Manufacturing method of thin-wall radio frequency superconducting cavity

A technology of radio frequency superconducting cavity and manufacturing method, which is applied in accelerators, electrical components, etc., can solve the problems of high quench risk at low temperature and low thermal conductivity, so as to reduce the risk of quench at low temperature, improve heat conduction effect, and reduce flow effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solutions in the present application, the technical solutions in the present application will be described in conjunction with the drawings.

[0024] The core of this application is to provide a method of manufacturing a thin-walled radio supercoder, which can solve the problem of low thermal conductivity and low risk of thermal conductivity and low temperature loss.

[0025] A method of manufacturing a thin-walled radio frequency supercoding cavity, which includes the following steps:

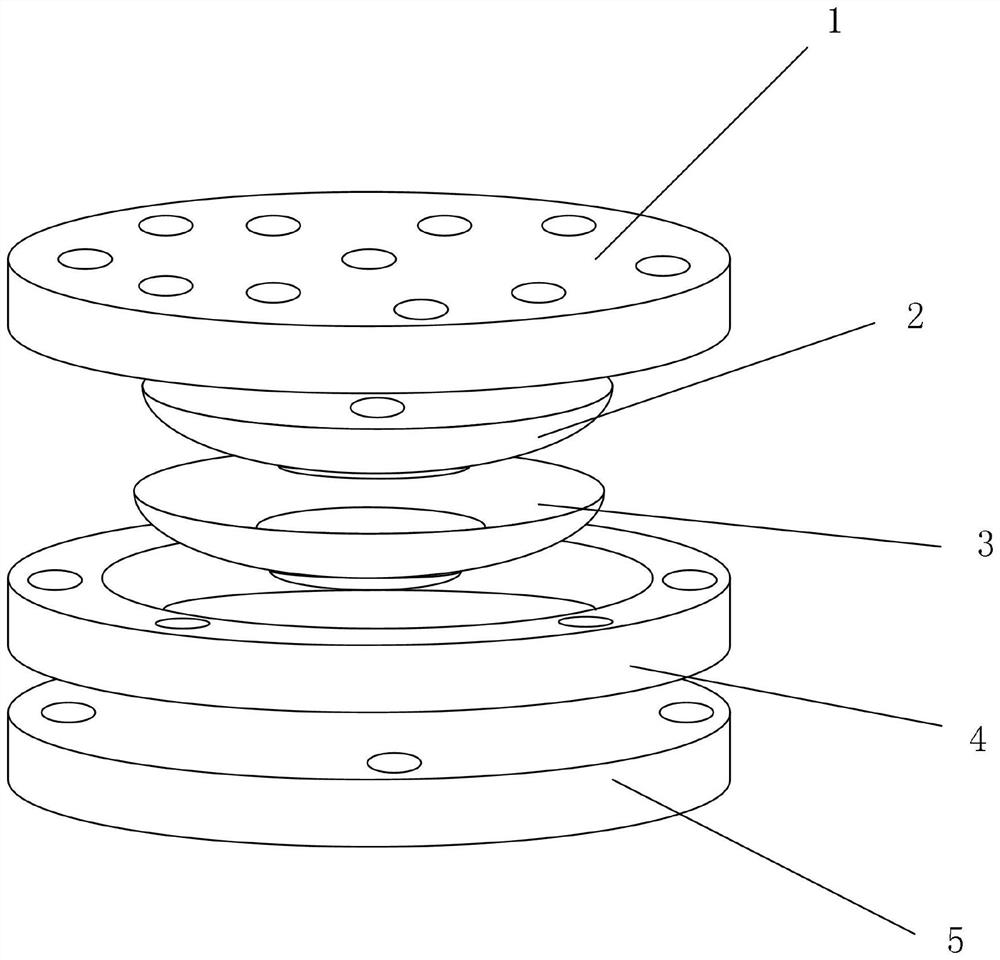

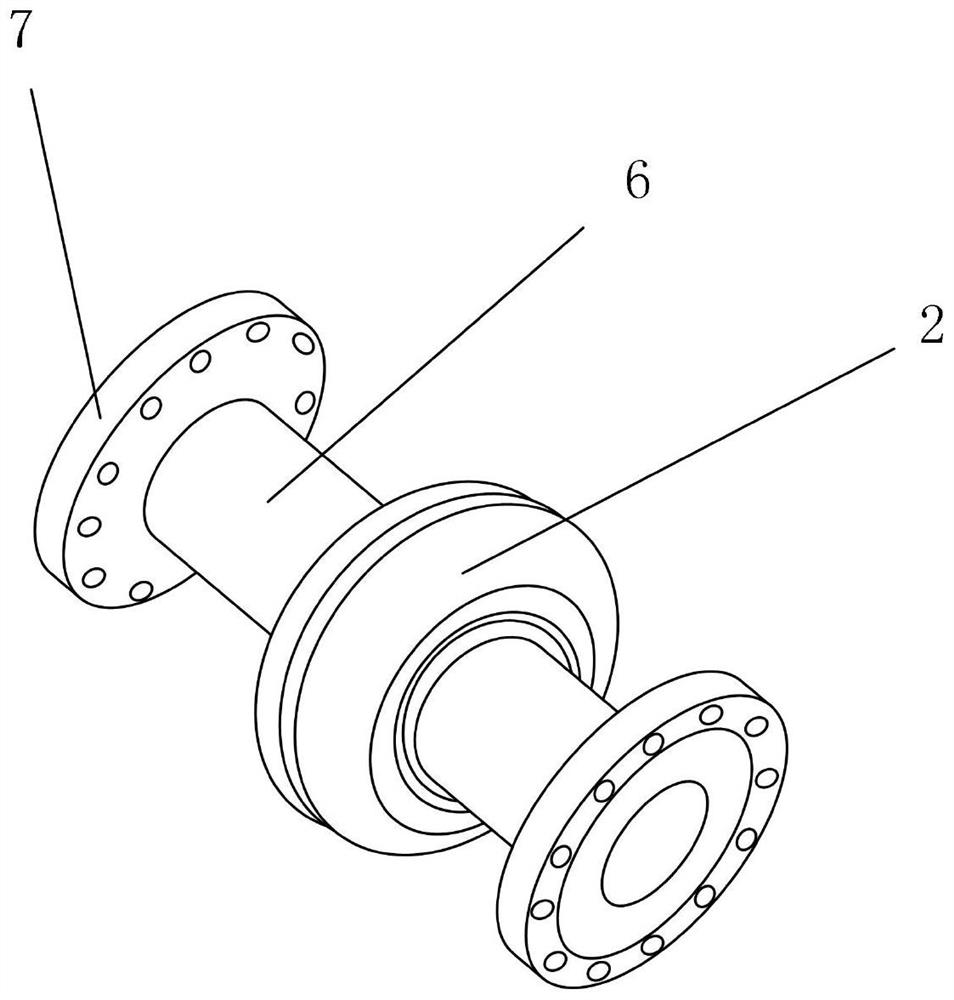

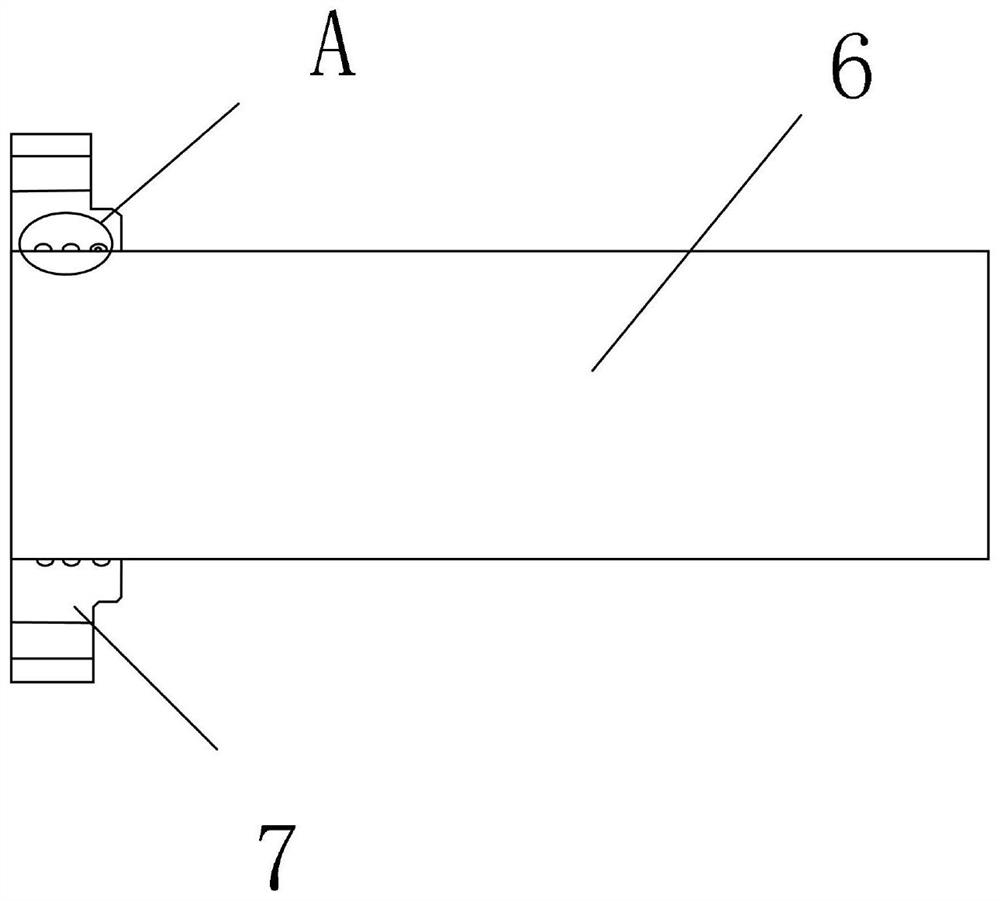

[0026] S1: The lower material is 275mm, the thickness of 1 mm is 1 mm, an annealing state, and the naked eye is observed, and the defects are selected without the deficiencies, and the oil is applied tweak over the bony plate, and in the punching mold, the lower pressure plate is mounted at the bottom of the punching mold. The upper platen is mounted on the upper surface of the bismuth plate, wherein the punching mold includes a convex film locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com