Beneficiation method for extracting high-purity silica powder from quartz tail mud

A mineral processing method and silicon micropowder technology, which is applied in the field of extracting high-purity silicon micropowder mineral processing, can solve the problems that valuable non-metallic minerals cannot be effectively recovered and utilized in time, impurities cannot be effectively removed, and the process is complicated, and the dehydration effect is obvious. , The effect of product purity improvement and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

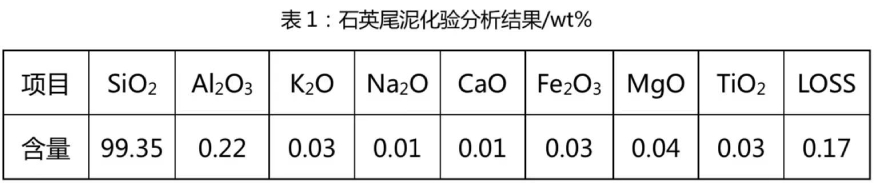

[0021] Taking the purified high-purity silicon powder of Qusi Tail mud for Yilong Mineral Company, Zhanjiang City, Guangdong Province, which is seen from the original mineral test results. figure 2 :

[0022] The sample mineral identification is as follows:

[0023] (1) The main component is SiO 2 , Main impurity elements are Al 2 O 3 K 2 O, NA 2 O, Cao, MGO, TIO 2 And Fe 2 O 3 Wait, the main impurity ingredient is mica, etc .;

[0024] (2) The product grain is fine: -0.12 ~ + 0.043mm accounted for 50% by weight, - 0.043 ~ + 0.020 mm accounted for 33 wt%, - 0.020mm accounted for 17% by weight.

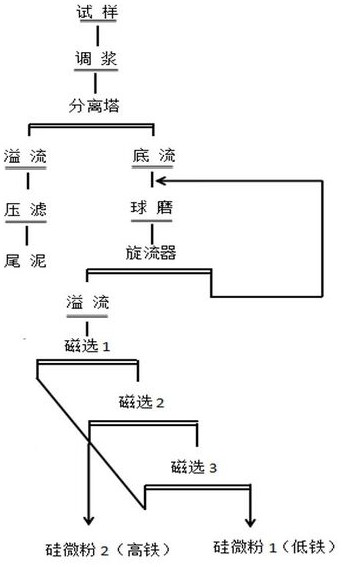

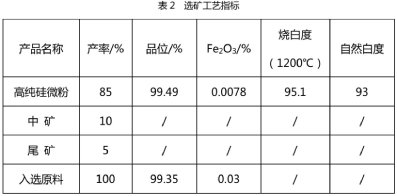

[0025] The quartz-British tubi sample uses the following process flow, the acquisition process indicator image 3 :

[0026] The process process is as follows:

[0027] 1. Feed: The raw material is given by a mixing barrel of a diameter of φ1 meter through the feeder, and the concentration is controlled at 25 to 30% by weight. The slurry is stirred from a stirred barrel pumped to another di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com