Carbon fiber modified polysilazane composite material for fire fighting helmet and preparation method thereof

A technology of polysilazane and composite materials, which is applied in the field of carbon fiber modified polysilazane composite materials and its preparation for fire helmets, achieving good application prospects, moderate penetration, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

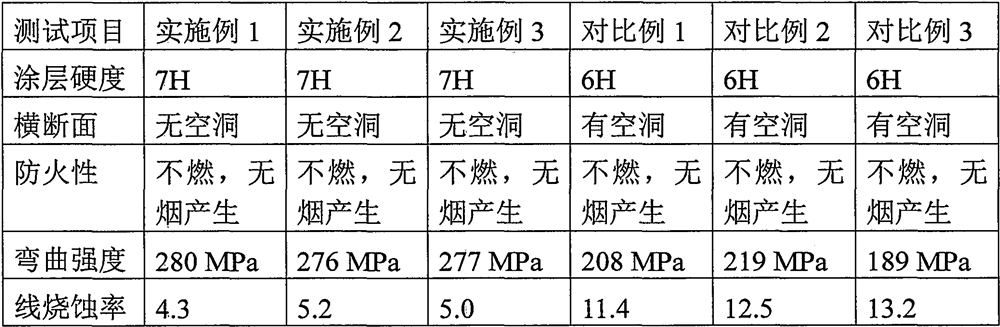

Examples

Embodiment 1

[0025] A carbon fiber modified polysilazane composite material, which includes a matrix and a reinforcement, the matrix is a mixture of silica airgel and polysilazane; the reinforcement is a copolymer of carbon fiber and styrene-vinyl fluoride mixture of things. The styrene-fluoroethylene copolymer is polystyrene-poly 2,3,4,5,6-pentafluorostyrene copolymer. Wherein, the mass ratio of the mixture of silica airgel and polysilazane as the matrix to the mixture of carbon fiber and styrene-fluoroethylene copolymer as the reinforcement is 100:100.

[0026] The mixture of silica airgel and polysilazane is prepared by the following method: adding the mixture of polysilazane, methyltriethoxysilane and ethyl orthosilicate to the ethanol solution, and adjusting the pH The value is 5, and supercritical carbon dioxide is introduced to react, and then supercritical drying is carried out to obtain the matrix.

[0027] The mixture of carbon fiber and styrene-fluoroethylene copolymer is pr...

Embodiment 2

[0030] A carbon fiber modified polysilazane composite material, which includes a matrix and a reinforcement, the matrix is a mixture of silica airgel and polysilazane; the reinforcement is a copolymer of carbon fiber and styrene-vinyl fluoride mixture of things. Styrene-fluoroethylene copolymer is polystyrene-poly-3-fluorostyrene copolymer. Wherein, the mass ratio of the mixture of silica airgel and polysilazane as the matrix to the mixture of carbon fiber and styrene-fluoroethylene copolymer as the reinforcement is 100:50.

[0031] The mixture of silica airgel and polysilazane is prepared by the following method: adding the mixture of polysilazane, methyltriethoxysilane and ethyl orthosilicate to the ethanol solution, and adjusting the pH The value is 4, and supercritical carbon dioxide is introduced to react, and then supercritical drying is carried out to obtain the matrix.

[0032] The mixture of carbon fiber and styrene-fluoroethylene copolymer is prepared by the foll...

Embodiment 3

[0035] A carbon fiber modified polysilazane composite material, which includes a matrix and a reinforcement, the matrix is a mixture of silica airgel and polysilazane; the reinforcement is a copolymer of carbon fiber and styrene-vinyl fluoride mixture of things. The styrene-fluoroethylene copolymer is polystyrene-poly1,2,2-trifluorostyrene. Wherein, the mass ratio of the mixture of silica airgel and polysilazane as the matrix to the mixture of carbon fiber and styrene-fluoroethylene copolymer as the reinforcement is 100:80.

[0036] The mixture of silica airgel and polysilazane is prepared by the following method: adding the mixture of polysilazane, methyltriethoxysilane and ethyl orthosilicate to methanol solution, adjusting the pH The value is 5, and supercritical carbon dioxide is introduced to react, and then supercritical drying is carried out to obtain the matrix.

[0037] The mixture of carbon fiber and styrene-fluoroethylene copolymer is prepared by the following m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com