Polyurethane solid electrolyte as well as preparation method and application thereof

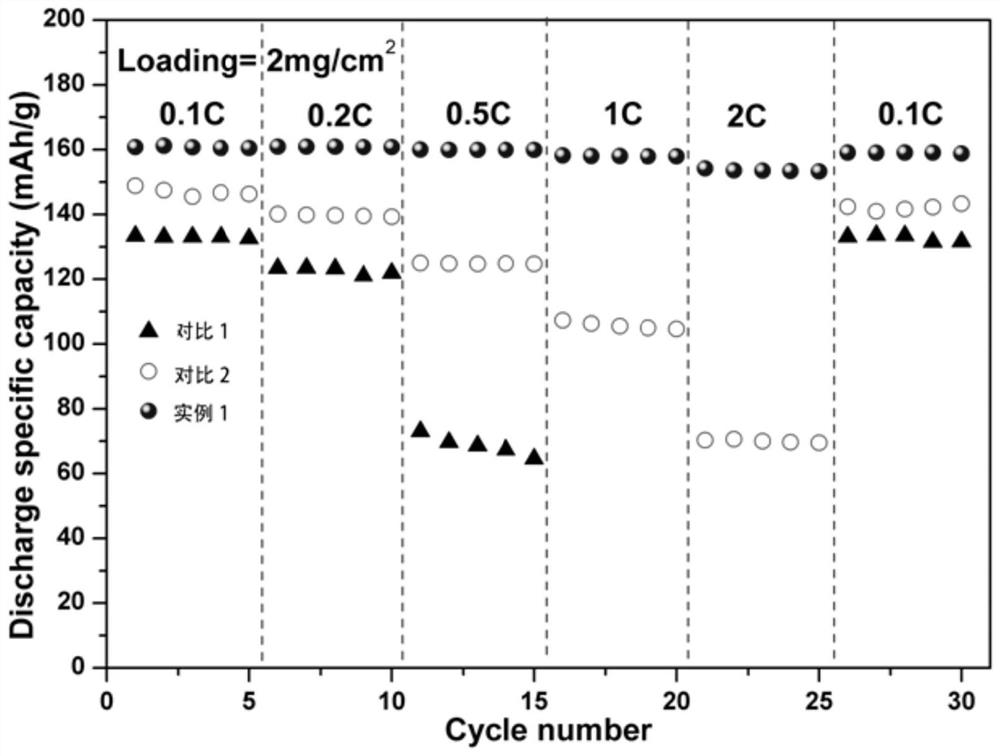

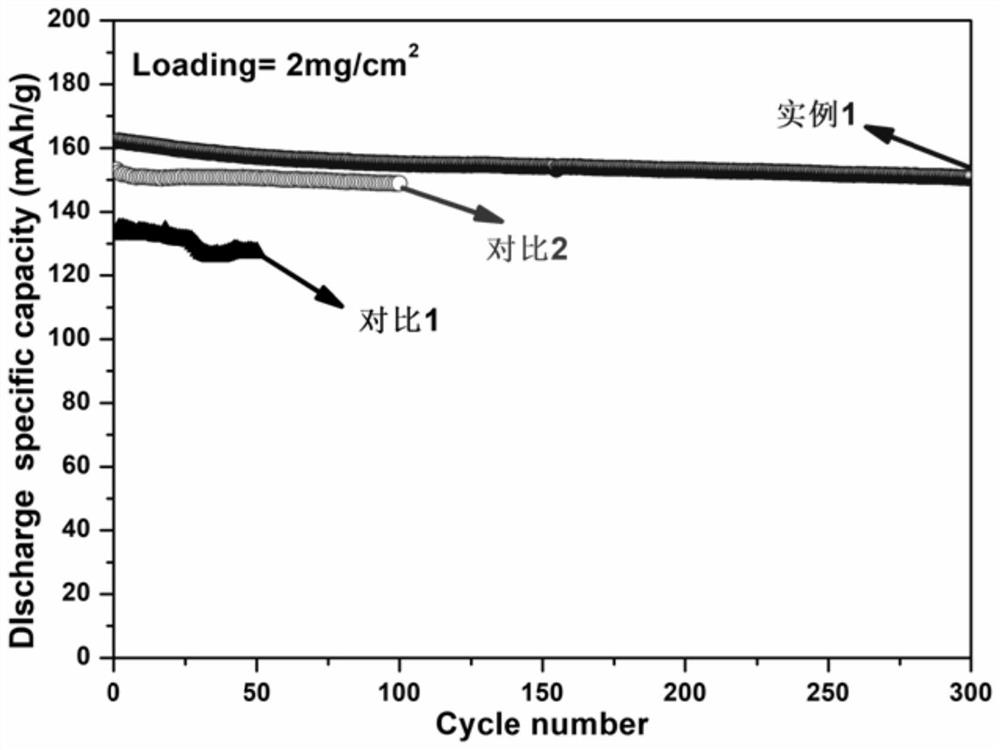

A solid electrolyte, polyurethane technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor lithium ion migration number and poor ion conductivity, and achieve high lithium ion migration number, high rate performance, easy to obtain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

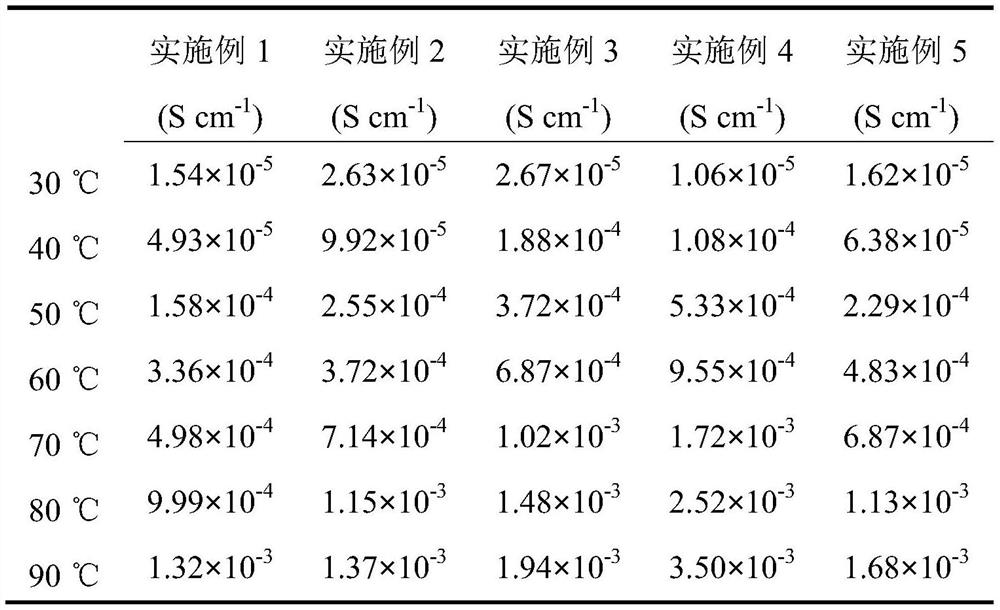

Embodiment 1

[0042] This embodiment provides a polyurethane solid electrolyte, which is prepared from the following weight of the following weight of the material: 60 parts of isocyanate, 300 copg, 5 catalysts, 18.5 parts of organometallic chromium MOF, chain extender I2, chain extender II8 parts, 500 solvents, 111 lithium salts. Among them, isocyanate is Chi-Timer; PPG molecular weight is 3000; organic chrome MOF is MIL-101 (CR), purchased from Suzhou Technology Nano Development Co., Ltd .; catalyst is dilasic titsalate; chain extender I Pyrrolidyl di amminopyrimidine oxide, chain extender II is MoCA; lithium salt is a litfsi: solvent is ethyl acetate.

[0043] The preparation method of the polyurethane solid electrolyte this embodiment includes the steps of:

[0044] (1) Under nitrogen protection, 60 parts of isocyanate, 300 PPG, 5 catalysts, 18.5 parts of organometallic MOF, 1 chain extender I2, chain extender II, 500 parts of solvent, 111 parts of lithium salt after mixing At 70 ° C, the r...

Embodiment 2

[0048] This embodiment provides a polyurethane solid electrolyte, which is prepared from the following weight of the material: 78 parts of isocyanate, 300 PPG, 5 catalysts, 20 organometallic MOF, chain extender I4, chain extender 16 parts, 540 solvents, 120 lithium salts. Among them, isocyanate is Chi-Timer; PPG molecular weight is 3000; organic chrome MOF is MIL-101 (CR), purchased from Suzhou Technology Nano Development Co., Ltd .; catalyst is dilasic titsalate; chain extender I Pyrrolidyl di amminopyrimidine oxide, chain extender II is MoCA; lithium salt is a litfsi: solvent is ethyl acetate.

[0049] The preparation method of the polyurethane solid electrolyte this embodiment includes the steps of:

[0050] (1) Under nitrogen protection, 78 of isocyanate, 300 PPG, 5 catalysts, organometallic MOF 20 parts, chain extender I4, 16 parts of the chain extender, 540 solvents, 120 parts of lithium salt, At 70 ° C, the reaction was reacted at 800 rpm of the ultrasonic dispersion for 30...

Embodiment 3

[0054] This embodiment provides a polyurethane solid electrolyte, which is prepared from the following weight of the raw material: 96 isocyanates, 300 copgs of PPG, 5 catalysts, 22 parts of organometallic MOF, chain extender I6 parts, chain extenders Type II24 parts, 580 parts of solvent, 128 lithium salts. Among them, isocyanate is Chi-Timer; PPG molecular weight is 3000; organic chrome MOF is MIL-101 (CR), purchased from Suzhou Technology Nano Development Co., Ltd .; catalyst is dilasic titsalate; chain extender I Pyrrolidyl di amminopyrimidine oxide, chain extender II is MoCA; lithium salt is a litfsi: solvent is ethyl acetate.

[0055] The preparation method of the polyurethane solid electrolyte this embodiment includes the steps of:

[0056] (1) Under nitrogen protection, 96 parts of isocyanate, 300 PPG, 5 catalysts, and organometallic chromium MOF22 parts, chain extender I6 parts, laulinant II24 parts, 580 parts of solvent, 120 parts of lithium salt, At 70 ° C, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com