Integrated steam aerated concrete production equipment and aerated concrete manufacturing process

A kind of technology of air-entrained concrete and production equipment, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc. It can solve the problems of not having integrated production conditions, unfavorable long-term sustainable development, and great demand for manpower and material resources, etc. problems, to achieve the effect of reasonable facility layout, saving manpower and material resources, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

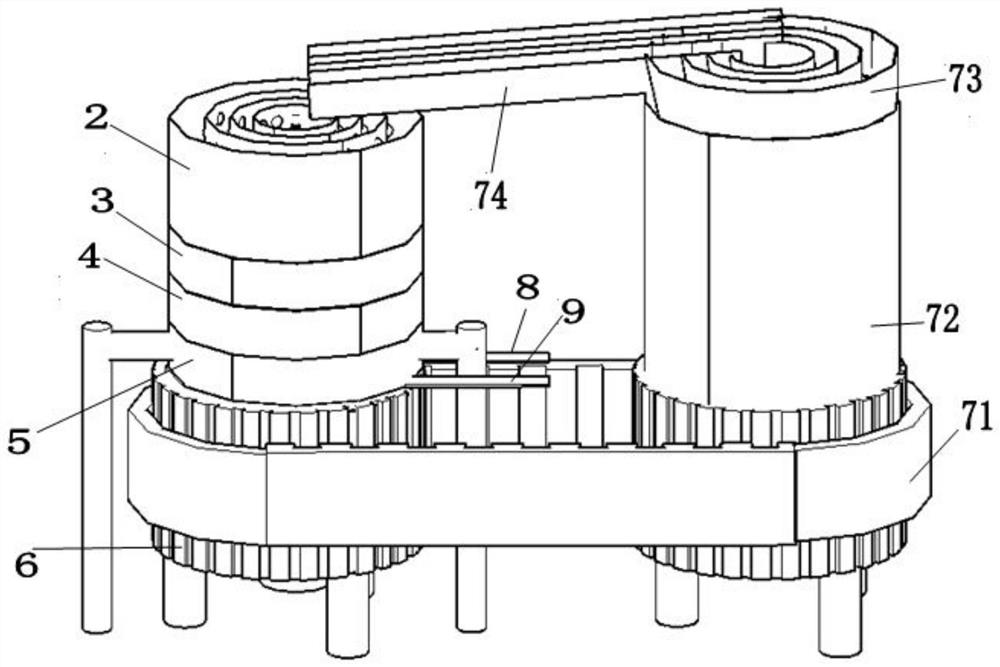

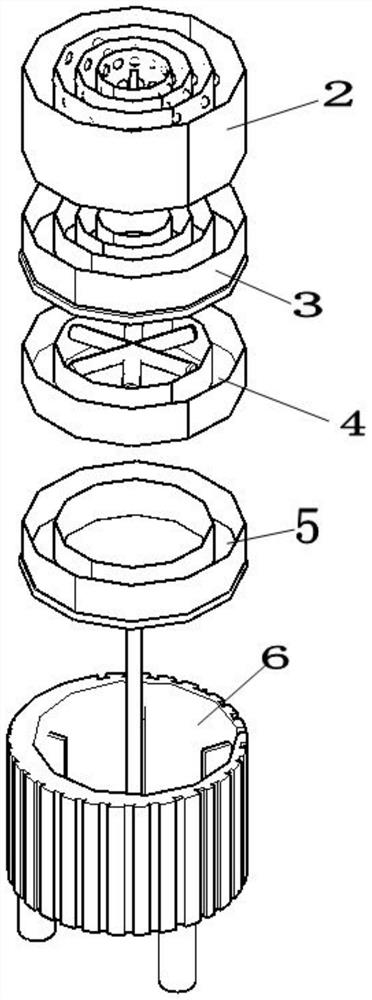

[0032] Such as Figure 1-7 As shown, an integrated steam aerated concrete production equipment includes a grinding area 2, a material preparation area 3, a mixing area 4, a storage area 5, a mixing area 6, and a belt 71 and a mixing area that are stacked sequentially from top to bottom. 6 connected to the feeding area 7; it also includes a drive mechanism 1 fixedly installed at the bottom of the mixing area 6, which drives the equipment to work by driving the rotating shaft 11 running through the mixing area 6.

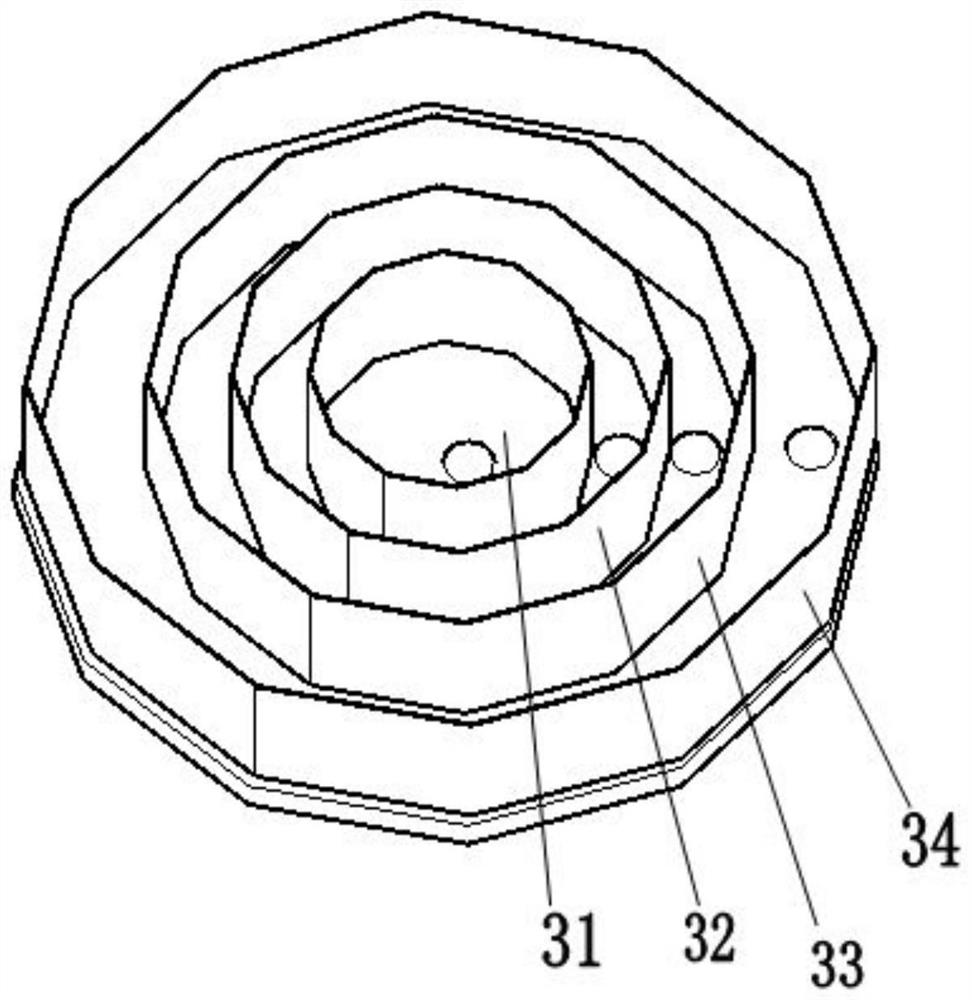

[0033] The feeding area 7 is the initial feeding mechanism, relying on the belt 71 to link with the mixing area 6. The discharging area 7 is composed of the discharging bin 72 and the track 74. The outer part of the discharging bin 72 is cylindrical, and the lower end is equipped with tooth marks and is driven by the belt 71. Driven to rotate, its interior has the same structure as that of the grinding area 2, and four bins are arranged sequentially from the inside to...

Embodiment 2

[0040]As a further improvement to Example 1, such as Figure 8 As shown, in each warehouse of the grinding area 2, a counter plate fixed on the grinding disc 26 is set, and the first storehouse 21, the second storehouse 22, the third storehouse 23 and the lime storehouse 24 are provided with a counter plate one 211 and a counter plate respectively. The second 221, the third 231 of the bottom plate, and the fourth 241 of the bottom plate can push the material to rub against the grinding column 25 when the equipment is started, so that the material can be fully polished in the grinding area 2, which is beneficial to the subsequent stirring of the material.

Embodiment 3

[0042] As a further improvement to the above-mentioned technical scheme, a stirring structure is provided inside the slurry bin 51 of the storage area 5, and the stirring structure can adopt the stirring rod 43 used in the stirring area 4, or a conventional stirring tool can be used to connect with the rotating shaft 11 , carry out secondary stirring on the material, fully mix, and improve the quality of the slurry.

[0043] A process for producing aerated concrete using the above-mentioned integrated steam aerated concrete production equipment, the steps are as follows:

[0044] Step 1: Put the required materials into the discharge bin 72 for storage;

[0045] Step 2: start the driving mechanism 1, the rotation of the belt 71 causes the discharge bin 72 to rotate to generate centrifugal force, and the material is brought into the shovel 73 by the centrifugal force, and enters the grinding area 2 through the track 74;

[0046] Step 3: The material is ground into the lower pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com