Method for preparing Ni-Ti3C2 composite electrocatalyst by hydrothermal method

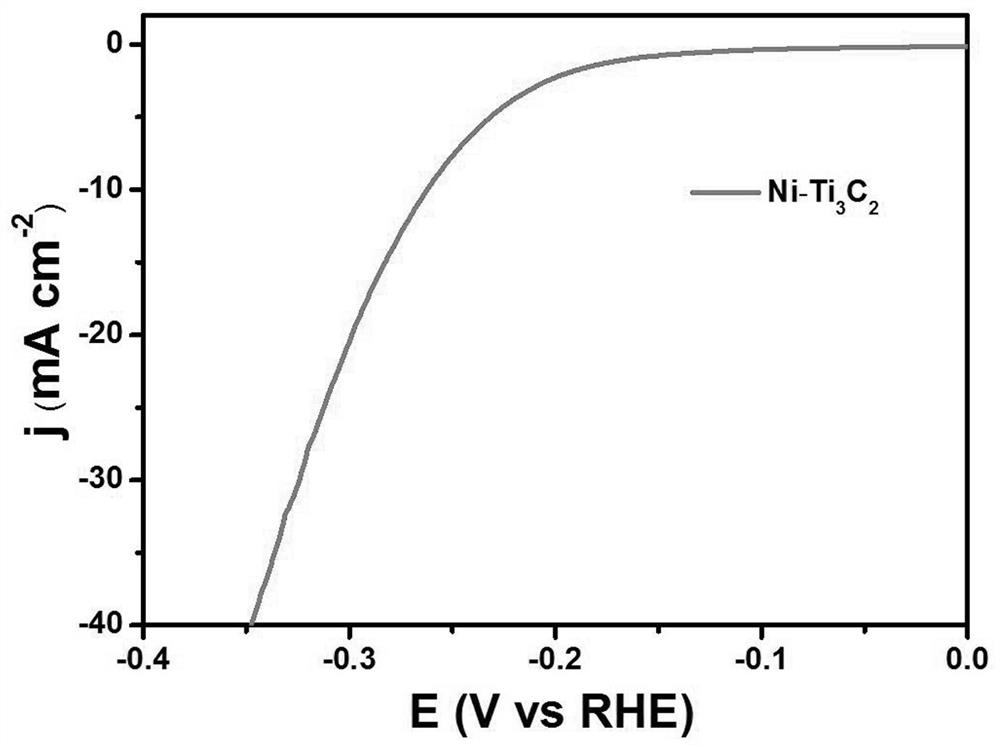

A technology of electrocatalyst and hydrothermal method, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor oxidation resistance, surface catalytic activity and loss of electronic characteristics, etc., to achieve increased contact area, excellent catalytic hydrogen evolution performance, The effect of fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

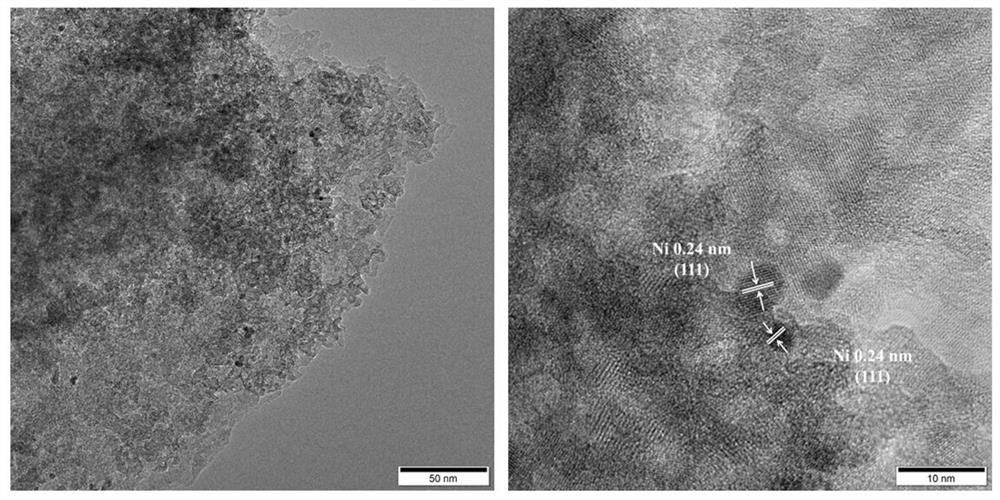

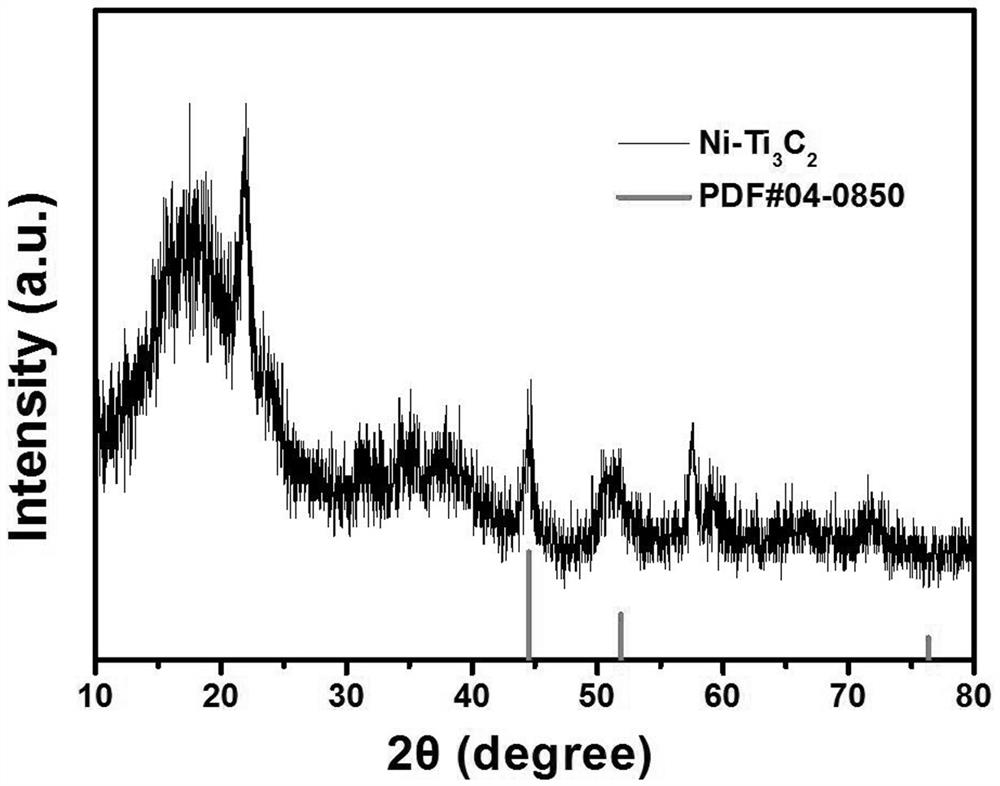

[0027] Preparation of Ni-Ti by a hydrothermal method 3 C 2 The method for composite electrocatalyst, concrete steps are as follows:

[0028] 1. Take 20 mg Ti 3 C 2 The nanosheets were dispersed into 20 mL of water, and the first homogeneous mixed solution was obtained by ultrasonic treatment; among them, Ti 3 C 2 by Ti 3 AlC 2 The powder was treated with 9 M hydrochloric acid at 35 °C for 48 h, then washed with deionized water to pH 6, and then sonicated at 300 W for 2 h.

[0029] 2. Disperse 237.9 mg of nickel chloride hexahydrate into 10 mL of water, and perform ultrasonic treatment to obtain a uniform second mixed solution;

[0030] 3. Take 176 mg of ascorbic acid and disperse it in 10 mL of water, and perform ultrasonic treatment to obtain a uniform third mixed solution;

[0031] 4. Transfer the first mixed solution to a 100 ml high-temperature and high-pressure reactor. The inner wall of the high-temperature and high-pressure reactor is equipped with a polytetrafl...

Embodiment 2

[0042] Preparation of Ni-Ti by a hydrothermal method 3 C 2 The method for composite electrocatalyst, concrete steps are as follows:

[0043] 1. Take 20 mg Ti 3 C 2 The nanosheets were dispersed into 50 mL of water, and the first mixed solution was obtained by ultrasonic treatment; among them, Ti 3 C 2 by Ti 3 AlC 2 The powder was treated with 9 M hydrochloric acid at 35 °C for 48 h, then washed with deionized water to pH 6, and then sonicated at 300 W for 2 h.

[0044] 2. Disperse 237.9 mg of nickel chloride hexahydrate into 30 mL of water, and perform ultrasonic treatment to obtain a uniform second mixed solution;

[0045] 3. Take 176 mg of ascorbic acid and disperse it into 30 mL of water, and perform ultrasonic treatment to obtain a uniform third mixed solution;

[0046] 4. Transfer the first mixed solution to a 100 ml high-temperature and high-pressure reactor. The inner wall of the high-temperature and high-pressure reactor is equipped with a polytetrafluoroethyle...

Embodiment 3

[0052] Preparation of Ni-Ti by a hydrothermal method 3 C 2 The method for composite electrocatalyst, concrete steps are as follows:

[0053] 1. Take 20 mg Ti 3 C 2 The nanosheets were dispersed into 30 mL of water, and the first mixed solution was obtained by ultrasonic treatment; among them, Ti 3 C 2 by Ti 3 AlC 2 The powder was treated with 9 M hydrochloric acid at 35 °C for 48 h, then washed with deionized water to pH 6, and then sonicated at 300 W for 2 h.

[0054] 2. Disperse 237.9 mg of nickel chloride hexahydrate into 20 mL of water, and perform ultrasonic treatment to obtain a uniform second mixed solution;

[0055] 3. Take 176 mg of ascorbic acid and disperse it into 20 mL of water, and perform ultrasonic treatment to obtain a uniform third mixed solution;

[0056] 4. Transfer the first mixed solution to a 100 ml high-temperature and high-pressure reactor. The inner wall of the high-temperature and high-pressure reactor is equipped with a polytetrafluoroethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com