Sludge soil dehydration process and treatment system

A sludge treatment and sludge technology, applied in the field of sludge soil dehydration process and treatment system, can solve the problems of high energy consumption, high treatment cost, large investment in equipment and site, etc., to achieve convenient on-site treatment, improve flocculation effect, dehydration The effect of effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

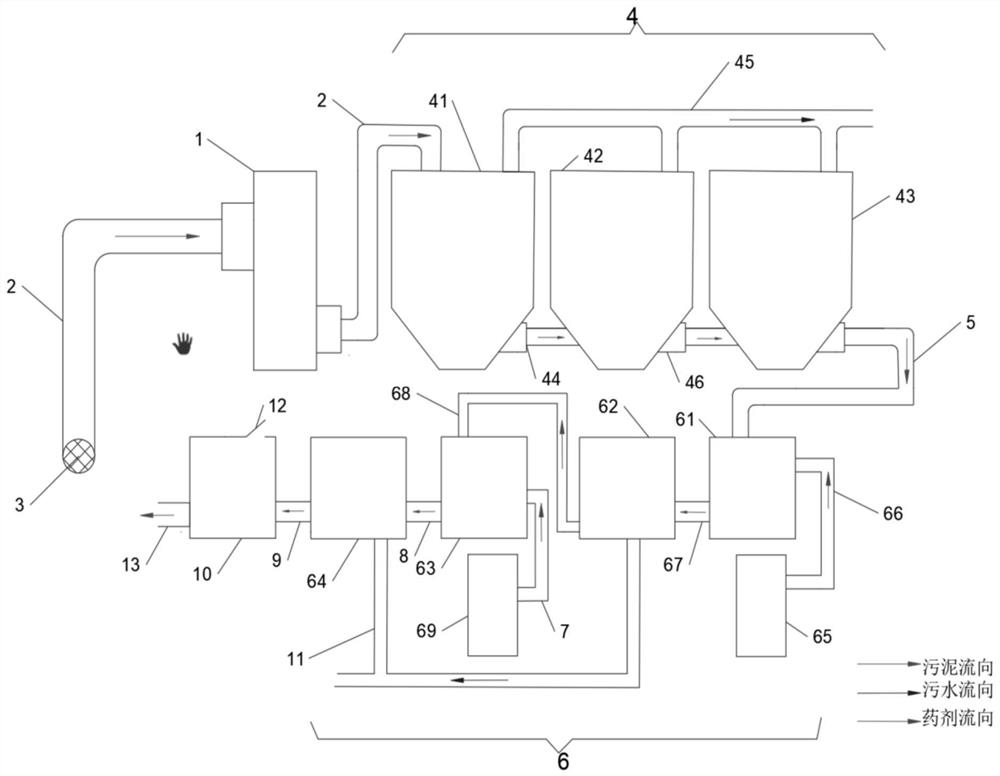

[0041] Such as figure 1 As shown, a mobile sludge soil dewatering system includes a buccular system, a flocculation precipitation system 4, a multi-segment sludge conditioning dewatering system 6;

[0042] The flocculating precipitation system 4 includes a tube flocculating precipitation apparatus A41, a tube flocculating precipitation apparatus C43, a tube flocculating precipitation apparatus C43, and a tube flocculating precipitation apparatus A41, a tube flocculating precipitation apparatus A41, a raw tube flocculation precipitation Equipment C43 has a flocculant addition port and drain outlet;

[0043]The multi-segment sludge conditioning dewatering system 6 includes a silt regulatory chamber A61, a belt filter press A62, a sludge conditioning chamber B63, a belt filter press B64, and a silt regulation chamber C10;

[0044] The sludge conditioning chamber A61, the sludge conditioning chamber B63 and the silt regulation chamber C10 are each provided with a dose of a dose; the b...

Embodiment 2

[0052] Silled Soil Soil Dehydration Process, Silk Soil Dehydration Process Use the sludge treatment system according to any one of claims 1-6, including:

[0053] (1) Extracting silt flocculation precipitation device A from the river

[0054] (2) Adding a polyacrylamide in the tube flocculation precipitation device A for the first flocculation precipitation, the amount of polyacrylamide is added to the sludge of 30 mg of polyacrylamide, the first flocculation of the first flocculation precipitated supernatant The drain is discharged, and the first flocculation precipitated silt into the tube flocculation precipitation device B;

[0055] (3) The second flocculation precipitation is carried out in the raw tube flocculation precipitation device B, and the second flocculation precipitation is carried out by the second flocculation precipitation. The drain is discharged, and the second flocculation precipitated sludge enters the tube flocculation precipitation device C;

[0056] (4) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com