Crushed stone seal layer maintenance material for mountain road and construction method of crushed stone seal layer maintenance material

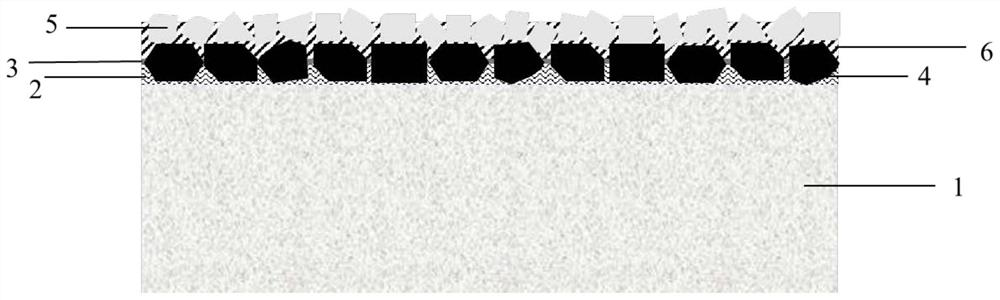

A kind of gravel sealing layer, highway technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve the problem of difficult to improve pavement performance and maintenance quality, pavement anti-skid coefficient and wear resistance attenuation, pavement structure and construction The method is not applicable, etc., to achieve high-value reuse, delay the reduction of wear coefficient and anti-skid performance, and improve the effects of insufficient lighting and poor sight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

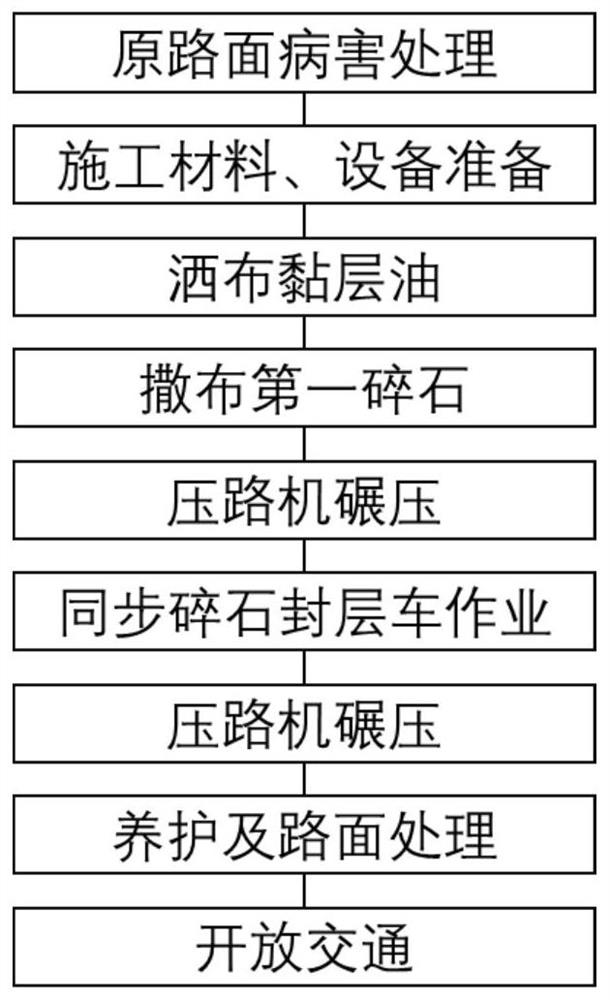

Method used

Image

Examples

Embodiment 1

[0086] The composition of the viscous oil used in this embodiment is:

[0087] 20% non-ionic water-based epoxy emulsion with emulsifier content 2.4kg

[0088] Cationic SBS modified emulsified asphalt 25.0kg

[0089] Polyamide 651 curing agent 0.8kg

[0090] Wherein, the preparation method of the nonionic water-based epoxy emulsion of 20% emulsifier dosage is as follows:

[0091] (1) Weigh 15.0kg of epoxy resin F51 and 120.0kg of polyethylene glycol PEG-4000 into the reaction kettle, set the temperature at 70°C, heat and stir until the polyethylene glycol PEG-4000 is completely dissolved, and keep the temperature constant After 2 hours of reaction, a mixture of epoxy resin F51 and PEG-4000 was obtained. Dissolve 0.5kg of potassium persulfate in 2.5kg of water to obtain an aqueous solution of potassium persulfate, slowly add the aqueous solution of potassium persulfate to the mixture of epoxy resin F51 and PEG-4000, and finish the dropwise addition within 0.5h, then evenly S...

Embodiment 2

[0104] The composition of the sticky layer oil used in this embodiment is:

[0105] 18% non-ionic water-based epoxy emulsion with emulsifier content 2.4kg

[0106] Cationic SBS modified emulsified asphalt 19.0kg

[0107] Diethylenetriamine curing agent 0.8kg

[0108] Wherein, the preparation method of the nonionic water-based epoxy emulsion of 18% emulsifier dosage is as follows:

[0109] The nonionic emulsifier was prepared according to the method in Example 1. Weigh 0.98kg of epoxy resin E51 and 0.22kg of non-ionic emulsifier into the reaction kettle, mix at 70°C for 30 minutes at high speed, then slowly add distilled water to the system until the viscosity of the system drops suddenly to form a stable water lotion. Continue to add water to dilute until the total amount of water added is 1.2kg to obtain a nonionic water-based epoxy emulsion with 18% emulsifier content, and its solid content is 50%.

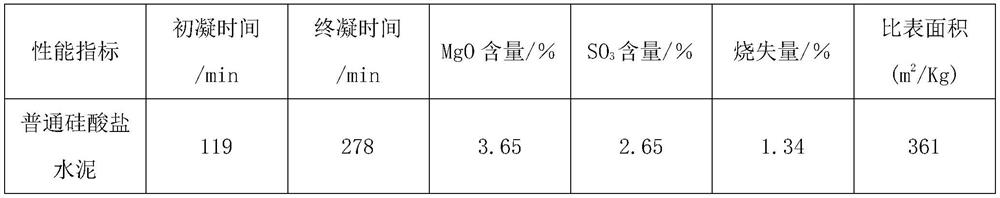

[0110] The composition of the cement used in this embodiment is:

[0...

Embodiment 3

[0118] The composition of the sticky layer oil used in this embodiment is:

[0119] 20% non-ionic water-based epoxy emulsion with emulsifier content 2.0kg

[0120] Cationic SBS modified emulsified asphalt 23kg

[0121] Diethylenetriamine curing agent 0.6kg

[0122] Wherein, the method for preparing the nonionic water-based epoxy emulsion of 20% emulsifier dosage is the same as that in Example 1.

[0123] The composition of the cement used in this example is:

[0124] Cationic water-based epoxy emulsion with 16% emulsifier content 14.0kg

[0125] Cationic SBS modified emulsified asphalt 95.0kg

[0126] Modified phenalkamine T30 curing agent 4.3kg

[0127] Wherein, the cationic water-based epoxy emulsion preparation method of 16% emulsifier dosage is as follows:

[0128] The cationic emulsifier was prepared according to the method in Example 1. 0.90 kg of cationic emulsifier and 0.22 kg of nonionic emulsifier were sheared at high speed for 15 minutes at room temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com