Ceramic glass, curved ceramic glass and preparation method thereof

A technology of ceramic glass and glass, applied in the preparation of curved ceramic glass, the field of curved ceramic glass, can solve the problems of devitrification, large size, reduced glass transmittance, etc., to reduce the softening temperature, increase the secondary crystallization temperature, The effect of not reducing the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

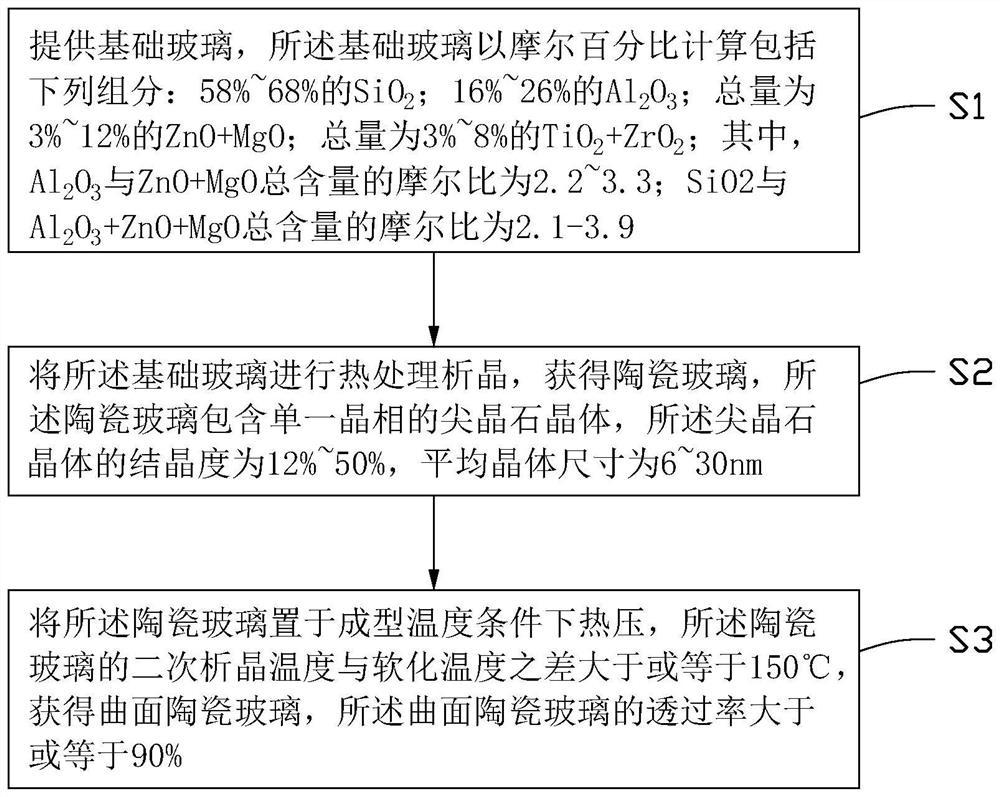

[0085] see figure 1 , the application also provides the preparation method of above-mentioned ceramic glass, and this preparation method comprises the following steps:

[0086] Step S1, providing a base glass, the base glass includes the following components calculated by mole percentage: 58%-68% SiO 2 ;16%~26% Al 2 o 3 ;The total amount is 3%~12% of ZnO+MgO; the total amount is 3%~8% of TiO 2 +ZrO 2 ; Among them, Al 2 o 3 The molar ratio to the total content of ZnO+MgO is 2.2 to 3.3; SiO 2 with Al 2 o 3 The molar ratio of the total content of +ZnO+MgO is 2.1-3.9.

[0087] Mix the above-mentioned components that make up the basic glass into a platinum crucible, melt it in a high-temperature lifting furnace at 1610°C to 1650°C, then shape the molten glass in a calender, and then put it into an annealing furnace for a long time at the annealing point. Gradient annealing to eliminate the internal stress of the glass. After the annealing is completed, the six sides of t...

Embodiment 2~4

[0115] Embodiment 2~4 and comparative example

[0116] The preparation method is the same as in Example 1, and the recipes and test parameters are shown in Table 1 and Table 2.

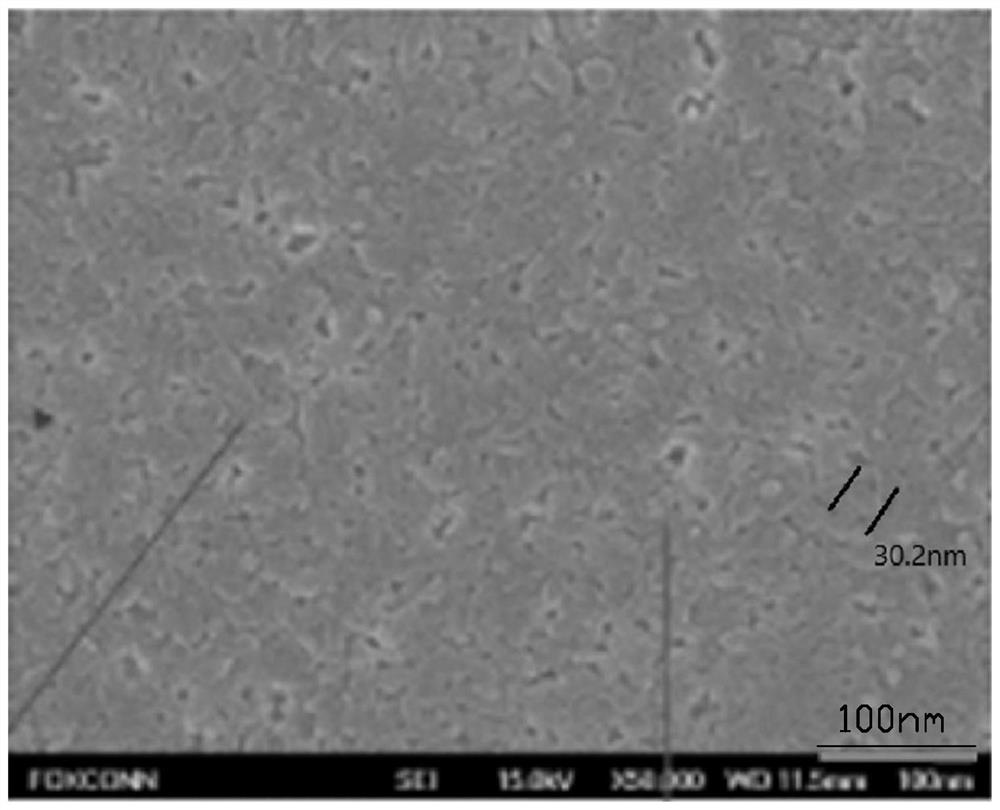

[0117] As can be seen from Table 2, the embodiment 1-4 of the present application controls the crystallinity and the average crystal size simultaneously through formula adjustment, so that the softening temperature of the ceramic glass of the embodiment 1-4 is compared with the comparative example 1, and the softening temperature is all reduced, while The secondary crystallization temperature all increased, and the difference between the softening temperature and the secondary crystallization temperature of the ceramic glasses in Examples 1-4 was greater than 150°C. In this way, the gap between the molding temperature range and the secondary crystallization temperature range of the ceramic glass during the hot-press molding process can be easily controlled to make the gap as large as possible, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap