Preparation method of high-toughness nano ceramic powder material for oral cavity

A nano-porcelain, high-toughness technology, used in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve the problems of metal-based porcelain restorations, such as broken porcelain and insufficient metal-ceramic bonding strength, and improve the bonding strength and mechanical properties. performance, excellent bonding properties, and the effect of improving the degree of toughening and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

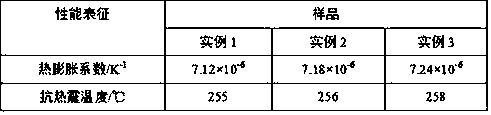

Examples

example 1

[0018] In parts by weight, weigh 45 parts of deionized water, 10 parts of 10% zirconium chloride solution by mass fraction, 10 parts of 5% ammonia solution by mass fraction, and 35 parts of 1% sodium dodecyl sulfate by mass fraction and place them in the triangular In the flask, stir and mix and put it under 200W for ultrasonic dispersion for 10min, get the dispersion liquid and put it under 1500r / min for centrifugation for 10min, get the lower layer precipitate and put it at 110°C for 1h, get the dried product and raise the temperature at 5°C / min Heat at 650°C, heat-preserve and calcinate for 1 hour, let stand to cool to room temperature and grind through a 200-mesh sieve to obtain modified powder; by weight, weigh 45 parts of deionized water, 1 part of magnesium oxide, and 3 parts of modified powder , 6 parts of nano-alumina, 3 parts of polymethacrylic acid, 55 parts of isopropanol, 6 parts of zirconium oxychloride and 3 parts of 1% yttrium nitrate solution by mass fraction a...

example 2

[0020] In parts by weight, weigh 47 parts of deionized water, 12 parts of 10% zirconium chloride solution by mass fraction, 12 parts of 5% ammonia solution by mass fraction, and 37 parts of 1% sodium dodecyl sulfate by mass fraction and place them in the triangle In the flask, stir and mix and place it at 250W for ultrasonic dispersion for 12min, get the dispersion and centrifuge at 1750r / min for 12min, get the lower layer precipitate and dry it at 115°C for 2h, get the dried product and heat up at 5°C / min to 750°C, heat-preserved and calcined for 2 hours, left to cool to room temperature and ground through a 200-mesh sieve to obtain a modified powder; in parts by weight, weigh 47 parts of deionized water, 2 parts of magnesium oxide, and 4 parts of modified powder , 7 parts of nano-alumina, 4 parts of polymethacrylic acid, 57 parts of isopropanol, 7 parts of zirconium oxychloride and 4 parts of 1% yttrium nitrate solution by mass fraction are placed in an Erlenmeyer flask, stir...

example 3

[0022] In terms of parts by weight, weigh 50 parts of deionized water, 15 parts of 10% zirconium chloride solution by mass fraction, 15 parts of 5% ammonia solution by mass fraction, and 40 parts by mass fraction of 1% sodium dodecyl sulfate in a triangular In the flask, stir and mix and place it at 300W for ultrasonic dispersion for 15min, get the dispersion and centrifuge at 2000r / min for 15min, get the lower layer precipitate and dry it at 120°C for 2h, get the dried product and raise the temperature at 5°C / min Calcined at 800°C for 2 hours, left to cool to room temperature and ground through a 200-mesh sieve to obtain modified powder; in parts by weight, weigh 50 parts of deionized water, 2 parts of magnesium oxide, and 5 parts of modified powder , 8 parts of nano-alumina, 5 parts of polymethacrylic acid, 60 parts of isopropanol, 8 parts of zirconium oxychloride and 5 parts of 1% yttrium nitrate solution by mass fraction are placed in an Erlenmeyer flask, stirred and mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com