Method for reducing weight of titanium alloy workpiece

A titanium alloy and workpiece technology, applied in the field of titanium alloy workpiece weight reduction, can solve the problems of high cost, poor precision, low efficiency, etc., and achieve the effects of high weight reduction efficiency, low time and labor costs, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

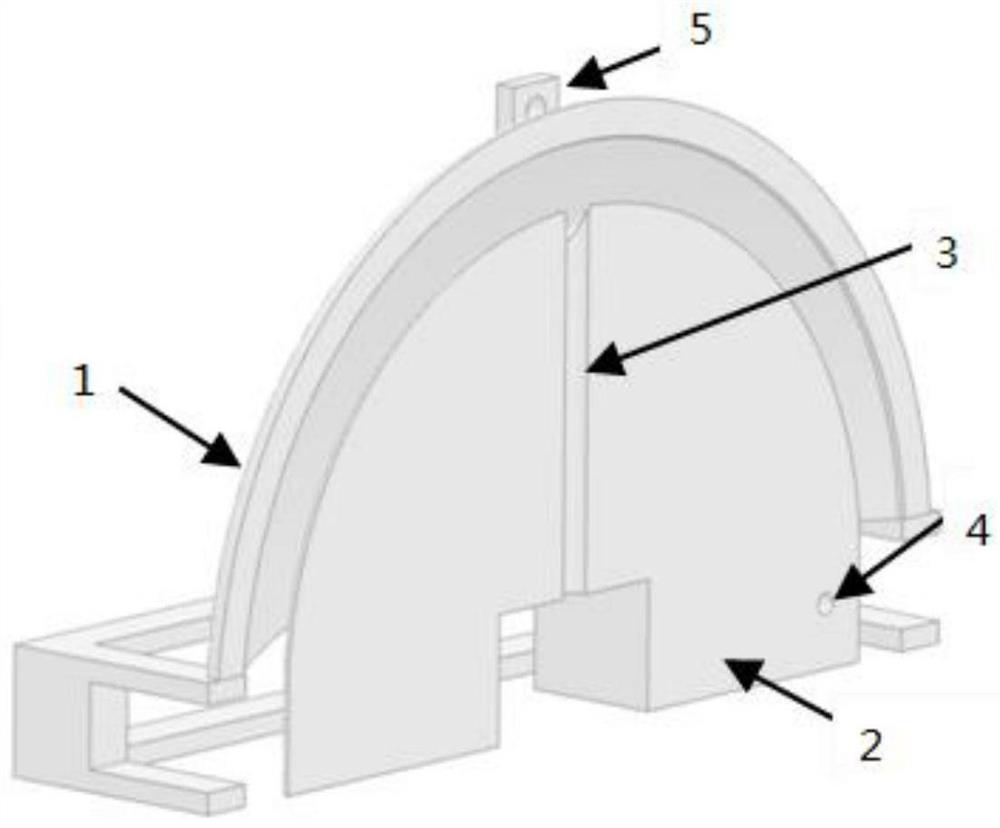

[0048] According to a preferred embodiment of the present invention, the graphite electrode is provided with a pump body connection through hole and an installation hole, the liquid diffusion pump communicates with the pump body connection through hole, and the installation hole is connected with a cathode wire.

[0049] In the present invention, the setting of the through hole and the realization of the diffusion process can promote ion migration. There is no special limitation on the size of the pump body connection through hole, which can be a conventional choice in the field. Preferably, the pump body connection through hole The diameter of the hole is 20-40mm.

[0050] Exemplarily, as Figure 3-5 As shown, the graphite electrode 2 is provided with a through hole 3 that penetrates from bottom to top; in order to facilitate liquid diffusion, the pump communicates with the through hole 3, preferably, a gap is set below the graphite electrode 2 with the through hole 3 as the ...

Embodiment 1

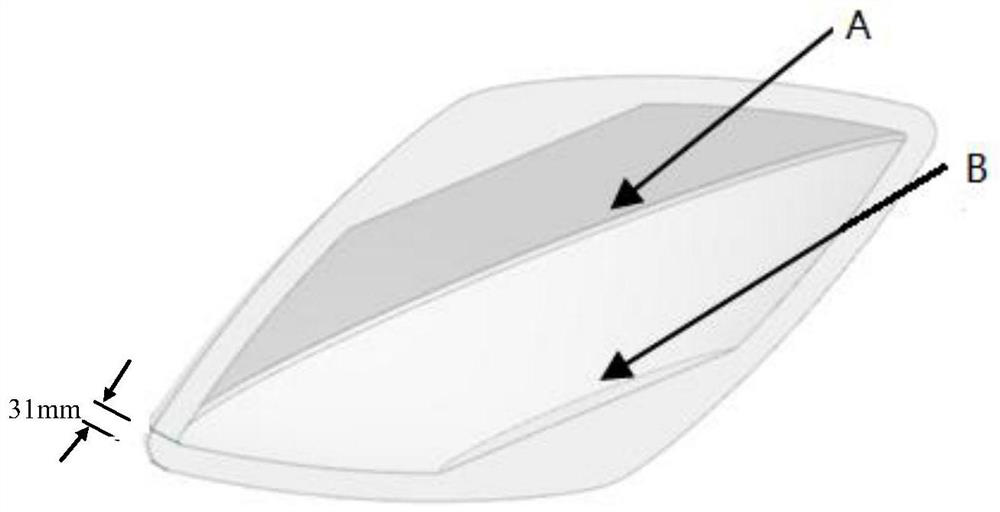

[0058] (1) Use a hand-held three-dimensional scanner to scan the workpiece at 360°, complete the three-dimensional reconstruction of the workpiece through the scanner equipment, and compare the scanning results with the theoretical model of the workpiece. According to the comparison results, the margin of the weight reduction position is required The upper limit is 5.5mm, the lower limit is 4.8mm, and 4.8mm is used as a reference.

[0059] (2) Insulating glue is applied to parts of titanium alloy complex workpieces that do not require weight reduction;

[0060] (3) Connect the installation hole of the graphite electrode with the cathode wire of the DC power supply, and connect the weight-reducing part of the titanium alloy complex workpiece with the anode wire of the DC power supply. The shape of the graphite electrode is consistent with the shape of the weight-reducing part of the titanium alloy complex workpiece. Matching, connect the through hole (diameter of 30mm) of the p...

Embodiment 2

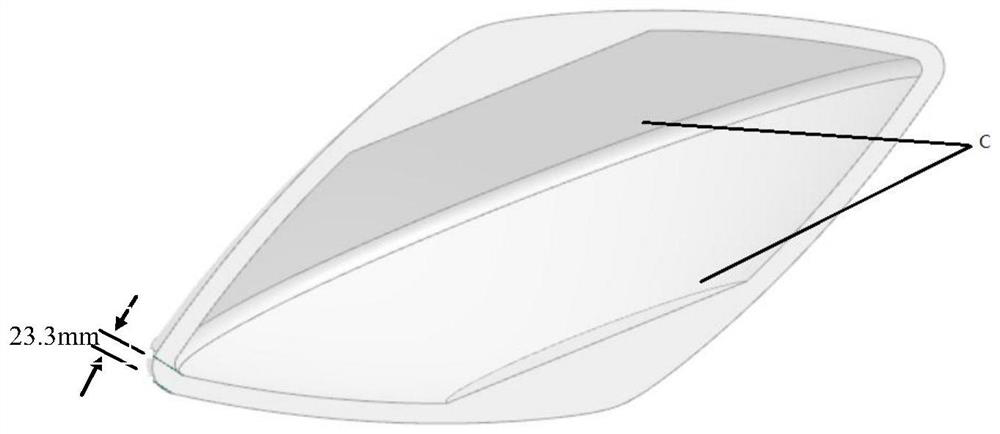

[0064] (1) Use a hand-held three-dimensional scanner to scan the workpiece at 360°, complete the three-dimensional reconstruction of the workpiece through the scanner equipment, and compare the scanning results with the theoretical model of the workpiece. According to the comparison results, the margin of the weight reduction position is required The upper limit is 3.5mm, the lower limit is 3mm, and 3mm is used as a reference.

[0065] (2) Insulating glue is applied to parts of titanium alloy complex workpieces that do not require weight reduction;

[0066] (3) Connect the installation hole of the graphite electrode with the cathode wire of the DC power supply, and connect the weight-reducing part of the titanium alloy complex workpiece with the anode wire of the DC power supply. The shape of the graphite electrode is consistent with the shape of the weight-reducing part of the titanium alloy complex workpiece. Matching, connect the through hole (25mm in diameter) of the pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com