Simulation method for vacancy and interstitial atom defects in iron-copper-manganese-nickel quaternary alloy

A technology of interstitial atoms and quaternary alloys, which is applied in the fields of instrumentation, computational theoretical chemistry, and informatics, and can solve problems such as constrained computational costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

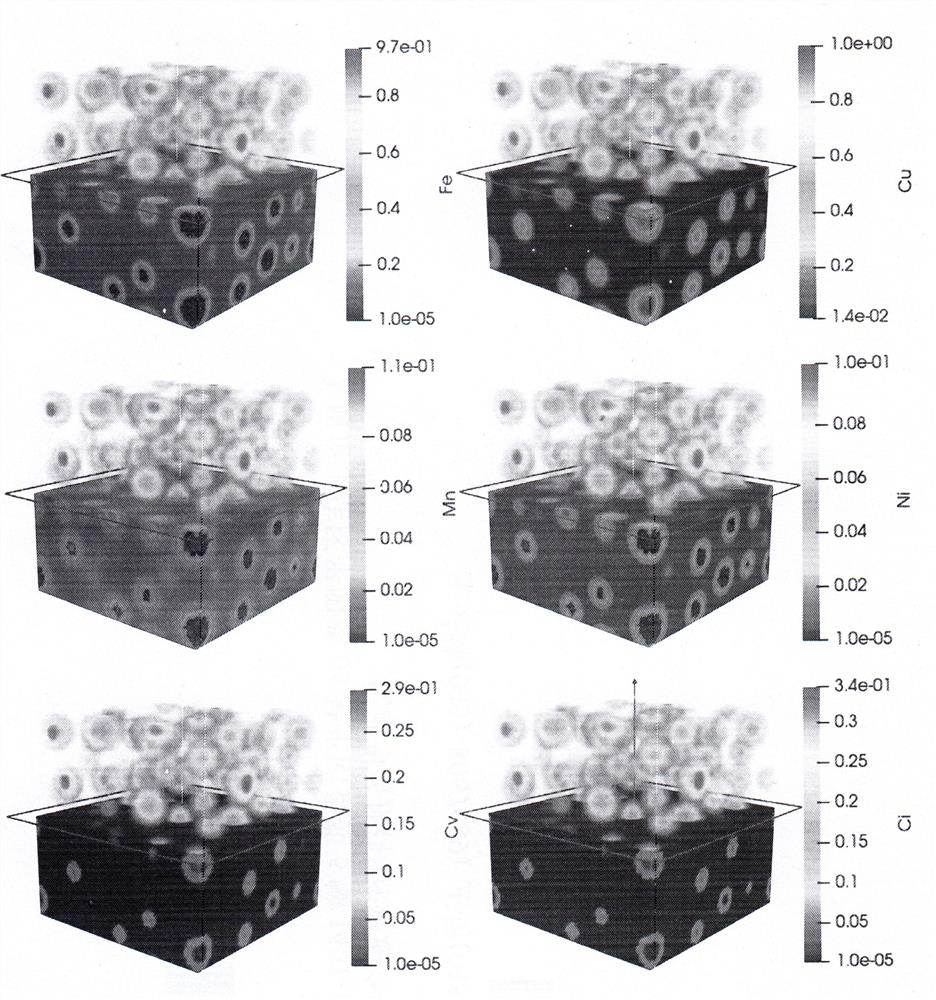

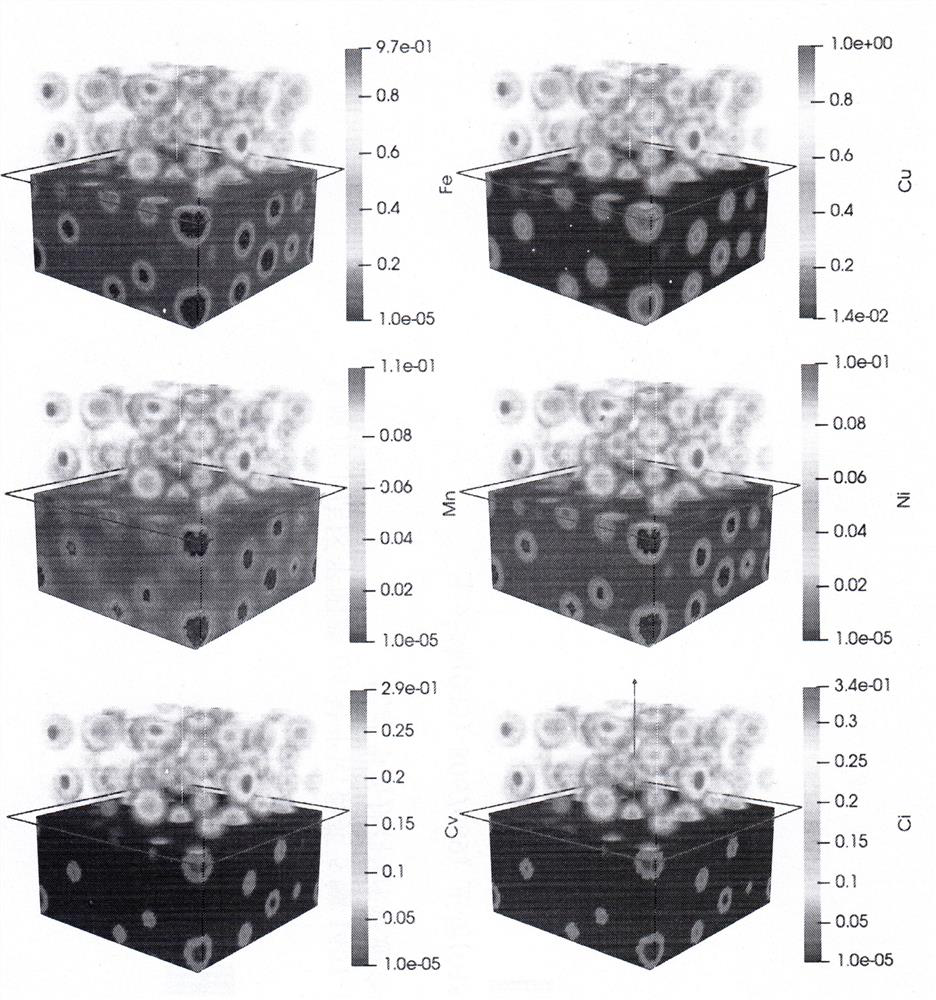

[0043] A method for simulating vacancies and interstitial atom defects in an iron-copper-manganese-nickel quaternary alloy, the method comprising the steps of:

[0044] S1: The establishment of the chemical free energy calculation equation of the iron-copper-manganese-nickel alloy system, the chemical free energy is the chemical free energy that couples the formation energy and concentration of vacancies and interstitial atom defects;

[0045] The establishment of the chemical free energy calculation equation of the iron-copper-manganese-nickel alloy system includes the following contents:

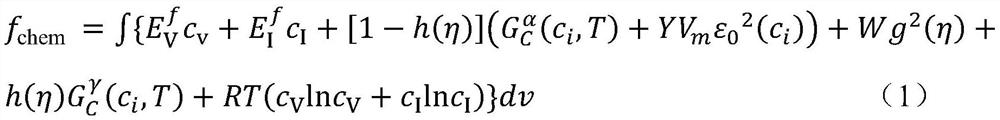

[0046] The chemical free energy f that couples the formation energy and concentration of vacancy and interstitial atom defects chem The calculation equation is:

[0047]

[0048] In the formula, c i is the concentration of component i, i=1, 2, 3, 4, respectively representing Fe, Cu, Mn, Ni, c V is the concentration of vacancies, c I Divided into the concentration of interstitial ato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com