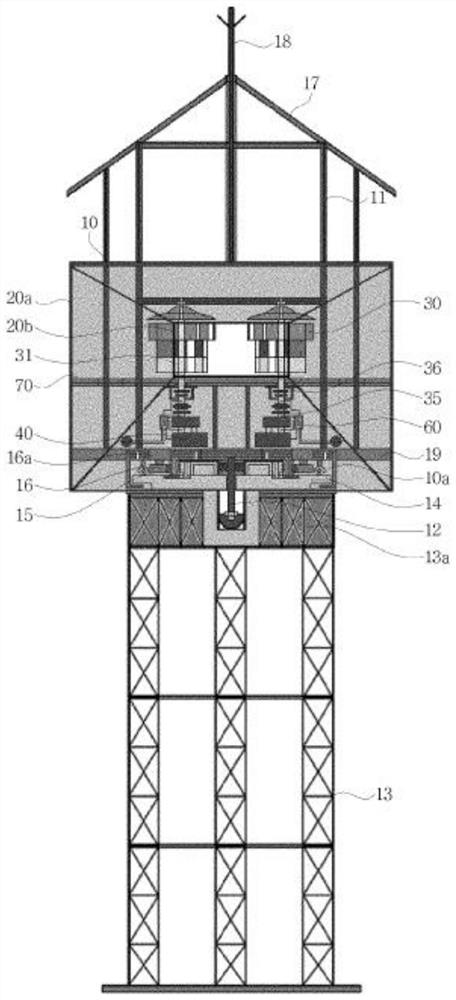

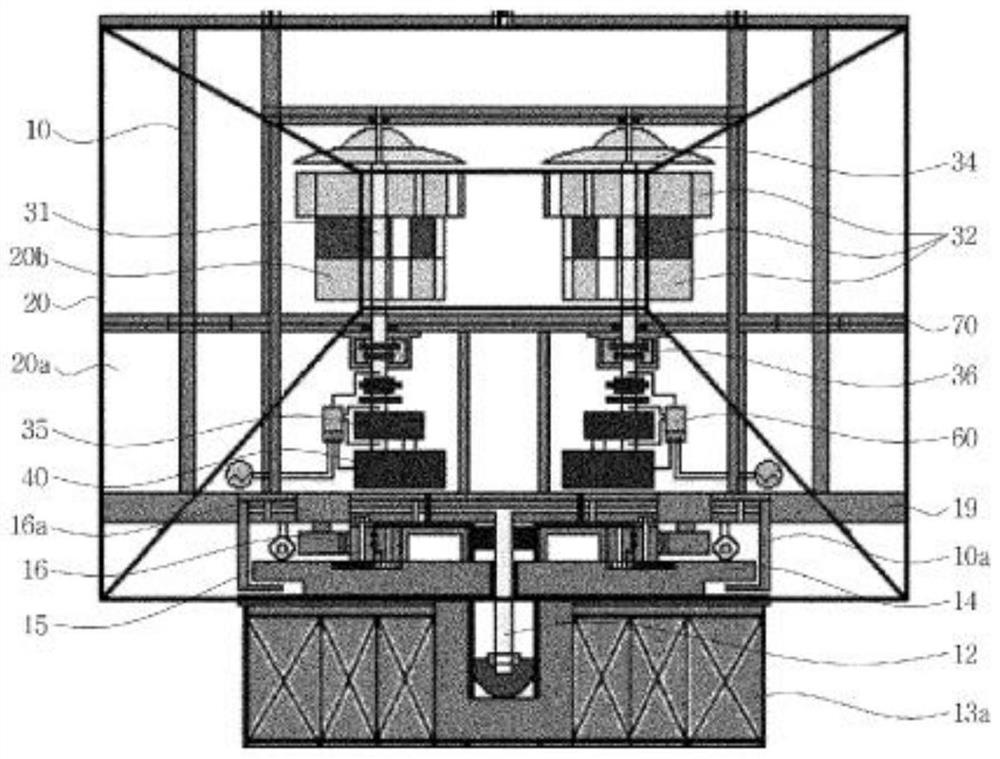

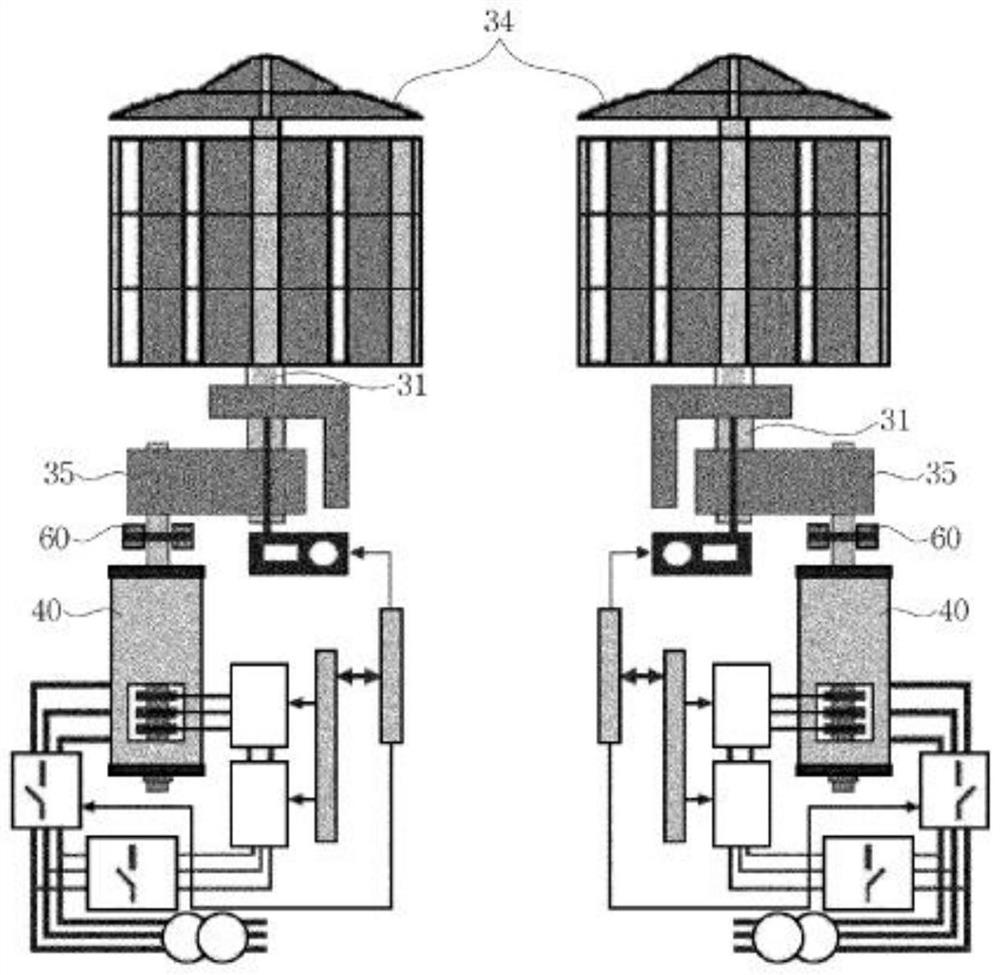

Hybrid power generation system

A hybrid power generation and generator technology, which is applied in electrical signal transmission systems, wind power generation, photovoltaic power generation, etc., can solve the problems of reduced rotation speed, increased power generation, and increased rotational force, so as to achieve increased rotational torque and power generation. Effects of improved energy efficiency and increased rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific viewpoints and specific technical features of the present invention will become more clear based on the following specific contents and embodiments related to the accompanying drawings. It should be noted that, when assigning reference numerals to components in the drawings in this specification, the same components are given the same reference numerals as much as possible even though they are shown in different drawings. In addition, when explaining one embodiment of the present invention, the detailed description is omitted when it is judged that a specific description of a related well-known configuration or function may obscure the gist of the present invention.

[0053] In addition, terms such as first, second, A, B, (a), and (b) may be used when describing components of the present invention. These terms are used only to distinguish the constituent elements from other constituent elements, and do not limit the nature, order, sequence, etc. of the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com