Deep processing method of titanium slag

A technology of deep processing and titanium slag, applied in the field of comprehensive recovery of coal-based direct reduction, can solve the problems of poor selectability, high production cost, and many impurities, and achieve improved crystallization degree, high added value of products, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Before the vanadium-titanium magnetite electric furnace smelts the slag, the temperature of the titanium-containing electric furnace slag is raised to 1750°C, and the temperature is kept for 10 minutes. The thermal insulation device can be a slag bag with a thermal insulation layer, and the thermal insulation slag bag can be provided with a layer of refractory and heat insulating bricks. After the titanium-containing electric furnace slag is naturally cooled to 1100°C in the thermal insulation device, the electric furnace Separation of crystal growth device, natural cooling to room temperature, crushing, grinding to 45μm, flotation of titanium, titanium concentrate TiO 2 Grade 80.13%, TiO 2 The recovery rate was 72.36%.

Embodiment 2

[0034] Before the slag is smelted in the vanadium-titanium magnetite electric furnace, the temperature of the titanium-containing electric furnace slag is raised to 1700 ° C, kept for 15 minutes, the slag outlet is opened, and the slag is placed in the heat preservation device for the electric furnace slag heat preservation mineral growth, and the temperature is naturally lowered to After 1000°C, separate the electric furnace slag from the thermal insulation crystal growth device, water-cool to room temperature, crush, grind to 55μm, and float titanium and titanium concentrate TiO 2 Grade 77.69%, TiO 2 The recovery rate is 74.65%.

Embodiment 3

[0036] Before the slag is smelted in the vanadium-titanium magnetite electric furnace, the temperature of the titanium-containing electric furnace slag is raised to 1650°C, kept for 20 minutes, the slag outlet is opened, and the slag is put into the electric furnace slag heat preservation crystal growth device for electric furnace slag heat preservation mineral growth , after natural cooling to 1000°C, separate the electric furnace slag from the thermal insulation growth device, cool naturally to room temperature, crush and grind to 65 μm, and select titanium by flotation, titanium concentrate TiO 2 Grade 72.93%, TiO 2 The recovery rate is 76.29%.

PUM

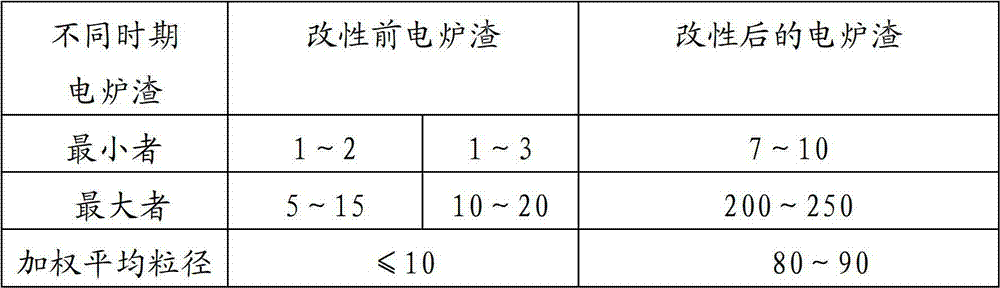

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com