Boiling-resistant polymer film material and preparation method thereof

A polymer film and cooking-resistant technology, applied in the field of polypropylene composite materials, can solve the problems of general transparency and achieve high thermal stability and purity, high strength, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

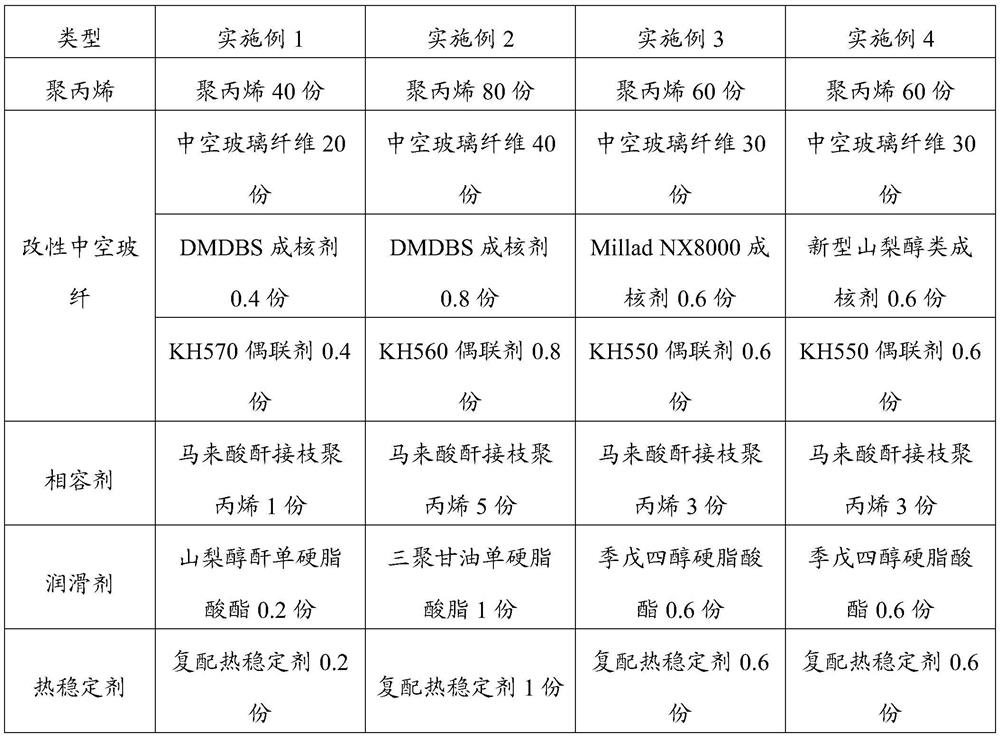

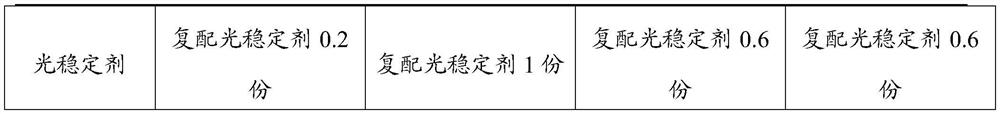

Examples

preparation example Construction

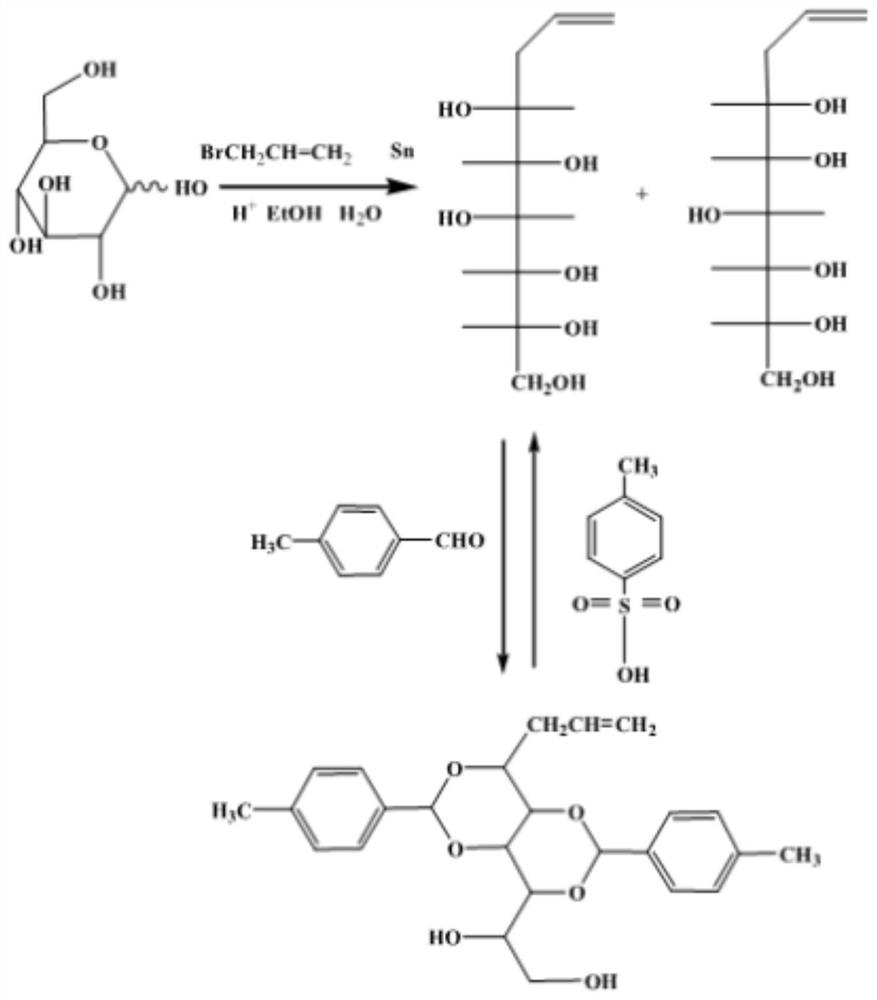

[0047] Wherein, the novel sorbitol nucleating agent of embodiment 4 is 1,3-2,4-bis(p-methylbenzylidene)-1-allyl sorbitol, and its synthetic method comprises the following steps:

[0048] (1) configuration concentration is the HBr alcohol aqueous solution of 0.5mol / L, wherein the volume percentage of ethanol is 10%; With 3 parts of glucose, 2.02 parts of allyl bromide, 1.98 parts of Sn powder, 50 parts of HBr alcohol aqueous solution of 0.5mo / L Place in a reaction kettle, stir and react at room temperature for 48 hours to obtain a mixed solution; add 5 mol / L NaOH aqueous solution dropwise to the mixed solution to neutralize to pH=7, a large amount of white precipitates are formed during the dropping process, and a suspension is obtained; Suction filtration of the suspension was performed to remove the precipitate to obtain a filtrate; the filtrate was subjected to rotary evaporation to remove the solvent to obtain milky white solid 1-allyl sorbitol;

[0049] (2) Put 3.7 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com