Sulfated polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion and polyacrylate, which is applied in the preparation of sulfated polyacrylate emulsion materials and the preparation of sulfated polyacrylate emulsions, can solve the problems affecting the separation and analysis effect of liquid chromatography medium and the particle size. Diameter size and pore size structure cannot be accurately controlled, particle size and pore size are not uniform, etc., to achieve the effect of easy continuous operation, uniform and stable emulsion, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

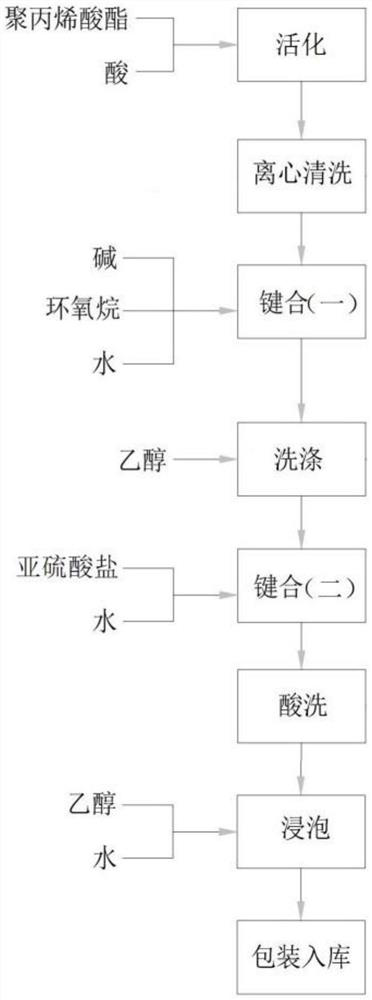

[0030] The invention provides a kind of preparation method of sulfated polyacrylate emulsion, comprises following main steps:

[0031] S1 polyacrylate activation treatment, the pre-prepared polyacrylate-based balls with fixed components, particle size and pore size are subjected to acidic activation treatment to obtain activated polyacrylate microspheres; the particle size of the polyacrylate-based balls 15μm~90μm and the pore size is The acidic activation treatment uses concentrated sulfuric acid to prepare a 0.4M-0.6M concentrated sulfuric acid solution, and the polyacrylate-based balls are added to the concentrated sulfuric acid solution and stirred evenly to activate the polyacrylate-based balls. The stirring speed is 250rpm-350rpm, and the activation time is 60min~120min;

[0032] S2 The first bonding reaction, the activated polyacrylate microspheres are dispersed in the alkaline solution, and the alkylene oxide solution is added to carry out the first bonding reaction,...

Embodiment 1

[0050] The preparation method of a kind of sulfated polyacrylate emulsion provided in this embodiment, firstly, adopts polyglycidyl methacrylate-polyethylene glycol dimethacrylate copolymer base sphere prepared in advance, the copolymerized polyacrylic acid The particle size of ester-based balls is 45 μm ~ 60 μm and the pore size is Use concentrated sulfuric acid to prepare 0.5M concentrated sulfuric acid solution for acidic activation treatment, and add copolymerized polyacrylate base balls to the concentrated sulfuric acid solution and stir evenly to activate the base balls. The stirring speed is 280rpm, and the activation time is 100min to obtain activated polyacrylate. Copolymerized microspheres;

[0051] Secondly, carry out the bonding reaction for the first time to obtain the activated polyacrylate copolymerized microspheres, the copolymerized microspheres are dispersed in 30% NaOH alkaline solution, and add the epichlorohydrin solution of concentration 3.0%, at reactio...

Embodiment 2

[0058] The preparation method of a kind of sulfated polyacrylate emulsion provided in this embodiment, firstly, adopt the pre-prepared polyglycidyl methacrylate base ball, the particle diameter of the polyacrylate base ball is 15 μm~25 μm and the pore diameter is Use concentrated sulfuric acid to prepare 0.45M concentrated sulfuric acid solution for acidic activation treatment, and add polyacrylate base balls to the concentrated sulfuric acid solution and stir to activate the base balls. The stirring speed is 300rpm, and the activation time is 80min to obtain activated polyacrylate microspheres. ball;

[0059] Secondly, carry out the first bonding reaction to the obtained activated polyacrylate microspheres, disperse the microspheres in a 32% KOH alkaline solution, and add a 4.0% epichlorohydrin solution at a reaction temperature of 60°C , the reaction pressure is 0.12MPa, the reaction time is 20h for the first bonding reaction, the pH value is maintained at about 9.3, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com