Ordered mesoporous high-entropy metal oxide and preparation method thereof

An oxide and high-entropy technology, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of insufficient exposure of active sites of surfactants to effectively assemble high-entropy oxides, difficulty in metal precursors, etc. Achieve the effects of adjustable mesoscopic structure, strong controllability, and adjustable specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Mix 1.5g F127 (nonionic surfactant, polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mw=16800), 30mL tetrahydrofuran and 4.0mL concentrated hydrochloric acid (36-38wt %) and 4.0mL acetic acid, stirred at room temperature for 30 minutes to obtain a clear and transparent mixed solution, then added 0.40g aluminum isopropoxide, 0.48g tetrabutyl titanate, 0.74g niobium ethoxide, 0.65g molybdenum acetylacetonate Continue to stir with 0.96g zirconium n-butoxide for one hour; drip the mixed solution on the evaporating dish, then transfer it to a constant temperature drying oven, and place it at 80°C for 48h; The surfactant was removed by calcination at 700°C for 3 hours, and the heating rate was 1°C / min to obtain ordered mesoporous high-entropy metal oxide (AlNbMoTiZrO).

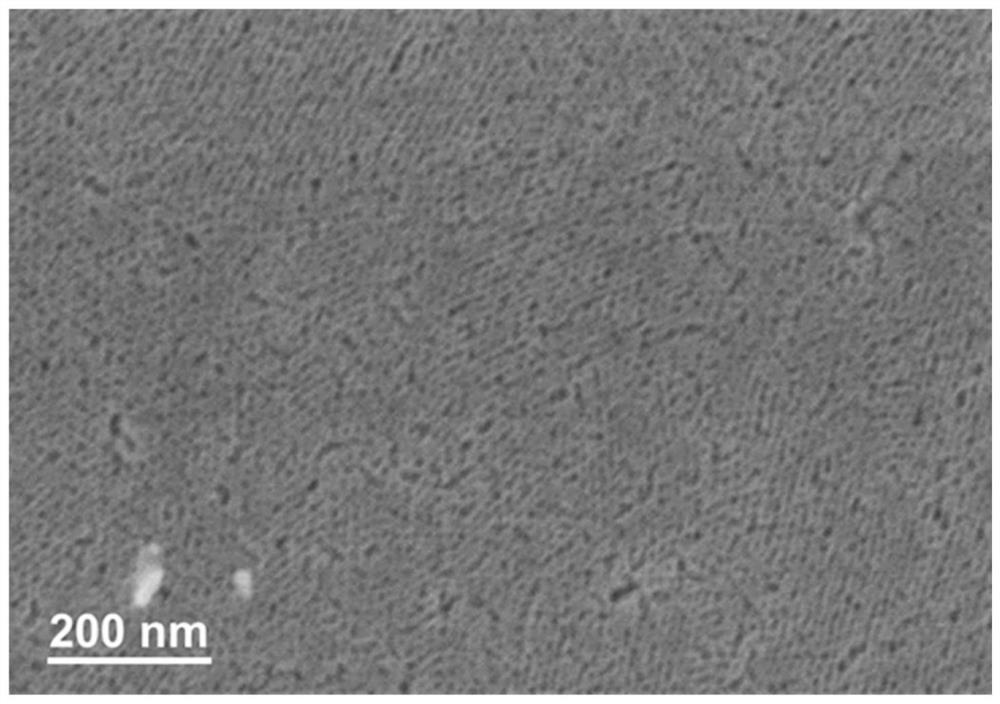

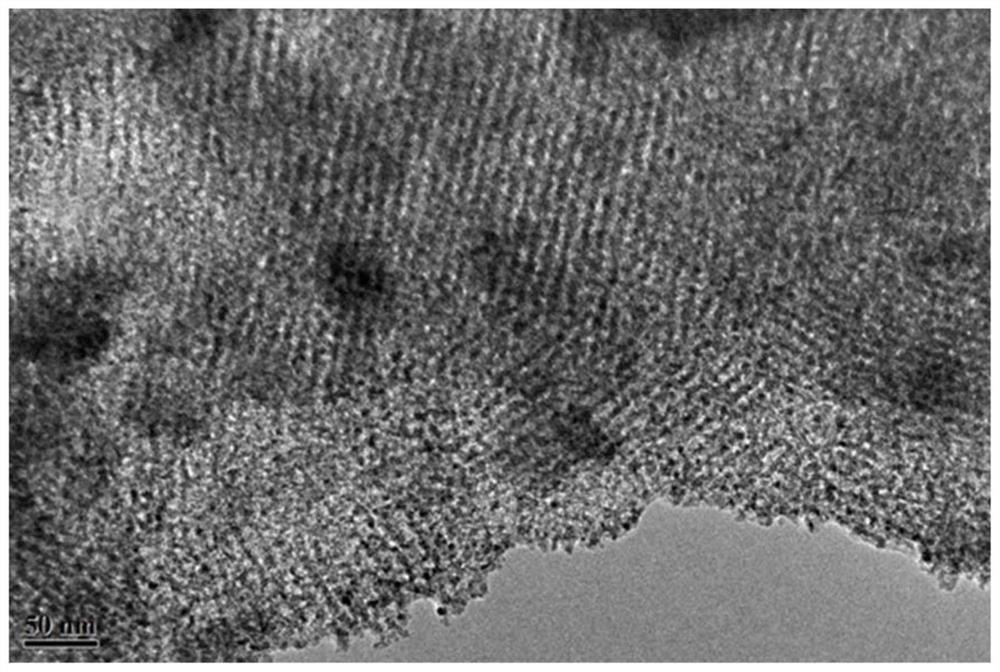

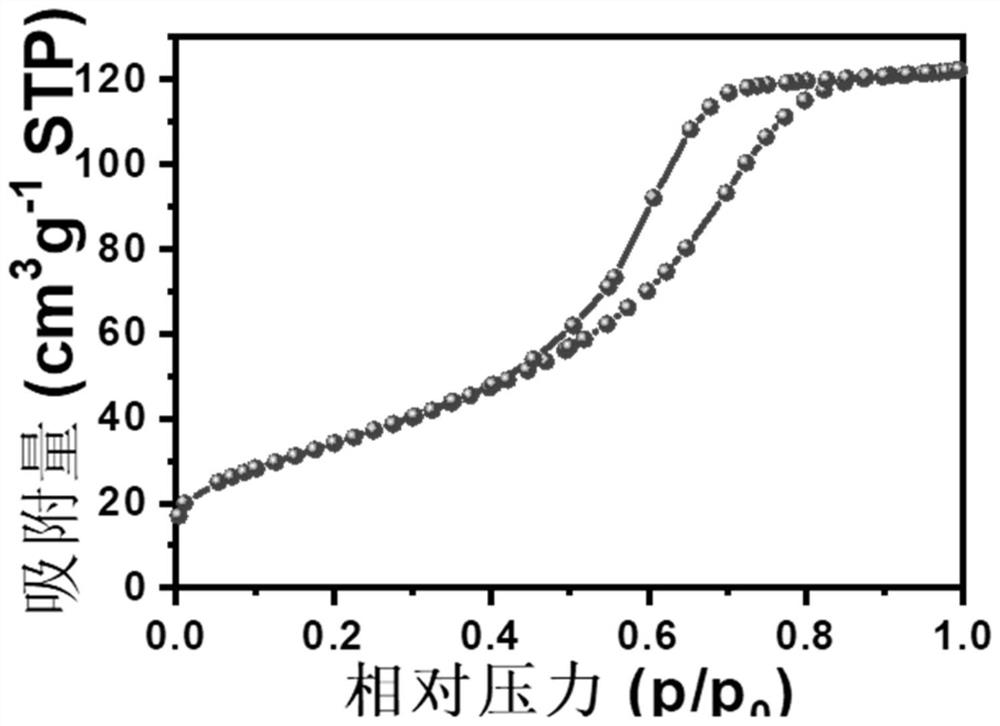

[0051] Specifically, see Figure 1-2 , figure 1 The scanning electron microscope image shows that the ordered mesoporous high-entropy metal oxide (AlNbMoTiZrO) obtained in Examp...

Embodiment 2

[0055] Compared with Example 1, most of them are the same, except that in this example, F127 is changed to equimolar N-acyl glutamate.

Embodiment 3

[0057] Compared with Example 1, most of them are the same, except that in this example, F127 is changed to equimolar sodium N-dodecylalanine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com