Reflection electrode, preparation method thereof and LED chip

A technology of LED chips and reflective electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as poor adhesion between silver films and substrates, and achieve the effects of improving electrical properties, efficient bonding, and preventing reflectivity from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] Preferably, the method for preparing the reflective electrode further includes: vapor-depositing a metal protective layer on the metal covering layer.

[0097] More preferably, the evaporation rate of the metal protection layer is 1A / S˜4A / S, more preferably 1A / S˜3A / S.

[0098] In one embodiment, the evaporation rate of the metal protection layer is specifically 2A / S, 3A / S, 4A / S, etc., and other values within the above range can also be selected, which is not limited here.

[0099] According to another aspect of the present invention, the present invention also relates to an LED chip, comprising the above-mentioned reflective electrode.

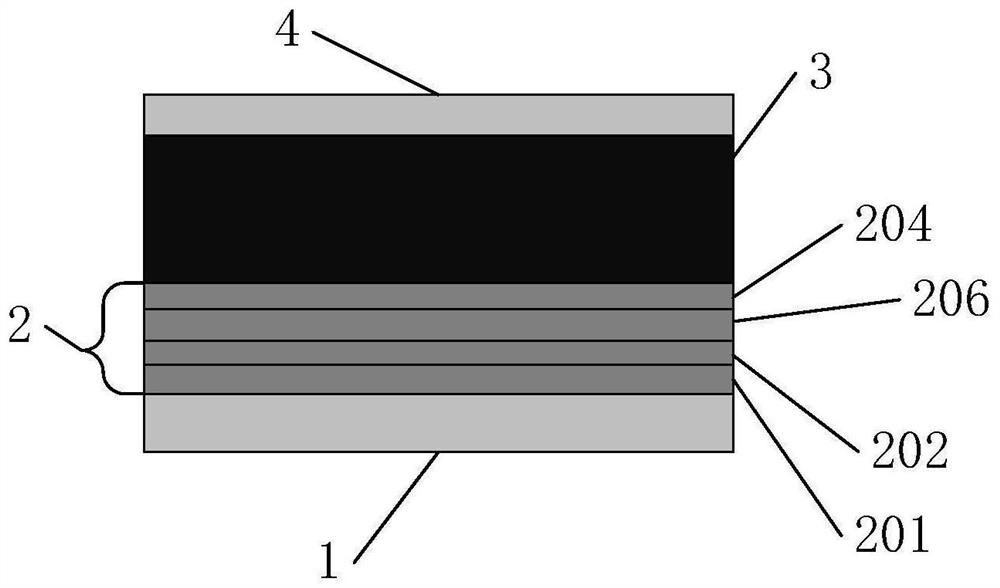

[0100] The reflective electrode of the present invention can be applied to LED chips, including front-mount, flip-chip or vertical structures. For example, you can attach Figure 6 The Ag mirror structure shown and the attached Figure 7 ODR structure shown.

[0101]Wherein, the Ag reflector structure includes: sapphire substrate,...

Embodiment 1

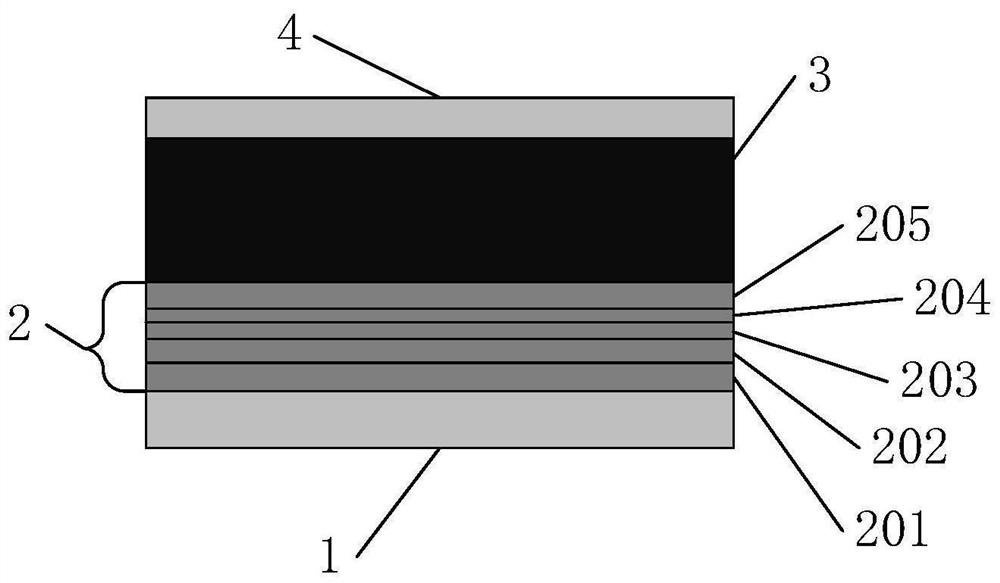

[0110] A reflective electrode, comprising a metal reflective layer 1, a stacked metal barrier layer 2, a metal covering layer 3 and a metal protective layer 4 arranged in sequence;

[0111] The metal reflective layer 1 is an Ag layer with a thickness of 1000A and a Mohs hardness of 2.5;

[0112] The stacked metal barrier layer 2 is a first Ti layer 201, a first Ni layer 202, a first Pt layer 203, a second Ni layer 204 and a second Pt layer 205 arranged in sequence, wherein the first Ti layer 201 Connected with the metal reflective layer 1, the first Ti layer 201 (Mohs hardness is 6), the first Ni layer 202 (Mohs hardness is 4), the first Pt layer 203 (Mohs hardness is 4.5), the second Ni layer The thicknesses of 204 (Mohs hardness is 4) and the second Pt layer 205 (Mohs hardness is 4.5) are 1000A, 600A, 600A, 600A, 600A;

[0113] The metal covering layer 3 is an Au layer with a thickness of 7000A and a Mohs hardness of 2.5;

[0114] The metal protective layer 4 is a Ti layer...

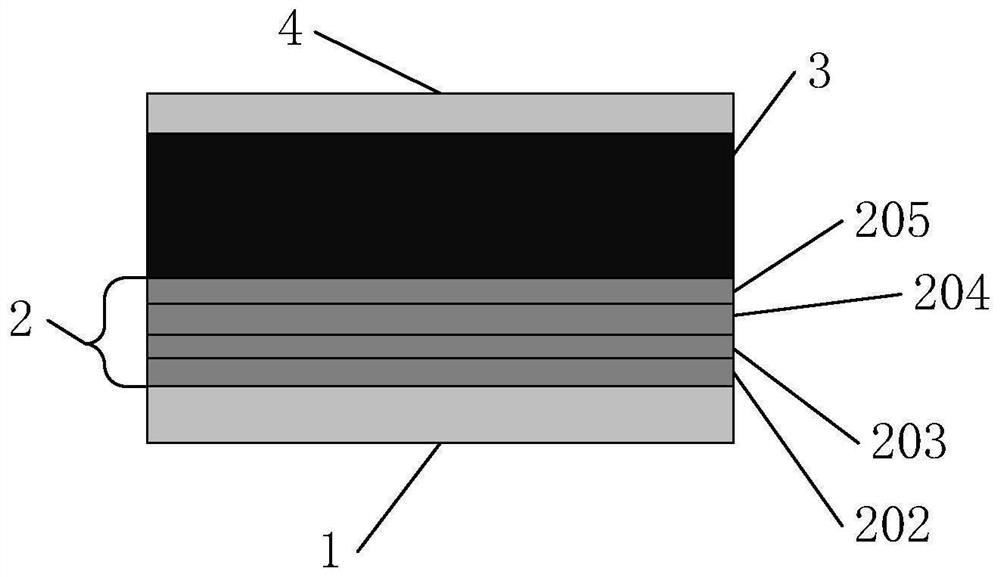

Embodiment 2

[0123] A reflective electrode, except that the laminated metal barrier layer 2 includes a first Ni layer 202, a first Pt layer 203, a second Ni layer 204, and a second Pt layer 205 that are sequentially connected, and the first Ni layer 202 is connected with the metal reflective electrode. The layers 1 are connected, the thicknesses of the first Ni layer 202 , the first Pt layer 203 , the second Ni layer 204 and the second Pt layer 205 are respectively 800 Å, and other conditions are the same as in the first embodiment.

[0124] The preparation method of the reflective electrode in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com