Optical fiber reflection type hydrogen detector

A reflective and detector technology, which is applied in the field of optical fiber reflective hydrogen detectors, can solve the problems of high preparation difficulty, single mechanism, and low hydrogen detection sensitivity, and achieve high sensitivity and easy to change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

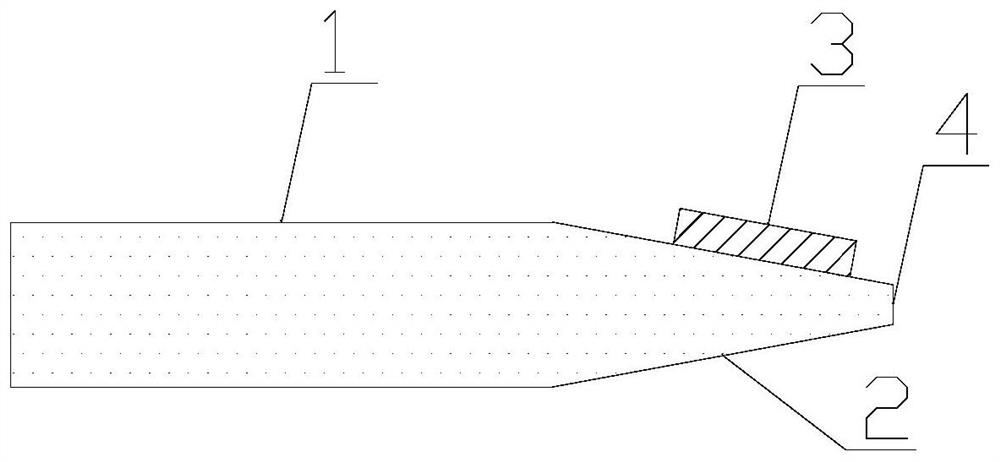

Embodiment 1

[0023] The invention provides an optical fiber reflective hydrogen detector, which includes a light source, an optical circulator, an optical detector, an optical fiber 1 and a palladium film 3 . Fiber 1 is a single-mode fiber. One end of the optical fiber 1 is connected to a light source and a photodetector through an optical circulator, and the other end of the optical fiber 1 is provided with a tapered region 2 . That is, in figure 1 In the figure, the left end of the optical fiber 1 is connected to an optical circulator, and the right end of the optical fiber 1 is provided with a tapered region 2 . exist figure 1 Among them, the left end of the tapered region 2 is connected to the optical fiber 1, and the right end of the tapered region 2, that is, the free end forms the end face 4 of the tapered region. In this embodiment, the single-mode fiber is selected because the core diameter of the single-mode fiber is small. When the tapered single-mode fiber is drawn, the tap...

Embodiment 2

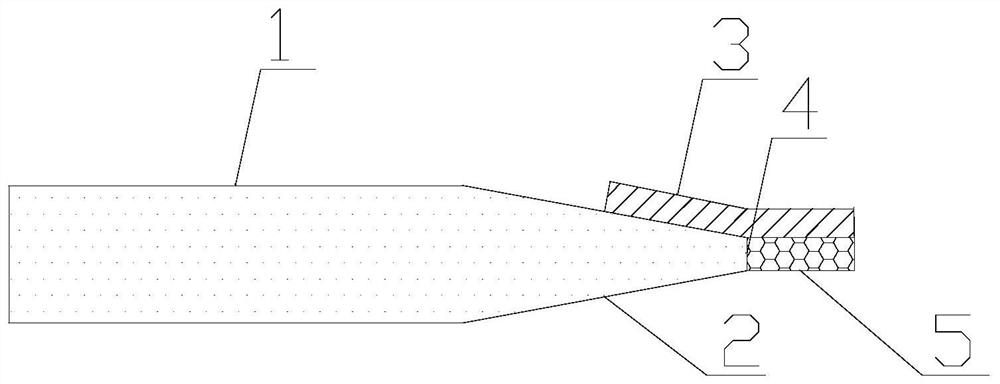

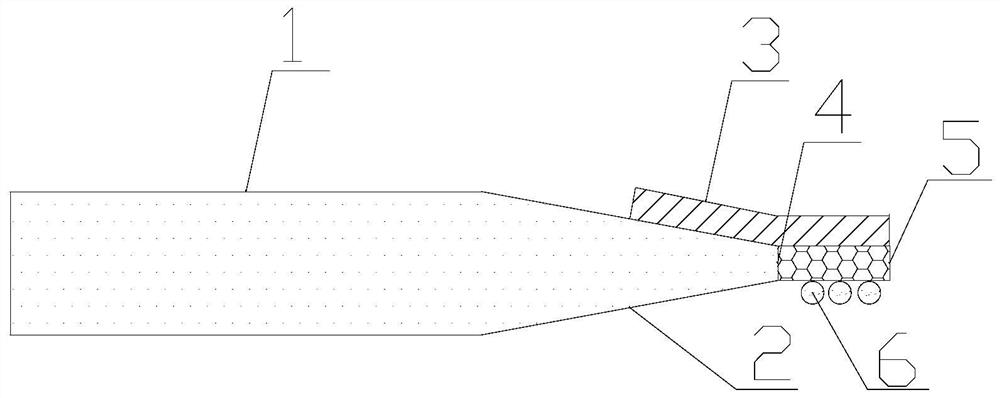

[0026] On the basis of Example 1, the palladium film 3 is arranged in a region close to the end face 4 of the tapered region. The diameter near the end face 4 of the tapered region is small, and when the palladium film 3 absorbs hydrogen and expands, it is more likely to cause the curved tapered region 2 to bend, thereby changing the light reflection characteristics of the tapered region 2 more, thereby realizing high-sensitivity hydrogen detection.

[0027] Furthermore, when the palladium film 3 is set near the end face 4 of the tapered area, the palladium film 3 partially covers the end face 4 of the tapered area, so that when the palladium film 3 absorbs hydrogen, the palladium film on the end face 4 of the tapered area The refractive index of 3 is also changed, thereby more changing the light reflection characteristics of the tapered region 2, so as to realize the detection of hydrogen with higher sensitivity.

Embodiment 3

[0029] On the basis of Example 2, such as figure 2 As shown, an elastic transparent part 5 is also included, and the elastic transparent part 5 is arranged on the end surface 4 of the tapered region, and the palladium film 3 extends to the elastic transparent part 5 . The end surface of the elastic transparent part 5 has the same shape as the end surface 4 of the tapered region, and the elastic transparent part 5 is fixed on the end surface 4 of the tapered region. The elastic transparent part 5 is made of PMMA. In this way, the light in the tapered region 2 can propagate into the elastic transparent part 5 . like figure 2 As shown, a part of the palladium film 3 covers the side of the tapered region 2 , and a part of the palladium film 3 covers the side of the elastic transparent part 5 . Because the elasticity of the elastic transparent part 5 is greater than the elasticity of the tapered region 2, when the palladium film 3 absorbs hydrogen and expands, the elastic tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com