High-bonding-strength PVDF (polyvinylidene fluoride) coated diaphragm and preparation method thereof

A coating and diaphragm technology, applied in the direction of separator/film/diaphragm/spacer components, electrical components, circuits, etc., can solve the problem of large density difference between PMMA powder and PVDF powder, high equipment requirements, affecting volume and weight, etc. problem, to achieve the effect of simple and fast batching process, improved cycle performance and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

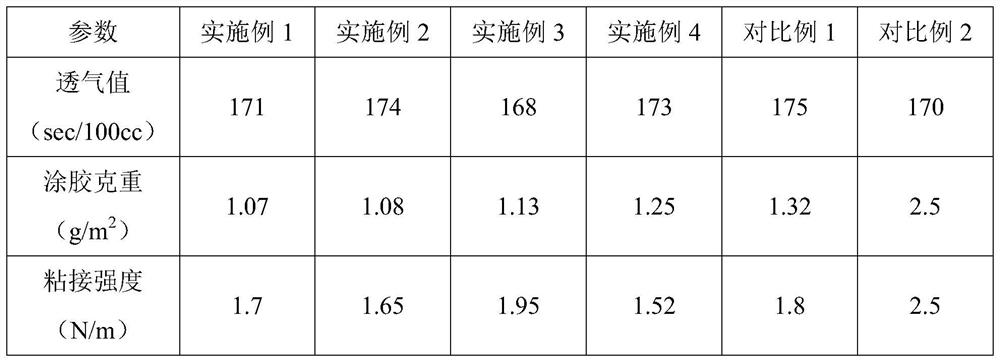

Examples

Embodiment 1

[0028] Example 1 Preparation of high adhesive strength coated diaphragm with PVDF / PMMA mixing ratio of 2:8

[0029] Add PVDF (manufacturer: CERTIFICATE OF ANALYSIS, model: LBG) into the PMMA emulsion (manufacturer: High Chemical (Shanghai) International Trade Co., Ltd., model: CL-3610), stir evenly, and add additives, which include additives. Thickening agent, wetting agent and binder; the order of adding additives is to add thickening agent first, knead for 100 min, after reaching the kneading state, add pure water to disperse for 30 min, then add wetting agent and binder and stir for 20 min; coating material;

[0030] The coating material is coated on the smooth side of the base diaphragm to prepare the high adhesive strength coated diaphragm.

[0031] The basic diaphragm in this embodiment is a polyethylene diaphragm.

[0032] The thickness of the basic diaphragm in this embodiment is 7 μm, the porosity is 30-40%, and the air permeability value is 100-200.

[0033] The t...

Embodiment 2

[0038] Example 2 Preparation of high bonding strength coated diaphragm with PVDF / PMMA mixing ratio of 4:6

[0039] Other operations are the same as in Example 1, except that the dosage of coating raw materials is replaced by: 40 parts of PVDF, 60 parts of PMMA emulsion, 0.6 parts of thickener, 6.9 parts of wetting agent, and 2.8 parts of binder.

Embodiment 3

[0040] Example 3 Preparation of high bonding strength coated diaphragm with PVDF / PMMA mixing ratio of 6:4

[0041] Other operations are the same as in Example 1, except that the dosage of coating raw materials is replaced by: 60 parts of PVDF, 40 parts of PMMA emulsion, 0.9 parts of thickener, 9.75 parts of wetting agent, and 4.2 parts of binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com