Liquid fermentation table vinegar and production method thereof

A production method and liquid fermentation technology are applied in the field of liquid fermented vinegar and its production, which can solve the problems of single flavor of liquid fermented vinegar and low conversion rate of alcohol to acetic acid, etc., and achieve the effects of improving single flavor, reducing dosage and shortening cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

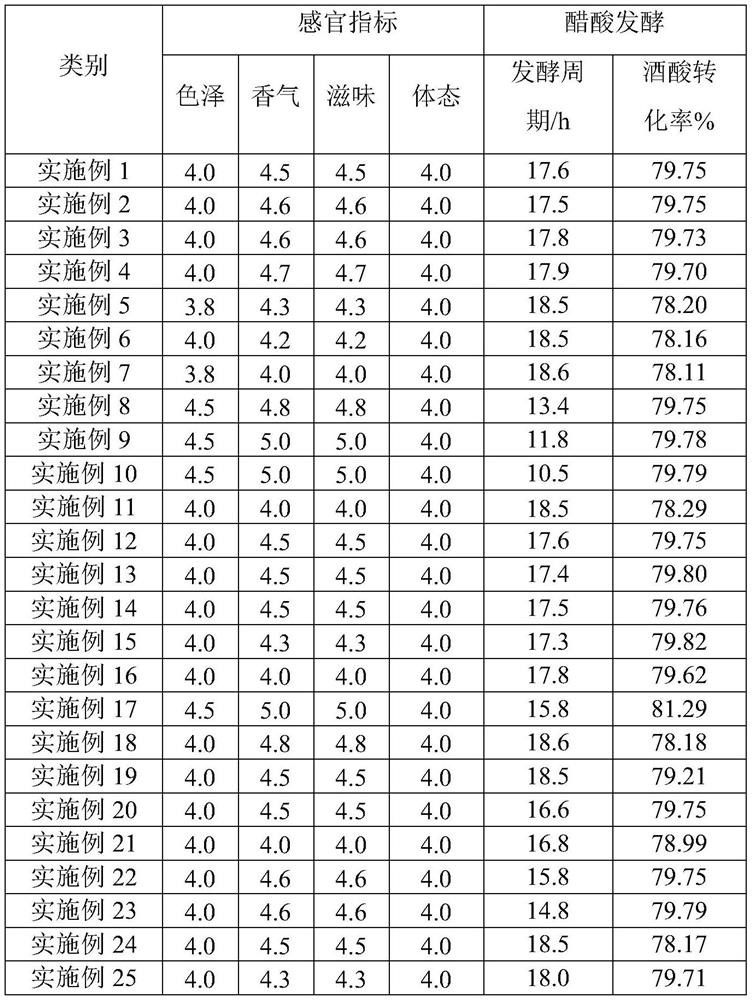

Embodiment 1

[0038] (1) Alcoholic fermentation: the grain (the mass ratio of glutinous rice and sorghum is 1:1) is crushed to obtain crushed material, and the mixed material is mixed according to the mass ratio of crushed material to water of 1:4, and then enzyme preparation is added for liquefaction, Saccharification treatment to obtain saccharified material; wherein the mass ratio of crushed material to enzyme preparation is 500:1.5, yeast is used to carry out alcoholic fermentation on saccharified material, the quality of yeast is 1% of the mass of saccharified material, and the temperature of alcoholic fermentation is 28~ 30°C, the time of alcoholic fermentation is 130h, and the wine mash is obtained.

[0039] (2) Acetic acid fermentation: the wine mash is transported to the full-automatic acetic acid fermentation tank and mixed with acetic bacteria (the quality of the acetic bacteria is 0.5% of the wine mash), apple juice (the apple juice is 0.5% of the total mass of the wine mash and ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that

[0045] The mass ratio of glutinous rice and sorghum is 3:2, and finally liquid fermented vinegar is obtained.

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 1 is that

[0048] The mass ratio of glutinous rice and sorghum is 7:3, and finally liquid fermented vinegar is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com