Treatment system for yellow phosphorus in soil or phosphorus mud and use method

A disposal system, phosphorus sludge technology, applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of increasing the operating load of the flue gas treatment system, the impact on the health of operators, and the ineffective removal of dust and other problems, to achieve the effect of uniform soil turning and throwing, light equipment, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner, but the protection scope of the present invention is not limited to the following embodiments.

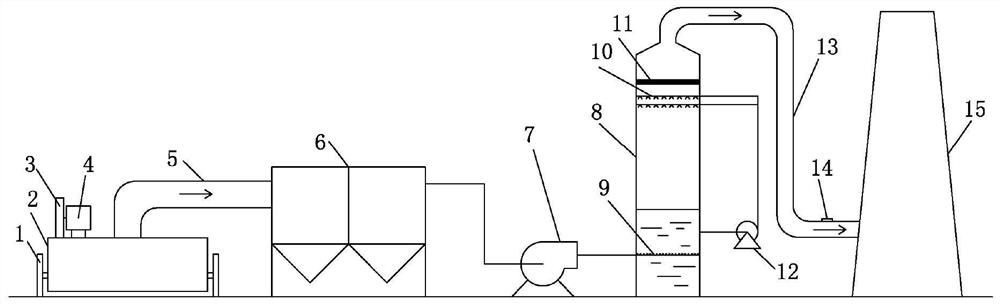

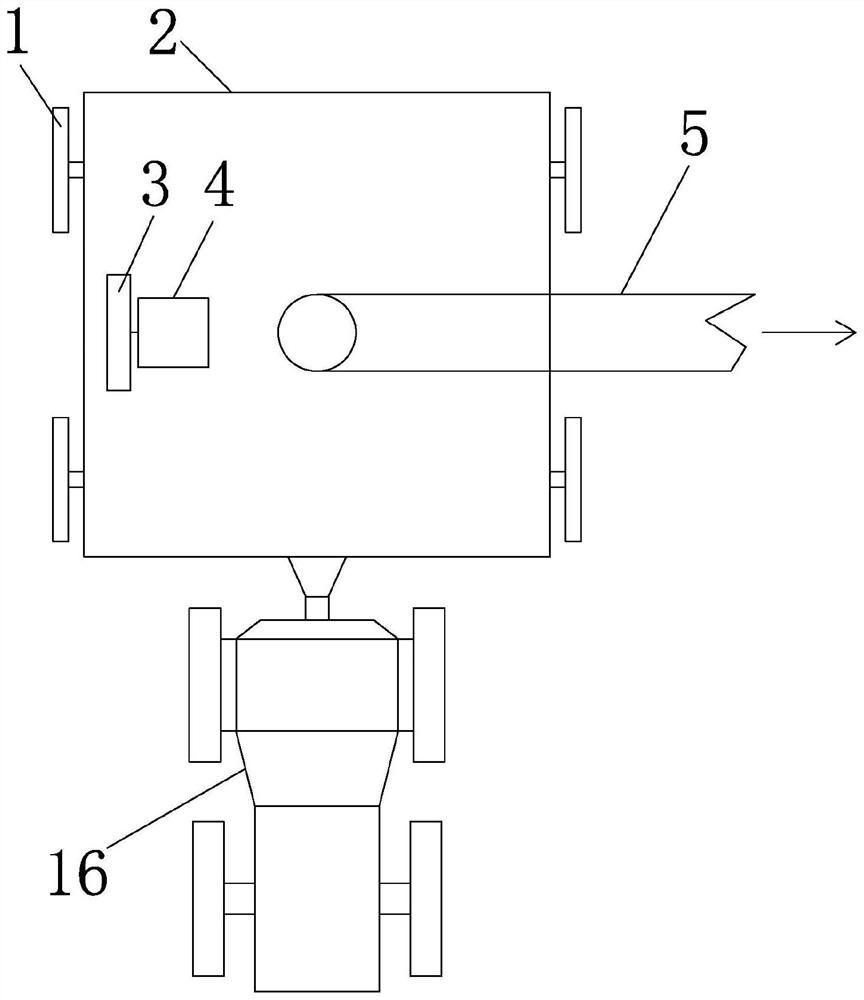

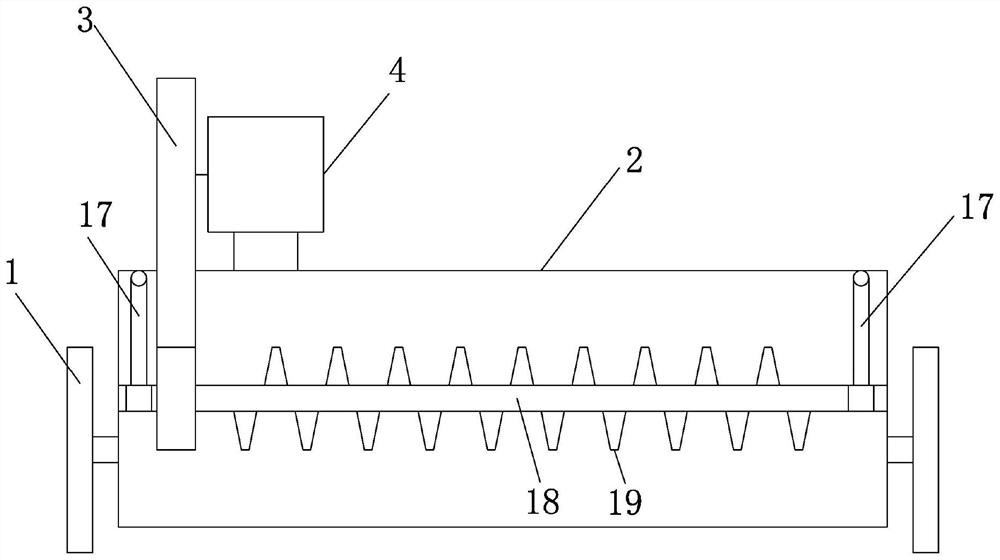

[0027] like Figure 1 to Figure 4 As shown, a yellow phosphorus disposal system in soil or phosphorus mud involved in this embodiment includes: a wheel 1, a turning and throwing frame device 2, a transmission mechanism 3, a turning and throwing drive motor 4, a gas collecting pipe 5, a dust removal device 6, Fan 7, absorption tower 8, gas distributor 9, atomizing nozzle 10, mist eliminator 11, circulating pump 12, pipeline 13, chimney 15, power equipment 16, hydraulic device 17, turning shaft 18 and turning head 19, A wheel 1 is installed below the flipping frame device 2, a flipping driving motor 4 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com