Spinnable polyamide as well as preparation method and product thereof

A technology of polyamide and aliphatic polyamide, which is applied in the field of spinnable polyamide and its preparation, can solve the problems of low melt thermal stability, low production rate, poor spinnability, etc., and can reduce the evenness rate , The effect of reducing the preparation cost and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

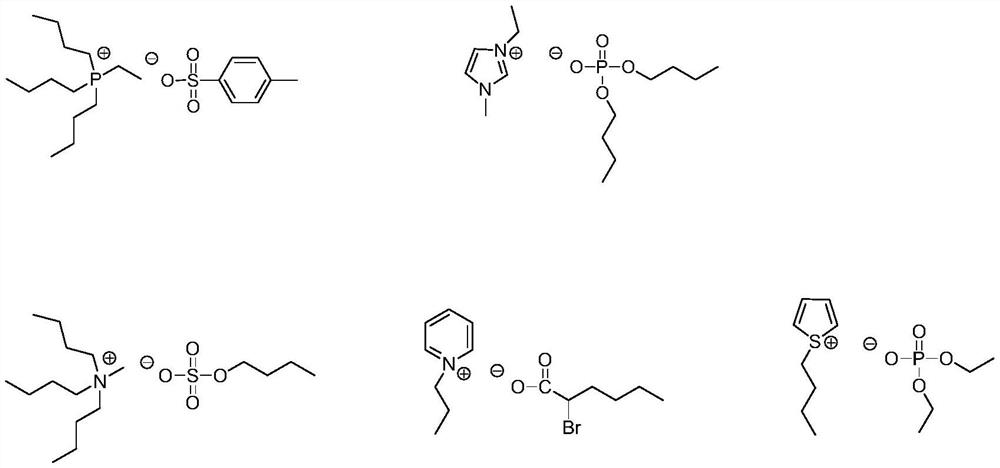

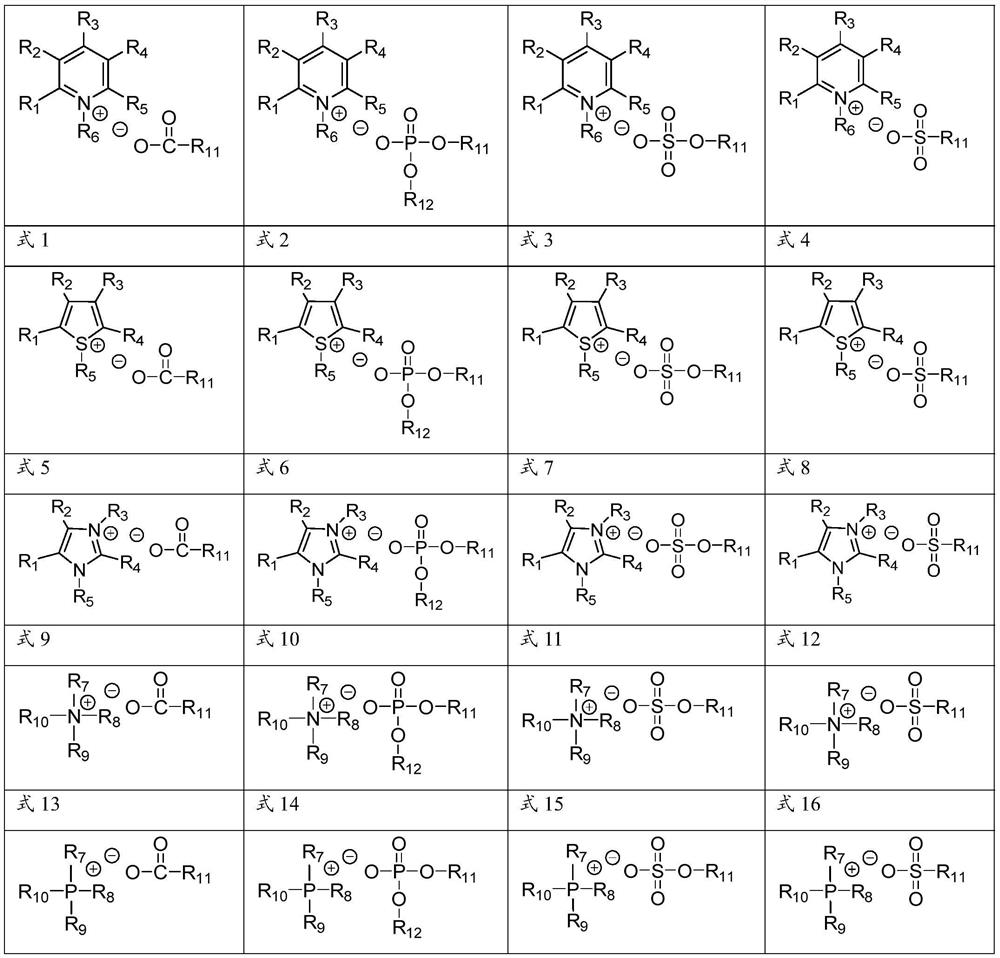

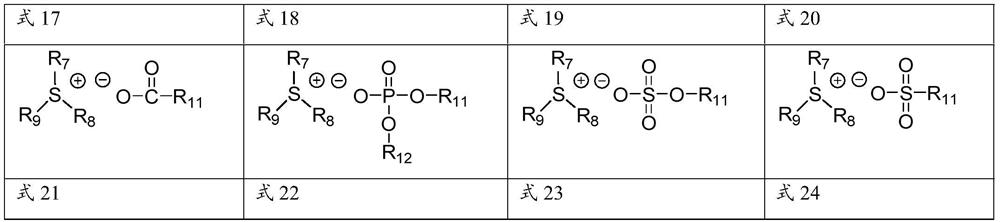

[0045] The preparation method of an exemplary embodiment of the present disclosure includes: using a spinnable polyamide monomer as a reaction base material, and preparing a spinnable polyamide by polymerization; wherein, before the end of the polymerization reaction, at least mixing the reaction base material with at least one A mixture of ionic compounds.

[0046] The inventors found that by adding the ionic compound of the present disclosure during the preparation of the aliphatic polyamide, the ionic compound can be fully and uniformly mixed with the molecular chains of the aliphatic polyamide without agglomeration. The uniformly dispersed ionic compound can enhance the aliphatic polyamide and enhance the spinnability of the dimonomer aliphatic polyamide, and reduce the number of yarn breakages of the dimonomer aliphatic polyamide during spinning. However, when the spinnable polyamide comprising dimonomer aliphatic polyamide is directly blended with the disclosed ionic com...

Embodiment 1

[0086] A kind of spinnable polyamide, its preparation method comprises:

[0087] S1. Salt forming section: Replace the air in the 20-liter polymerization kettle by vacuuming and filling nitrogen three times, and protect it with nitrogen, add 6kg of pure water, then add 2.66kg of hexamethylenediamine, start stirring, and add 3.34kg Adipic acid was used to prepare nylon salt solution, and the pH value of the nylon salt solution was adjusted to 10% concentration with a small amount of hexamethylenediamine or adipic acid. When the pH value was 7.85, 30 g of ionic compound 1 and 30 g of ionic compound 4 were added.

[0088] S2. Pre-polymerization section: Gradually raise the temperature of the 20-liter oil bath of the polymerization tank to 290°C, wait for the pressure inside the tank to rise to 1.8Mpa, start exhausting, and continue to heat up. When the temperature of the system reaches 242°C, it is gradually reduced to normal pressure. The process control is completed within 3 h...

Embodiment 2

[0092] A kind of spinnable polyamide, its preparation method comprises:

[0093] S1. Salt forming section: replace the air in the 20-liter polymerization kettle by vacuuming and filling nitrogen three times, and protect it with nitrogen, add 2.57kg of pure water, then add 2.66kg of hexamethylenediamine, start stirring, add 3.34 kg adipic acid to prepare the nylon salt solution, adjust the pH value of the nylon salt solution to 10% concentration with a small amount of hexamethylenediamine or adipic acid, and then add 1.2 g of sodium hypophosphite.

[0094] S2. Pre-polymerization section: gradually raise the temperature of the 20-liter oil bath of the polymerization tank to 300°C, wait until the pressure in the tank rises to 2.5Mpa, then add 6g of ionic compound 2, start to exhaust, and continue to heat up. When the temperature of the system reaches 245°C, it is gradually reduced to normal pressure. The process control is completed within 6 hours.

[0095] S3. Final polymeriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com