Magnesium-aluminum alloy wire hemming type semi-conductive buffer water-blocking tape special for 110KV or above ultrahigh-voltage cable, semi-conductive water-blocking glue and method

A magnesium-aluminum alloy, semi-conductive technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of easy corrosion, poor water resistance, high moisture content, etc., to simplify the production process and overcome the complex process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] 1. Examples of semiconducting resistive hydrocolloids used for water-absorbing water-blocking layers:

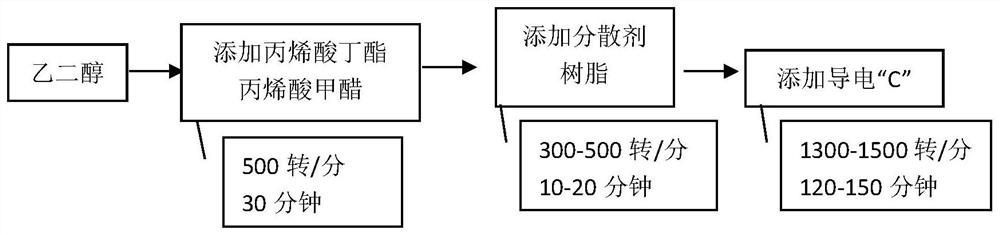

[0046] A semiconducting resistive hydrocolloid for the water-absorbing water-blocking layer of this embodiment, which includes ethylene glycol, butyl acrylate, methyl acrylate, conductive carbon black, dispersant and water-absorbing resin, wherein the ethylene glycol Alcohol is a diluent, and the butyl acrylate and methyl acrylate are binders.

[0047]In a preferred embodiment, the ethylene glycol, butyl acrylate, and methyl acrylate form an anhydrous component binder; the weight ratio of the anhydrous component binder, conductive carbon black, water-absorbent resin, and dispersant is: 10-15: 15-20: 20-30: 1-2; the water-absorbing resin is a water-absorbing powder resin, and the weight ratio of ethylene glycol, butyl acrylate, and methyl acrylate is 3:1 :1.

[0048] In several specific cases, the weight ratio of ethylene glycol, butyl acrylate, methyl acrylate, cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com