One-component adhesive for thermoplastic polyurethane

A thermoplastic polyurethane and adhesive technology, used in polyether adhesives, graft polymer adhesives, non-polymer adhesive additives, etc., can solve the problem of difficult to achieve rubber tearing and bonding, no thermosetting part And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

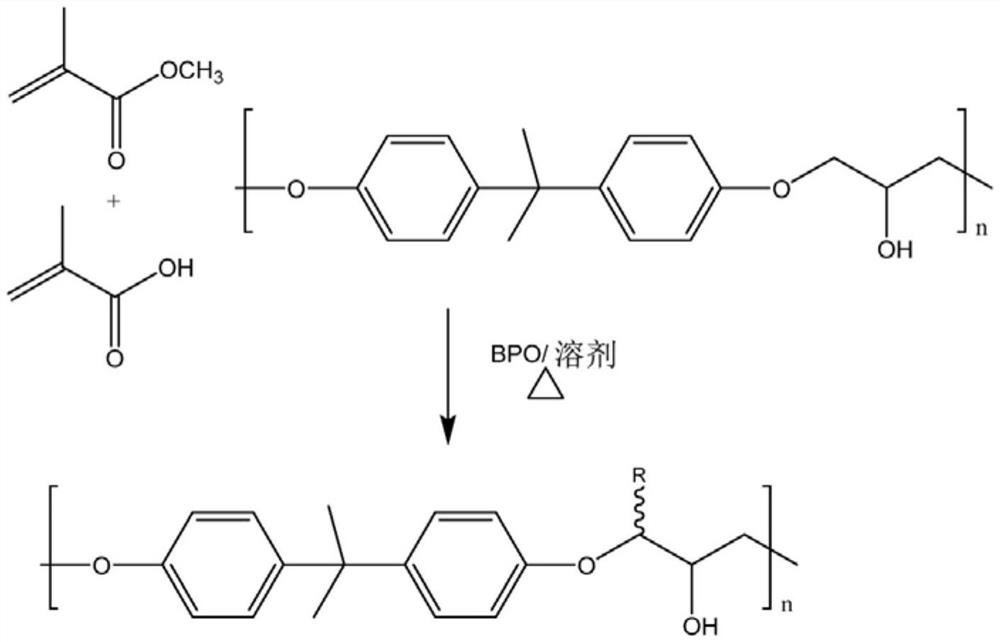

Method used

Image

Examples

Embodiment 1

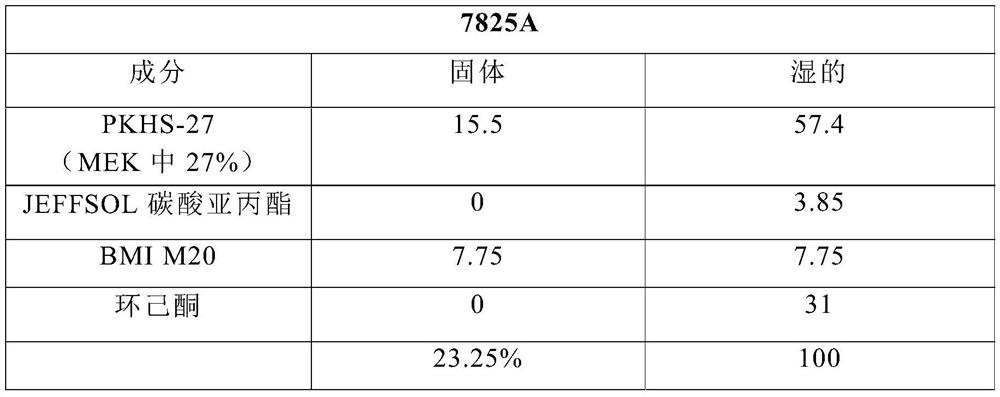

[0110] Three exemplary one-component adhesive composition (7825A, 71-1-8 and 17007-86D) preparation of the subject of the present disclosure provides formulations according to Table 1 below.

[0111] Table 1.TPU adhesive formulation

[0112]

[0113]

[0114]

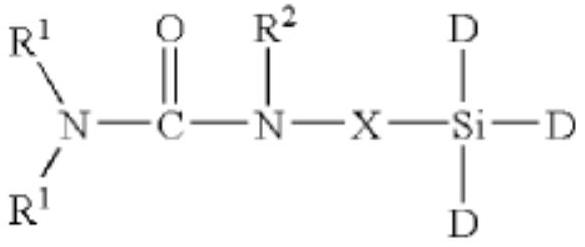

[0115] The binder formulation is modified phenoxy PKHS-27, commercially available from Gabriel PerformanceProducts, LLC (USA, Ohio, Akron), and in the form of 27% methyl ethyl ketone (MEK) solution of exist. Polymaleimide (M20) is a powder. Prior to addition to the adhesive composition, the M20 at 20% total solids content (TSC) was stirred into cyclohexanone, and heated with stirring to 80 deg.] C to 90 deg.] C for 20 minutes to 30 minutes. Being bound by any one theory, it is believed that, provided in the form of a solution M20 facilitate deposition and reactive (i.e., low temperature). Then PKHS-27, M20 and propylene carbonate was mixed. These compositions may be needed with a dye or colored pigment grinding / stai...

Embodiment 2

[0129] An additional exemplary single-component adhesive composition is prepared according to the formulation provided in Table 5 below. The composition was initially used with castable polyurethane, but it is now found that the composition is, for example, for about 30 minutes in combination of 121 ° C for about 30 minutes, is suitable for a series of TPUs.

[0130] As described in the above-mentioned embodiment, the modified phenoxy group of the above-mentioned adhesive formulation is PKHS-27, which is available from Gabriel Performance Products, LLC (USA, Ohio, Aklen), and 27% dissolved in methyl ethyl ketone (MEK). It is adhesion to the silane, i.e., γ-cyclopropoxypropyltrimethoxysilane (which is sold in the trade name Silquest A-187) TM (USA, New York, Waterford, Momentive Performance Materials) Sales) and 醌 (in KEYPLAST TM BLUE A (USA, South Carolina, Spartan, Morinken) is sold in MEK and cyclohexanone.

[0131] Table 5. Other 1K adhesive formula

[0132]

[0133] The bind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com