Anti-ultraviolet radiation medium-wave infrared transmitting glass as well as preparation method and application thereof

An infrared glass, anti-ultraviolet technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools and other directions, can solve the problems of steep absorption edge, low light transmittance, etc., and achieves simple preparation method, simple operation, good thermal stability performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

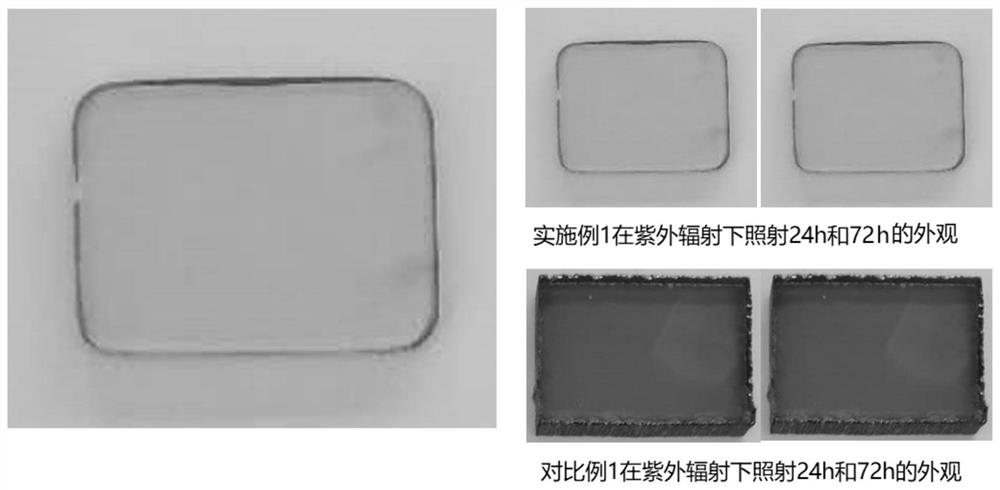

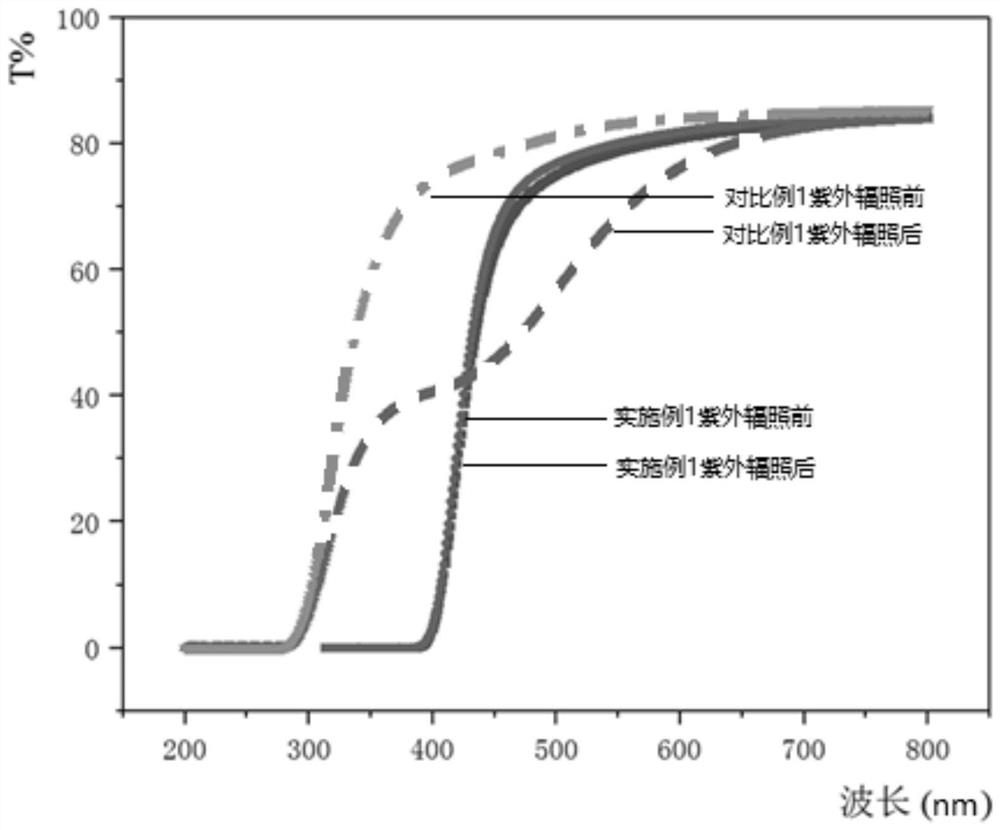

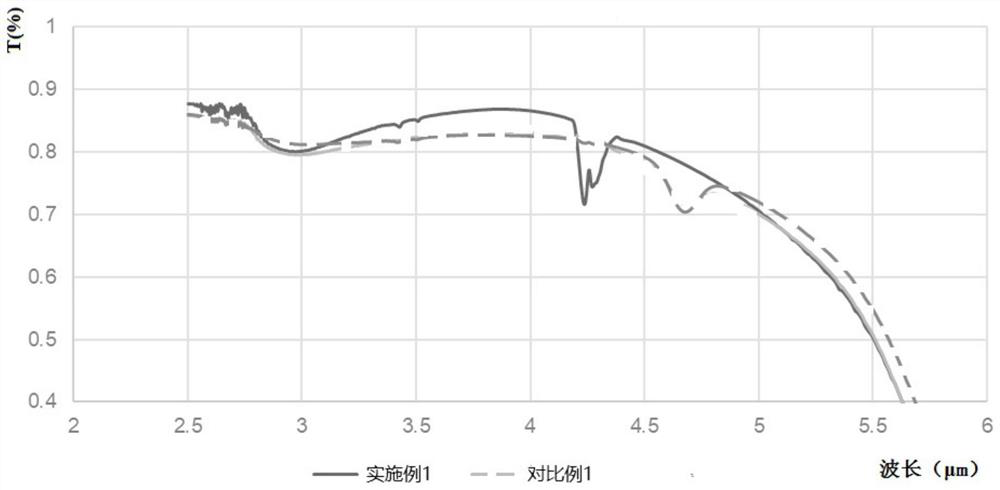

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing an anti-ultraviolet radiation transparent mid-wave infrared glass, comprising the following steps:

[0046] (1) raw material preparation: according to the mass fraction of glass composition, calculate the quality of corresponding each composition, weigh raw material; The specific composition and ratio of described raw material are as follows: BaO 2 11~23%; Ga 2 o 3 35-58%; CaO 2 20-43%; Y 2 o 3 10-26%; CeO 2 0.3-2.0%; if it is higher or lower than this range, it will cause defects such as glass crystallization, devitrification, reduced infrared transmission ability, and lack of anti-ultraviolet ability.

[0047] (2) Preparation: Grind all raw material components uniformly to form a mixture, put it into a platinum crucible, and place it in a silicon carbide rod electric furnace at 1100-1300 ° C for more than 8 hours, and obtain a uniform and free Glass liquid with bubbles; if the melting time is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com