Preparation method of plant-based foam core

A foam core, plant-based technology, applied in the field of preparation of plant-based foam cores, can solve the problems of uneven spreading, ineffective fixation, displacement, etc., and achieve the effects of improving comfort, keeping dryness, and small cell diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

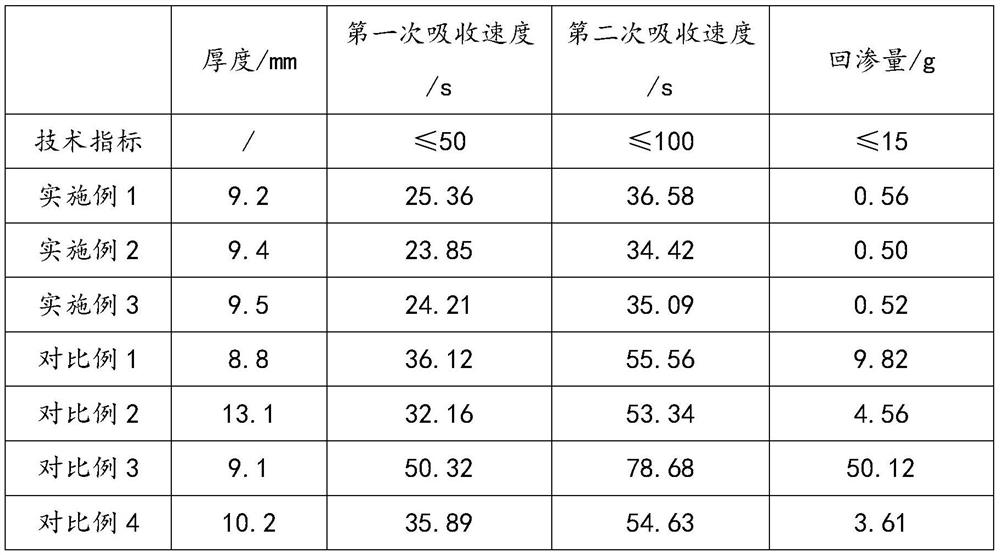

Embodiment 1

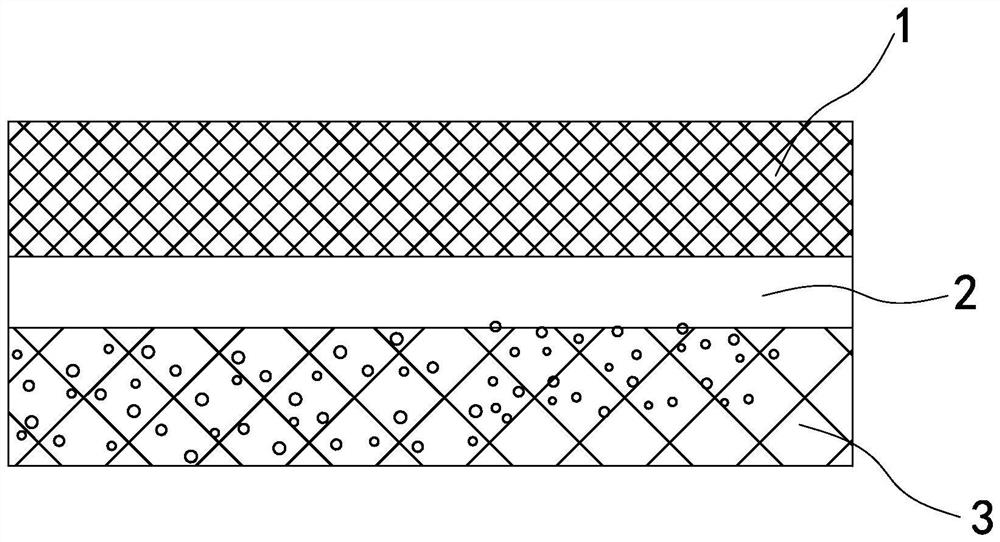

[0036] refer to figure 1 , a plant-based foam core body, which includes an upper foam material layer 1, a middle layer 2 and a lower foam material layer 3 from top to bottom, and the preparation of the plant-based foam core body comprises the following steps:

[0037] S1, preparation of upper foam material layer

[0038] Weigh each raw material according to the following parts by weight: 5 parts of polylactic acid fiber, 30 parts of fluff pulp, 55 parts of nanocellulose-enveloped zinc oxide, 0.6 part of sodium lauryl sulfate, 0.6-3.3 parts of pulp softener, of which nanofiber The preparation process of plain-encapsulated zinc oxide is as follows: put nano-cellulose and nano-zinc oxide into the container according to the mass ratio of 8:2, and perform mechanical stirring under the synergy of ultrasonic waves to achieve good packaging of nano-cellulose on nano-zinc oxide powder. After uniform dispersion, nanocellulose-enveloped zinc oxide is obtained;

[0039] Put the raw mate...

Embodiment 2

[0050] A method for preparing a plant-based foam core, comprising the following steps:

[0051] S1, preparation of upper foam material layer

[0052] Weigh each raw material according to the following parts by weight: 8 parts of polylactic acid fiber, 32 parts of fluff pulp, 60 parts of nanocellulose-enveloped zinc oxide, 1.5 parts of polyacrylamide, 2 parts of pulp softener, wherein nano-cellulose-enveloped zinc oxide The preparation process is as follows: put nano-cellulose and nano-zinc oxide into the container according to the mass ratio of 8:2, and carry out mechanical stirring under the synergy of ultrasonic waves to realize the good wrapping of nano-zinc oxide powder by nano-cellulose and uniform dispersion. Nanocellulose encapsulated zinc oxide;

[0053] Put the raw materials into the reactor according to the above ratio, add deionized water as a solvent, stir and mix for 25 minutes, and foam evenly to obtain the upper foam matrix slurry with a solid content of 12%. ...

Embodiment 3

[0063] A method for preparing a plant-based foam core, comprising the following steps:

[0064] S1, preparation of upper foam material layer

[0065] Weigh each raw material according to the following parts by weight: 10 parts of polylactic acid fiber, 35 parts of fluff pulp, 65 parts of nanocellulose-enveloped zinc oxide, 2.2 parts of sodium dodecylsulfonate, 3.3 parts of pulp softener, wherein nanocellulose The preparation process of enveloping zinc oxide is as follows: put nano-cellulose and nano-zinc oxide into the container according to the mass ratio of 8:2, and carry out mechanical stirring under the synergistic effect of ultrasonic waves to achieve good wrapping and dispersion of nano-cellulose on nano-zinc oxide powder. After uniformity, nanocellulose-enveloped zinc oxide is obtained;

[0066] Put the raw materials into the reactor according to the above ratio, add deionized water as a solvent, stir and mix for 30 minutes, and foam evenly to obtain the upper foam mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com