A modified high-nickel ternary positive electrode material and its preparation method and application

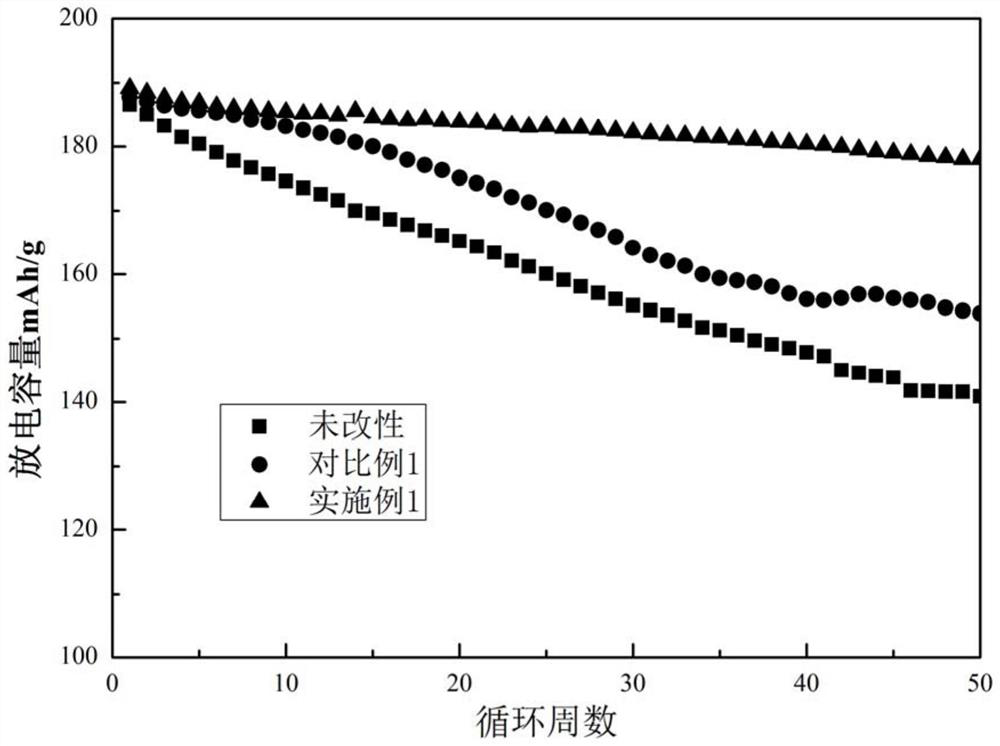

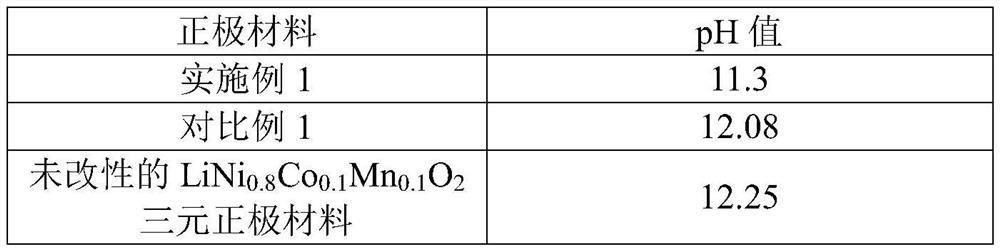

A cathode material, high-nickel technology, applied in the field of electrochemistry, can solve problems such as loss, and achieve the effects of low cost, excellent cycle stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This implementation provides a modified LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of ternary cathode material, it comprises the following steps:

[0039] Step 1, dissolve 10.7121g lithium acetate in 100ml deionized water to prepare 1mol / L lithium acetate solution, respectively dissolve 19.9072g nickel acetate, 2.4509g manganese acetate, and 2.4908g cobalt acetate in deionized water to prepare 1mol / L Solution, slowly add the two solutions into the beaker using a constant flow pump, adjust the pH between 7-8 with ammonia water during the reaction, and stir magnetically for 60 minutes after the reaction is completed;

[0040] Step 2: Weigh 1.5803g of potassium permanganate solid, dissolve it in deionized water and make up to 100ml, and prepare a 0.1mol / L potassium permanganate solution; stir at 25°C for 1 hour to form a uniform and stable potassium permanganate solution;

[0041] Step 3: Add 20ml of 0.1mol / L potassium permanganate solution to the mixed reactio...

Embodiment 2

[0054] This embodiment provides a modified LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of ternary cathode material comprises the following steps:

[0055] Step 1, dissolve 10.7121g lithium acetate in 100ml deionized water to prepare 1mol / L lithium acetate solution, respectively dissolve 19.9072g nickel acetate, 2.4509g manganese acetate, and 2.4908g cobalt acetate in deionized water to prepare 1mol / L Solution, slowly add the two solutions into the beaker using a constant flow pump, adjust the pH between 7-8 with ammonia water during the reaction, and stir magnetically for 60 minutes after the reaction is completed;

[0056] Step 2: Weigh 3.1606g of potassium permanganate solid, dissolve it in deionized water to 100ml, and prepare a 0.2mol / L potassium permanganate solution; stir at 25°C for 1 hour to form a uniform and stable potassium permanganate solution;

[0057] Step 3: Add 20ml of 0.2mol / L potassium permanganate solution to the mixed reaction solution in step 1...

Embodiment 3

[0059] This embodiment provides a modified LiNi 0.8 co 0.1 Al 0.1 o 2 The preparation method of ternary cathode material comprises the following steps:

[0060] Step 1, dissolve 7.2397g lithium nitrate in 100ml deionized water and prepare 1mol / L lithium acetate solution, respectively dissolve 23.2648g nickel nitrate, 3.7531g aluminum nitrate, and 2.9105g cobalt nitrate in deionized water to prepare 1mol / L Solution, slowly add the two solutions into the beaker using a constant flow pump, adjust the pH between 7-8 with ammonia water during the reaction, and stir magnetically for 60 minutes after the reaction is completed;

[0061] Step 2: Weigh 3.1606g of potassium permanganate solid, dissolve it in deionized water to 100ml, and prepare a 0.2mol / L potassium permanganate solution; stir at 25°C for 1 hour to form a uniform and stable potassium permanganate solution;

[0062] Step 3: Add 20ml of 0.2mol / L potassium permanganate solution to the mixed reaction solution in step 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com