Motor and vehicle

A conductive bearing and conductive connection technology, applied in the field of motors and vehicles, can solve the problems of shaft current breakdown of bearing oil film, damage to bearing structure, arc scars of components, etc., to avoid unstable connection, reduce external force, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

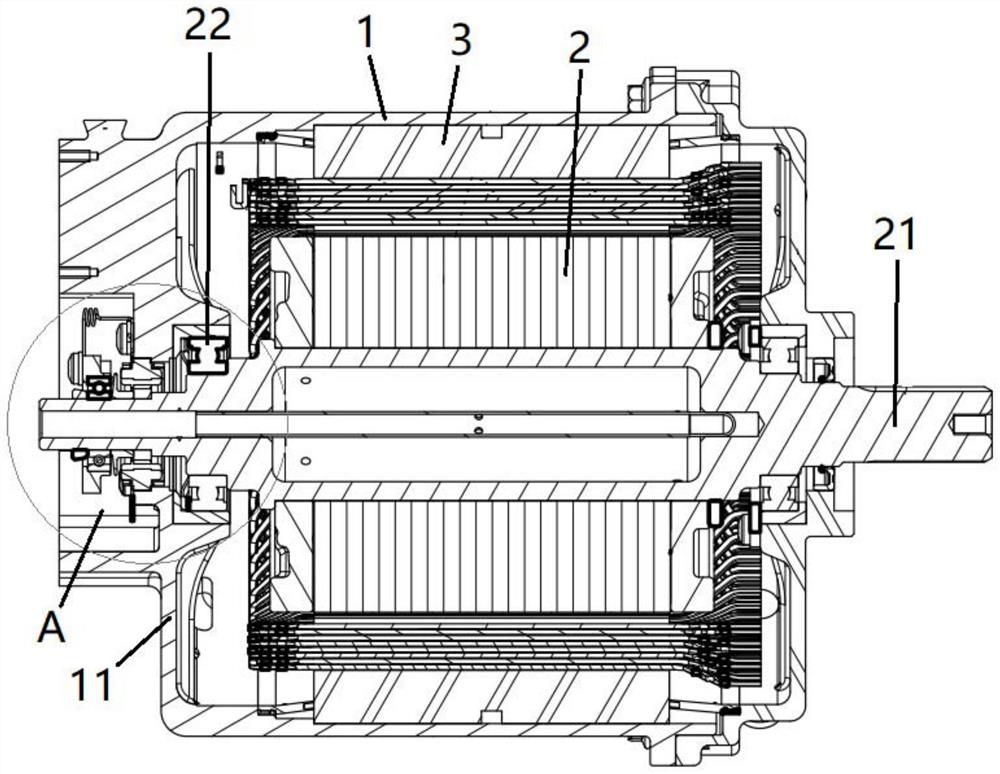

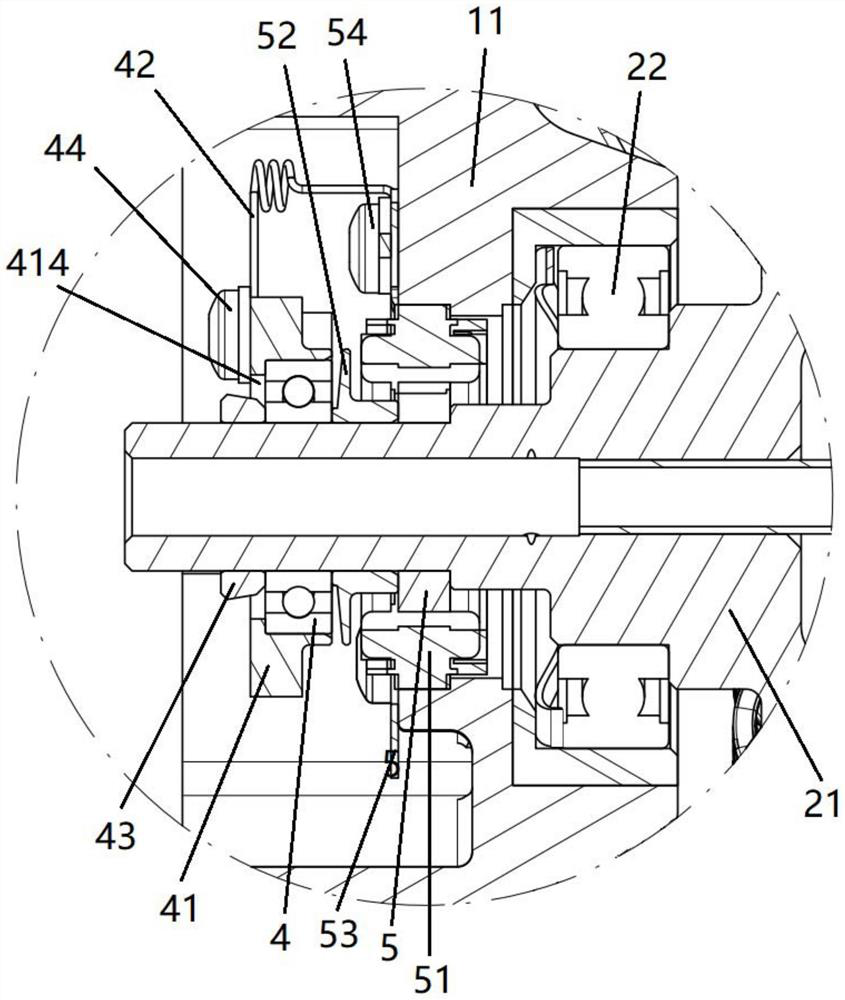

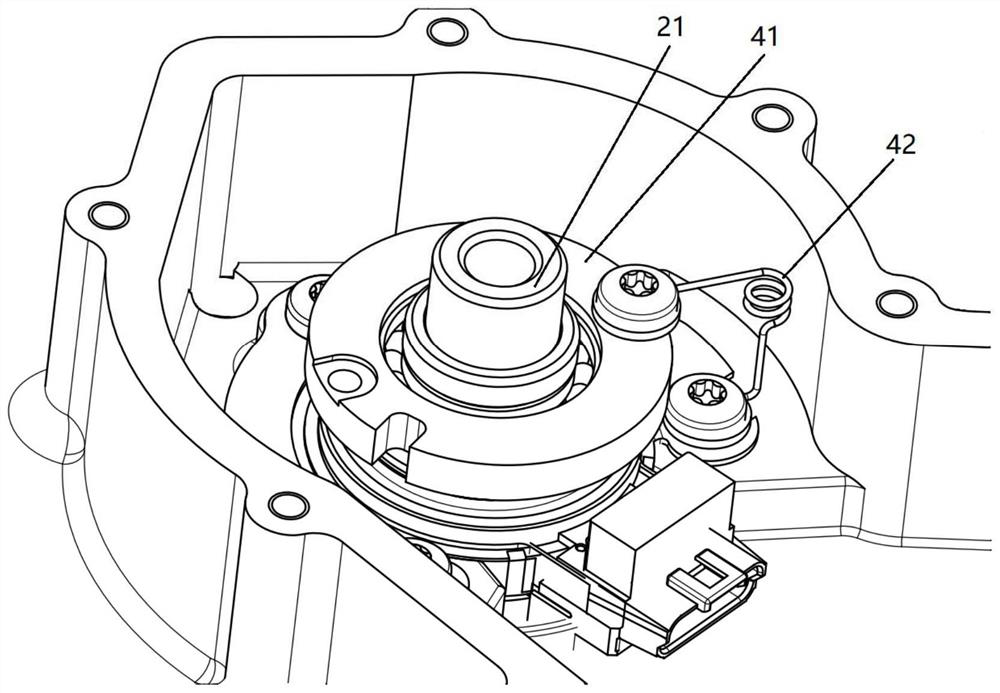

[0037] The invention provides a motor, such as figure 1 As shown in -8, the motor includes a housing 1, a stator assembly 3 and a rotor assembly 2.

[0038] The stator assembly 3 is fixed on the housing 1 . The stator assembly 3 includes stator windings, through which a rotating magnetic field is generated.

[0039] The rotor assembly 2 includes a rotating shaft 21 , and the rotating shaft 21 includes an end portion of the rotating shaft. The rotating shaft 21 is rotatably mounted on the housing 1 through a main bearing 22 .

[0040] Optionally, the rotor assembly 2 also includes rotor windings. When the motor is running, the rotor assembly 2 is located in the magnetic field generated by the stator windings. The assembly 3 generates torque, thereby causing the rotating shaft 21 to rotate around its axis and output driving torque; or, the rotor assembly 2 also includes an iron core and magnetic steel. When the motor is running, three-phase current is passed into the stator wi...

Embodiment 2

[0071] The present invention also provides a vehicle, which includes the motor described in the above technical solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com