Modification method of white carbon black

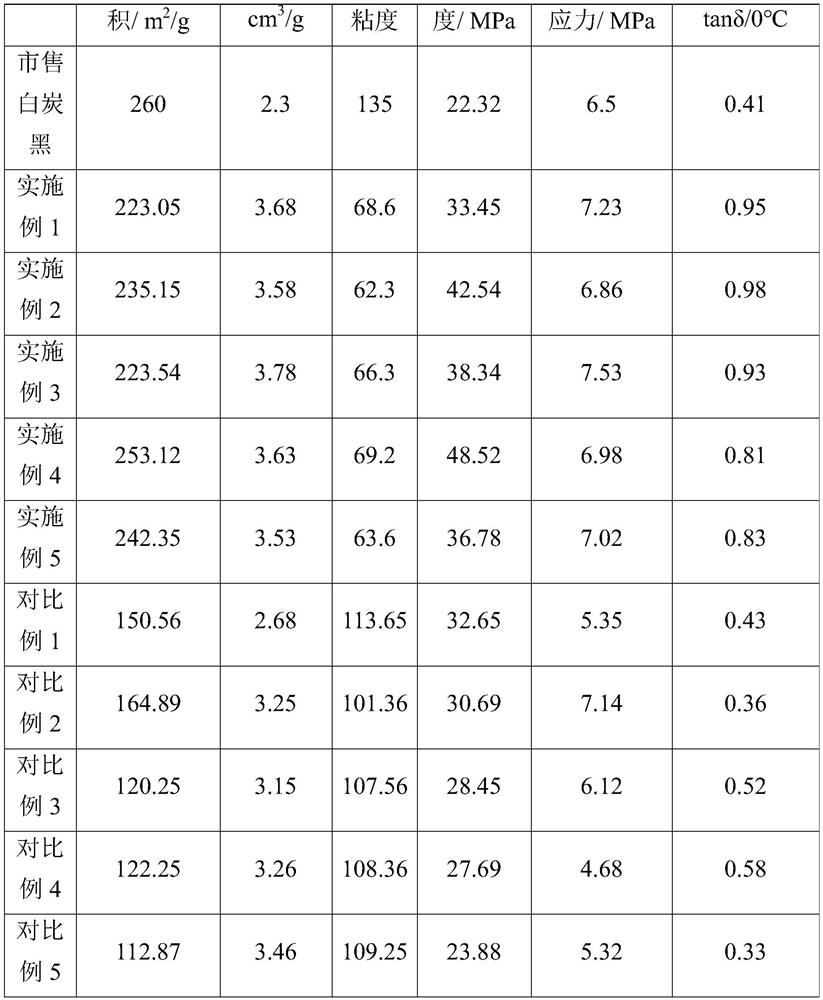

A white carbon black and modified technology, applied in the field of white carbon black, can solve the problems of rubber material loss performance and poor mechanical properties, and achieve the effect of improving mechanical properties and wear resistance, and improving surface area and dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a modification method of white carbon black, the modification method comprising:

[0038] (1) The silica dispersion, glycolic acid (mass concentration is 25%), silane coupling agent (silane coupling agent KH-550) are mixed to obtain the first liquid; the silica dispersion is white carbon Black is obtained by ultrasonic dispersion in ethanol; the content of silica in the silica dispersion is 62%; the addition of the glycolic acid is 11% of the mass of silica in the first liquid; The addition of the silane coupling agent is 20% of the mass of silica in the first liquid; the mixing is carried out under high temperature and high pressure; the mixing pressure is 60MPa; the mixing temperature is 170°C; The mixing time is 2h;

[0039] (2) react the first liquid that step (1) obtains with sodium lignosulfonate under protective atmosphere, obtain modified white carbon black through solid-liquid separation afterwards; The addition amount of described sod...

Embodiment 2

[0041] This embodiment provides a modification method of white carbon black, the modification method comprising:

[0042] (1) The silica dispersion, glycolic acid (mass concentration is 20%), silane coupling agent (silane coupling agent KH-560) are mixed to obtain the first liquid; the silica dispersion is white carbon Black is obtained by ultrasonic dispersion in methanol; the content of silica in the silica dispersion is 55%; the addition of the glycolic acid is 15% of the mass of silica in the first liquid; The addition of the silane coupling agent is 15% of the mass of silica in the first liquid; the mixing is carried out under high temperature and high pressure; the mixing pressure is 40MPa; the mixing temperature is 200°C; The mixing time is 0.5h;

[0043] (2) react the first liquid that step (1) obtains with potassium lignosulfonate under protective atmosphere, obtain modified white carbon black through solid-liquid separation afterwards; The addition amount of describ...

Embodiment 3

[0045] This embodiment provides a modification method of white carbon black, the modification method comprising:

[0046] (1) The silica dispersion, glycolic acid (mass concentration is 30%), silane coupling agent (silane coupling agent KH-570) are mixed to obtain the first liquid; the silica dispersion is white carbon Black is obtained by ultrasonic dispersion in ethanol; the content of silica in the silica dispersion is 70%; the addition of the glycolic acid is 7% of the mass of silica in the first liquid; The addition of the silane coupling agent is 25% of the mass of silica in the first liquid; the mixing is carried out under high temperature and high pressure; the mixing pressure is 80MPa; the mixing temperature is 150°C; The mixing time is 1h;

[0047] (2) react the first liquid that step (1) obtains with sodium lignosulfonate under protective atmosphere, obtain modified white carbon black through solid-liquid separation afterwards; The addition amount of described sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com