Surface modification method of high-nickel positive electrode material and modified high-nickel positive electrode material

A technology of surface modification and positive electrode materials, applied in chemical instruments and methods, nickel compounds, battery electrodes, etc., can solve the problems of increased specific surface area, blockage of lithium ion transmission path, high residual alkali of ternary materials, etc., to achieve stable growth performance, capacity enhancement and cycle stability, and capacity and cycle stability performance reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] It should be added that the preparation method of the nickel-cobalt-manganese ternary positive electrode material can refer to the prior art, which is not limited here. In some embodiments, the preparation process of the nickel-cobalt-manganese ternary positive electrode material includes: uniformly mixing the precursor, the lithium source and the dopant for sintering, and the dopant is selected from Zr, Sr, Y, Mo and Mg At least one; the precursor can be Ni 0.92 co 0.04 mn 0.04 (OH) 2 , The sintering temperature is 700-750°C, and the holding time is 10-15h.

[0038] S2, coating

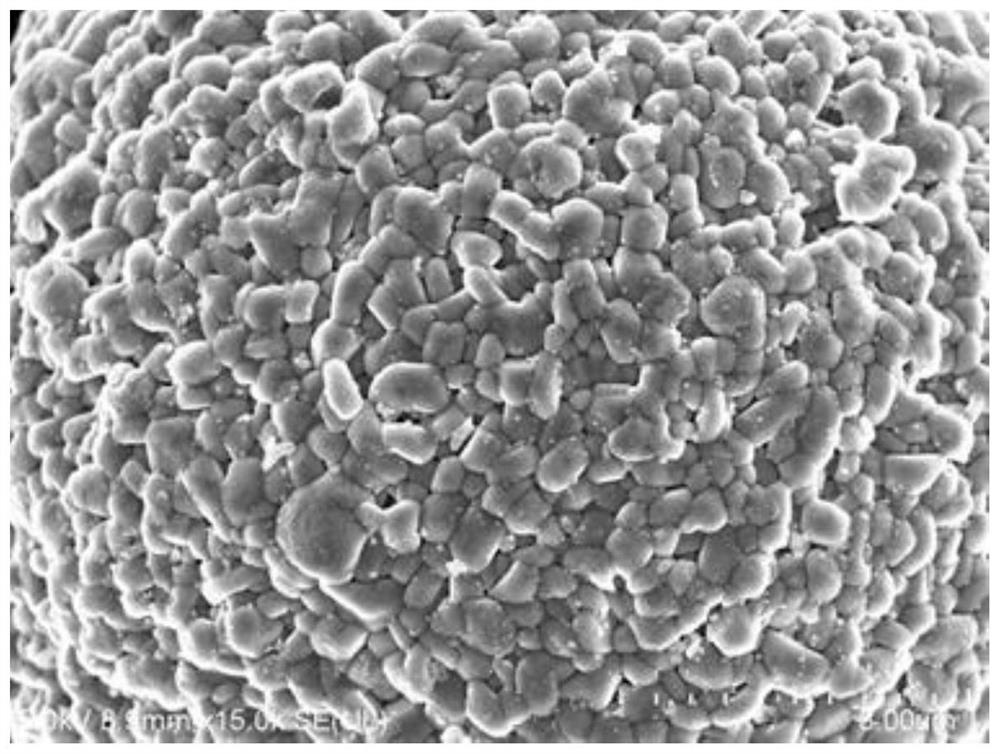

[0039] The material after pickling is mixed and sintered with a covering agent; wherein, the covering agent contains elements W, Al and B. During the sintering process, W and B enter the grain boundary to fill the grain boundary to reduce the specific surface area of the material, and Al is used to increase the stability of the material interface. After sintering, the capacity and cycle...

Embodiment 1

[0049] This embodiment provides a method for surface modification of a high-nickel positive electrode material, including:

[0050] will Ni 0.92 co 0.04 mn 0.04 (OH) 2 Precursor 500g and monohydrate lithium hydroxide 239.3g, and dopant SrCO 3 2.11g, Y 2 o 3 0.64g, MgO 0.37g, MoO 3 0.90g, after mixing evenly, raise the temperature to 730°C at a heating rate of 3°C / min and keep it for 12h. After one firing, the high-nickel material LiNi is obtained 0.92 co 0.04 mn 0.04 o 2 , cross a 400-mesh sieve for subsequent use.

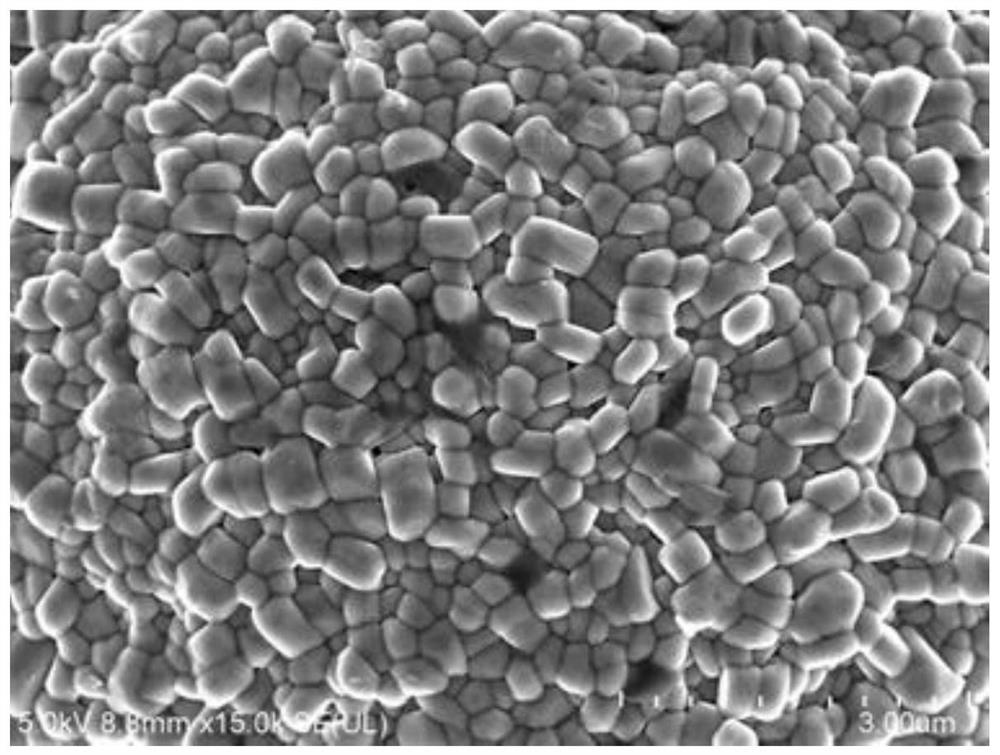

[0051] Take 500g of one-fired high-nickel material LiNi 0.92 co 0.04 mn 0.04 o 2 , the material is immersed in an oxalic acid solution with a mass fraction of 2% and a volume of 500ml. The immersion time is 3 minutes. After suction filtration, it is dried until the material moisture is less than 0.1%. At this time, the specific surface area of the material is detected (specific surface area 1.12m 2 / g).

[0052] Weigh the washed material 300g, ...

Embodiment 2

[0058] This embodiment provides a method for surface modification of a high-nickel positive electrode material, including:

[0059] will Ni 0.92 co 0.04 mn 0.04 (OH) 2 Precursor 500g and lithium hydroxide monohydrate 239.3g, and dopant ZrO 2 2.03g, Y 2 o 3 0.64g, MgO 0.37g, after mixing evenly, raise the temperature to 730°C at a heating rate of 3°C / min and keep it for 12h. After one firing, the high-nickel material LiNi is obtained. 0.92 co 0.04 mn 0.04 o 2 , cross a 400-mesh sieve for subsequent use.

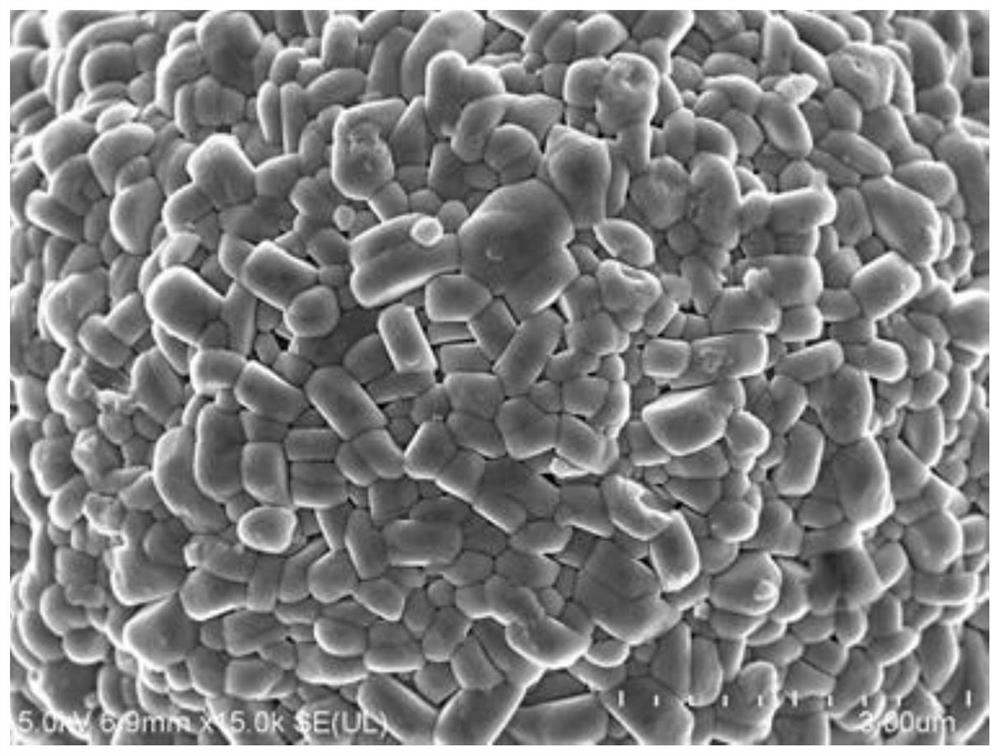

[0060] Take 500g of one-fired high-nickel material LiNi 0.92 co 0.04 mn 0.04 o 2 , the material is immersed in an oxalic acid solution with a mass fraction of 2% and a volume of 500ml. The immersion time is 3 minutes. After suction filtration, it is dried until the material moisture is less than 0.1%. At this time, the specific surface area of the material is detected (specific surface area 1.08m 2 / g).

[0061] Weigh the washed material 300g, and coating age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com