Preparation process of anti-interference soft magnetic ferrite core

A soft ferrite and preparation process technology, applied in inductor/transformer/magnet manufacturing, manufacturing tools, grinding workpiece supports, etc., can solve the problems of easy interference, difficult cleaning, and poor use of ferrite cores , to facilitate collection, enhance grinding effect, and enhance adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A preparation process for an anti-interference soft ferrite core, comprising the following steps:

[0043] S1. First, mix the soft ferrite core material, and spray and granulate the obtained mixture;

[0044] S2. Pressing and molding the product after spray granulation, and then placing it in a sintering furnace for sintering treatment to obtain a soft ferrite core blank;

[0045] S3. Grinding the edge of the soft ferrite core blank by a grinding device, and covering it with an anti-interference layer after grinding to obtain an anti-interference soft ferrite core product.

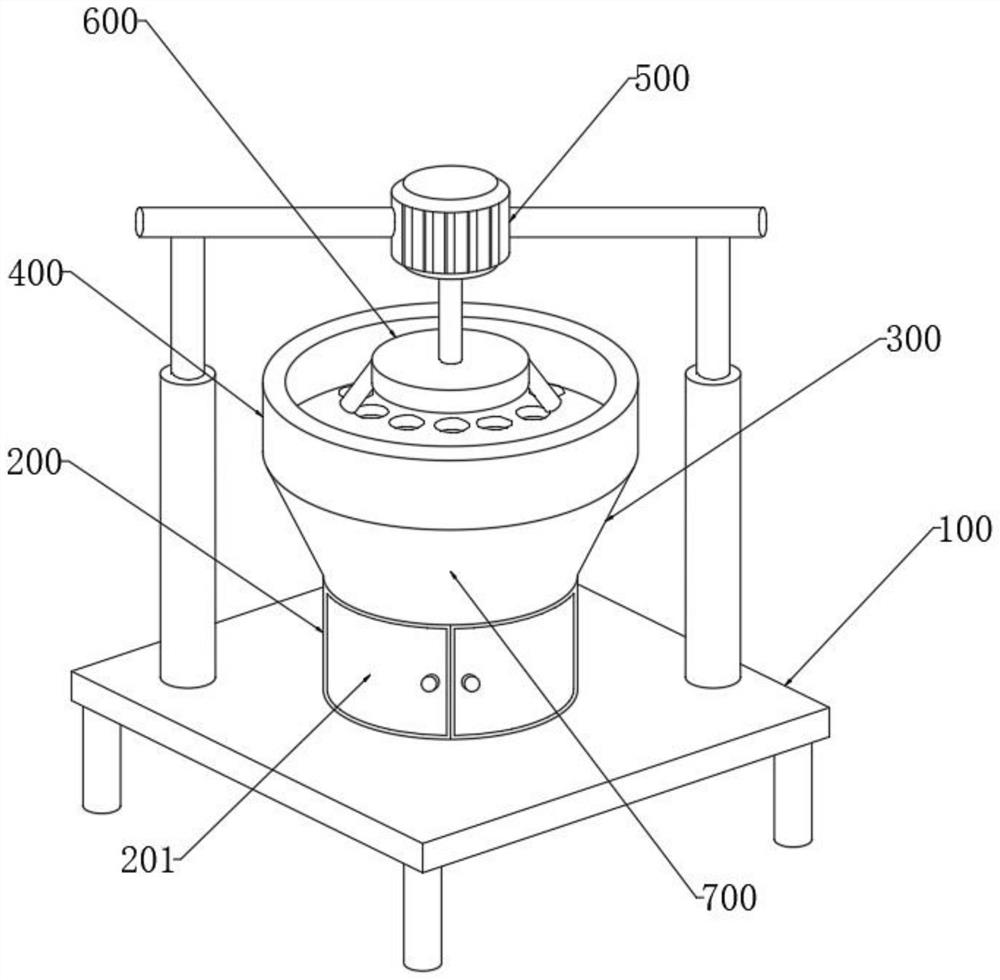

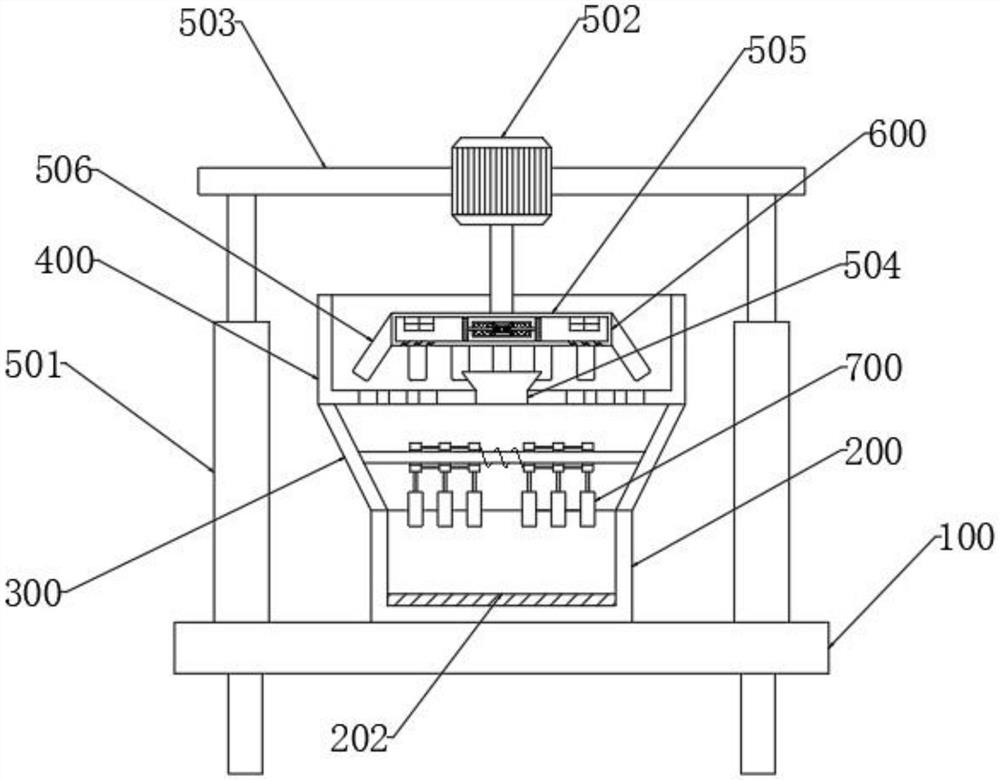

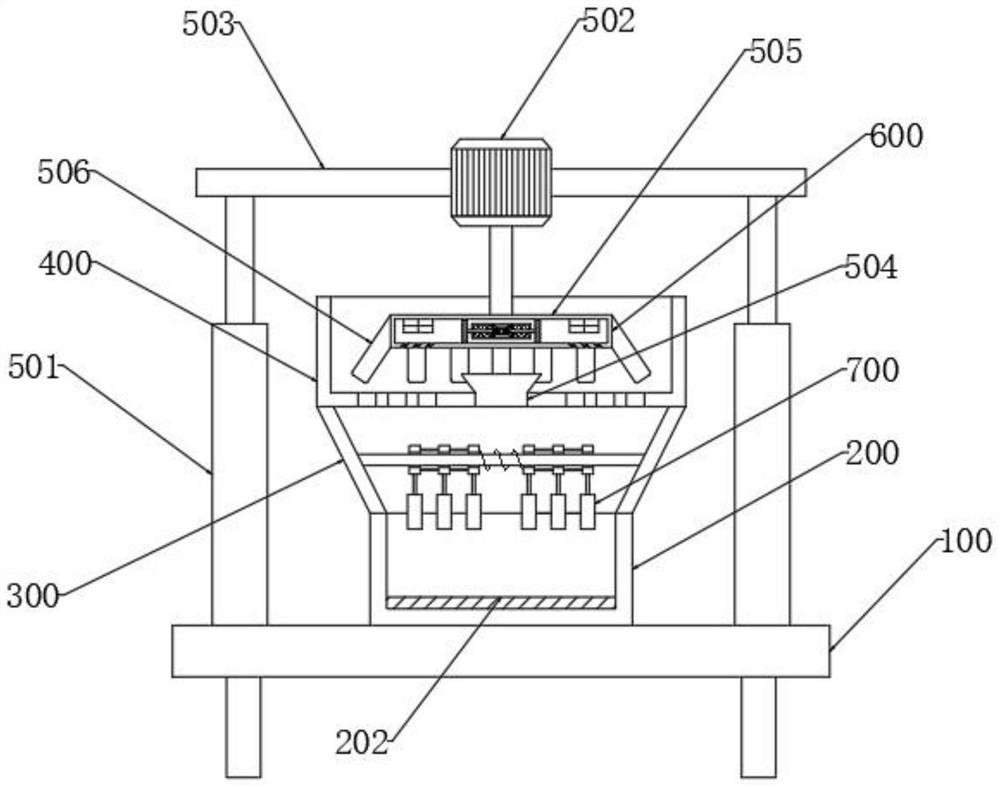

[0046] see Figure 1-6 , the grinding device in S3 comprises a workbench 100, the upper end of the workbench 100 is fixedly connected with a collection frame 200, the upper end of the collection frame 200 is fixedly connected with a guide hopper 300, and the guide hopper 300 communicates with the inside of the collection frame 200, the guide hopper The upper end of 300 is equipped with grinding ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com