Impact-resistant multiplication combined type coking waste water treatment process

A technology for coking wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. , the aeration tank foam is difficult to eliminate and other problems, to achieve the effect of improving biodegradability and optimizing material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

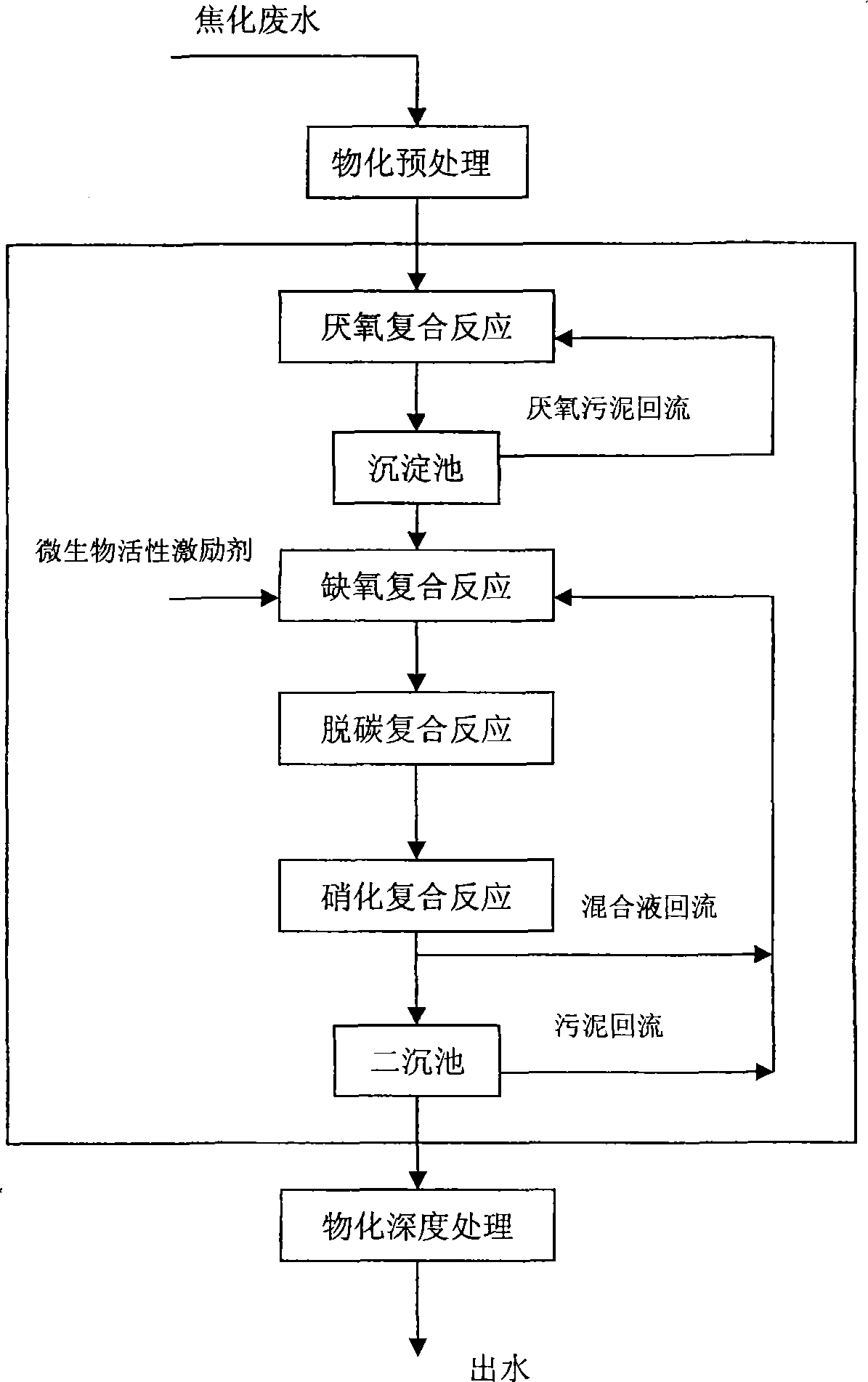

[0029] see figure 1 , The technique of the present invention does not add any dilution water. The volume of coking wastewater in a coking plant is 1500m 3 / d. The sources of waste water are: a. Ammonia distillation waste water with a water volume of 30m 3 / h; b. Drainage of tar workshop, water volume 10-60m 3 / h; c. Drainage of refined benzene workshop, water volume 10m 3 / h; d, cleaning the drainage of the tanker e, underground phenolic water. The physical and chemical pretreatment technology adopts stepless variable speed mechanical stirring coagulation reaction and pressure dissolved air flotation technology. The diameter of microbubbles generated by the pressure dissolved air release system is about 20 μm, and the coagulant dosage concentration is 50-200mg / L.

[0030] Anaerobic compound reaction

[0031] Polyethylene spherical packing is suspended in the reactor, mixed by mechanical stirring, the hydraulic retention time is 8h, the biofilm microbial concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com